High voltage battery charger power module and circuit

A power module and storage battery technology, applied in the direction of output power conversion device, DC power input conversion to DC power output, AC power input conversion to DC power output, etc., can solve the problem of high cost, difficult implementation and lack of versatility of IGBT and other problems, to achieve the effect of reasonable layout, meeting heat dissipation requirements, and saving design and development investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

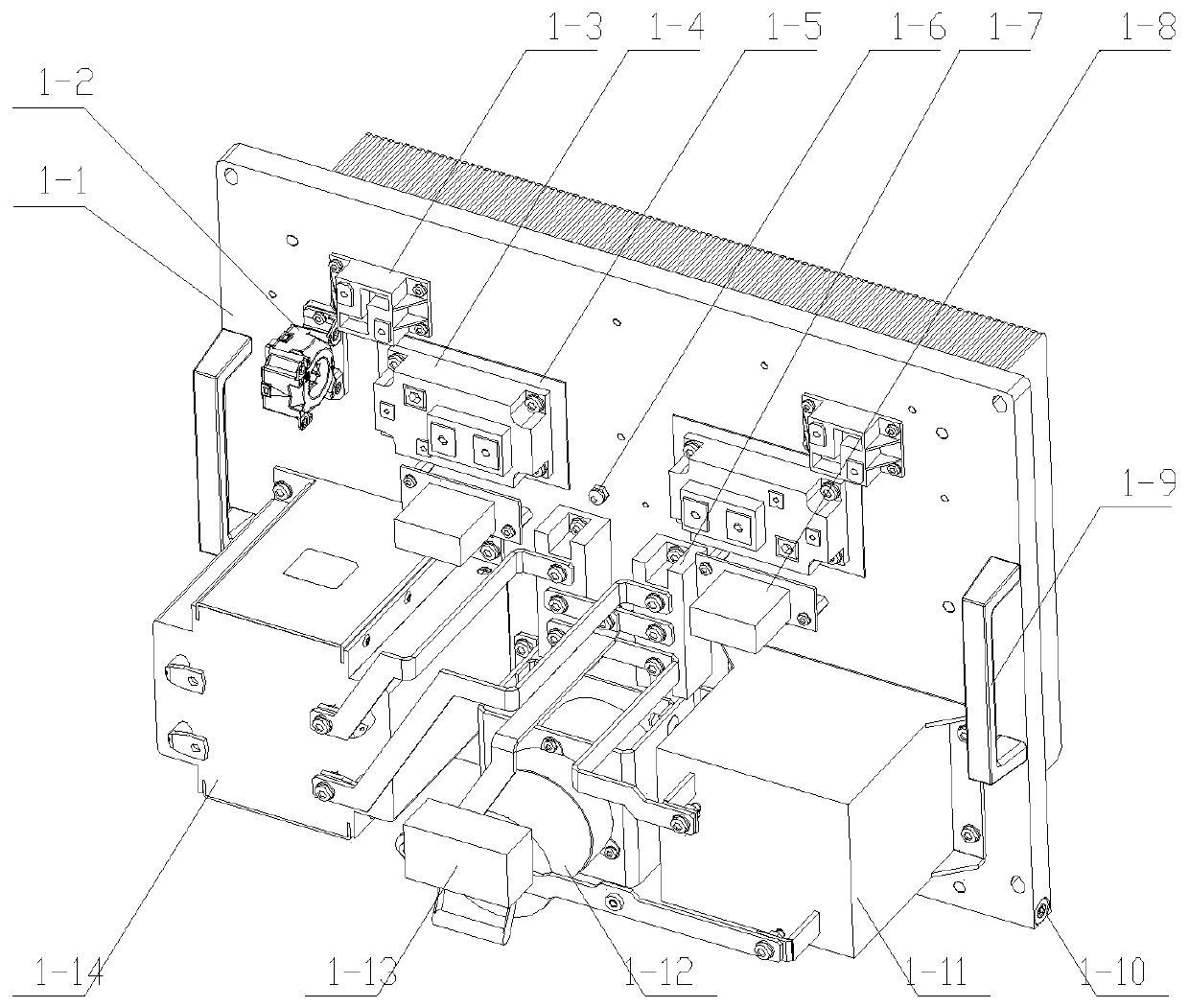

[0035] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

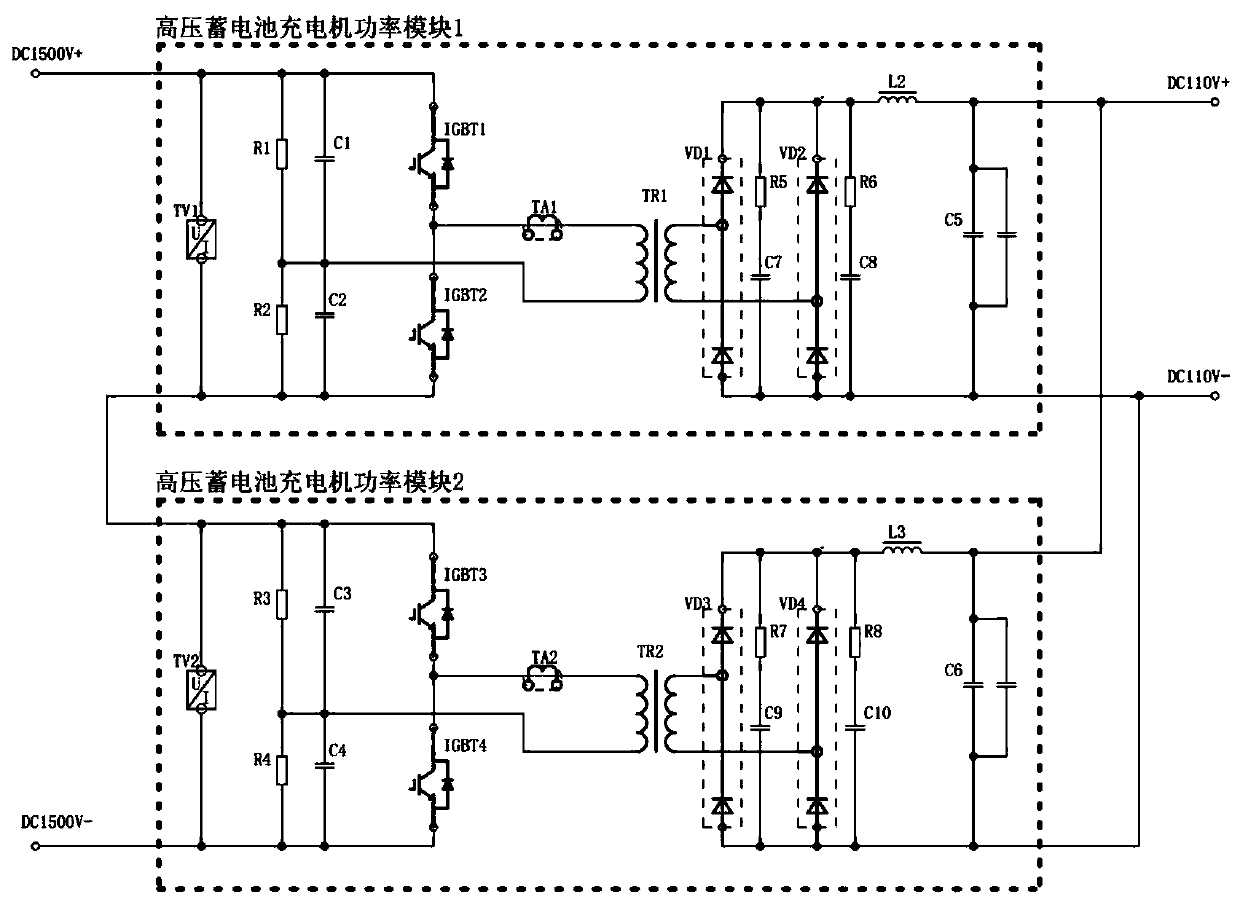

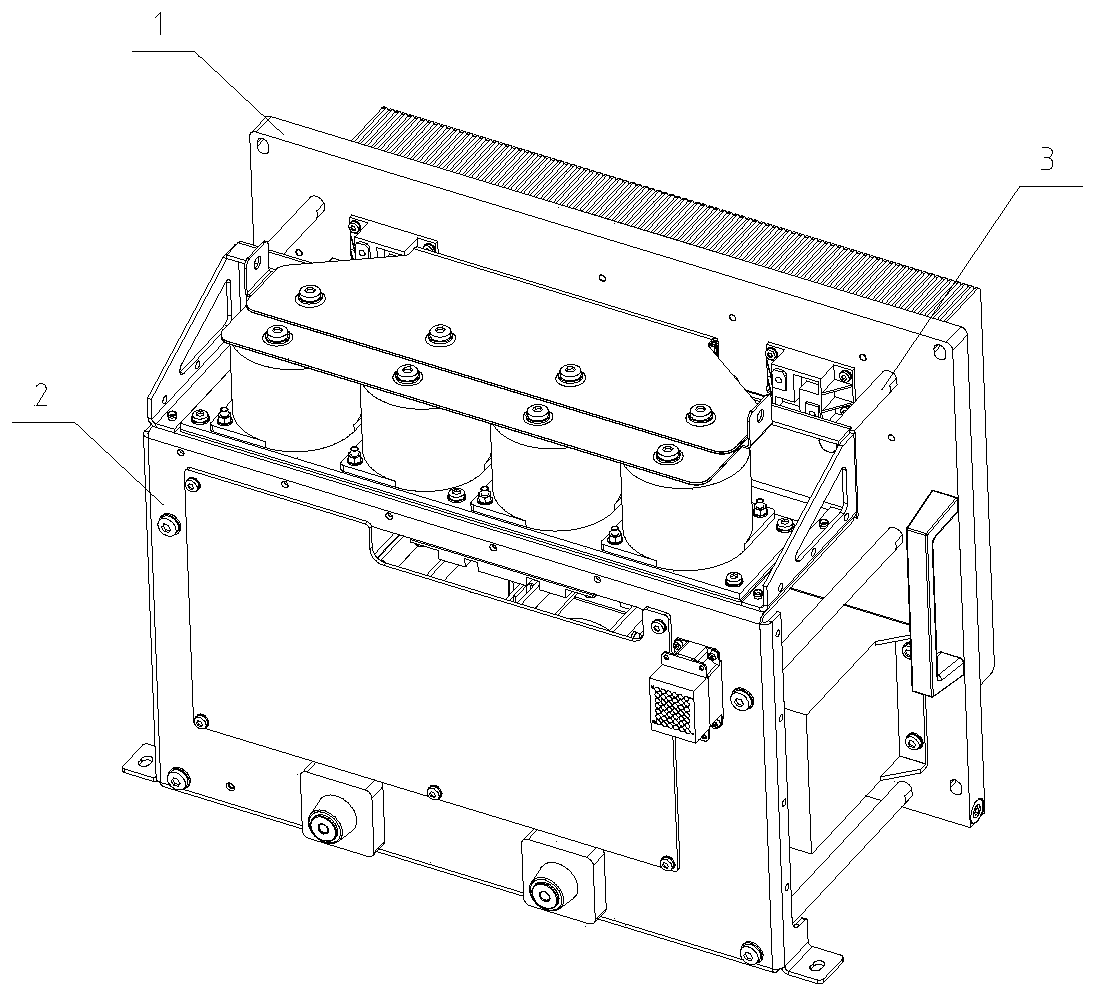

[0036] The invention provides a power module and circuit of a high-voltage battery charger, which is used for a high-voltage battery charger with a multi-module series topology. The multi-module topology can reduce the power of a single module, reduce the voltage stress of power devices, and realize multi-module interleaved control , to reduce output ripple, is the ideal topology. But even if multiple modules are connected in series, the insulation withstand voltage of the power device IGBT still needs to meet the standard requirements of the DC1500V system. The insulation withstand voltage of the current 1700V class IGBT can only reach 4000V, which cannot meet the standard requirements of the DC1500V system. Therefore, the present invention provides a high-voltage battery charger power module on the basis of comprehensive consideration of insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com