A kind of silicone rubber heat-conducting composite material containing graphene and preparation method thereof

A technology of heat-conducting composite materials and graphene, which is applied in the field of heat-conducting polymer composite materials, can solve problems such as the deterioration of the mechanical properties of silicone rubber, and achieve the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of the above-mentioned graphene / inorganic heat-conducting filler composite heat-conducting silicone rubber material is as follows: firstly, on a double-roll mill, inorganic heat-conducting fillers, graphene, cross-linking agents and other additives are mixed evenly with silicone rubber to obtain heat-conducting silicone rubber pre-mixed. Polymer. Then put the above-mentioned prepolymer on a flat vulcanizing machine for hot pressing to obtain a section of vulcanized heat-conducting silicone rubber. Then put the above-mentioned one-stage vulcanization product into an oven for two-stage vulcanization, and finally obtain the composite heat-conducting silicone rubber. The method specifically includes the following steps:

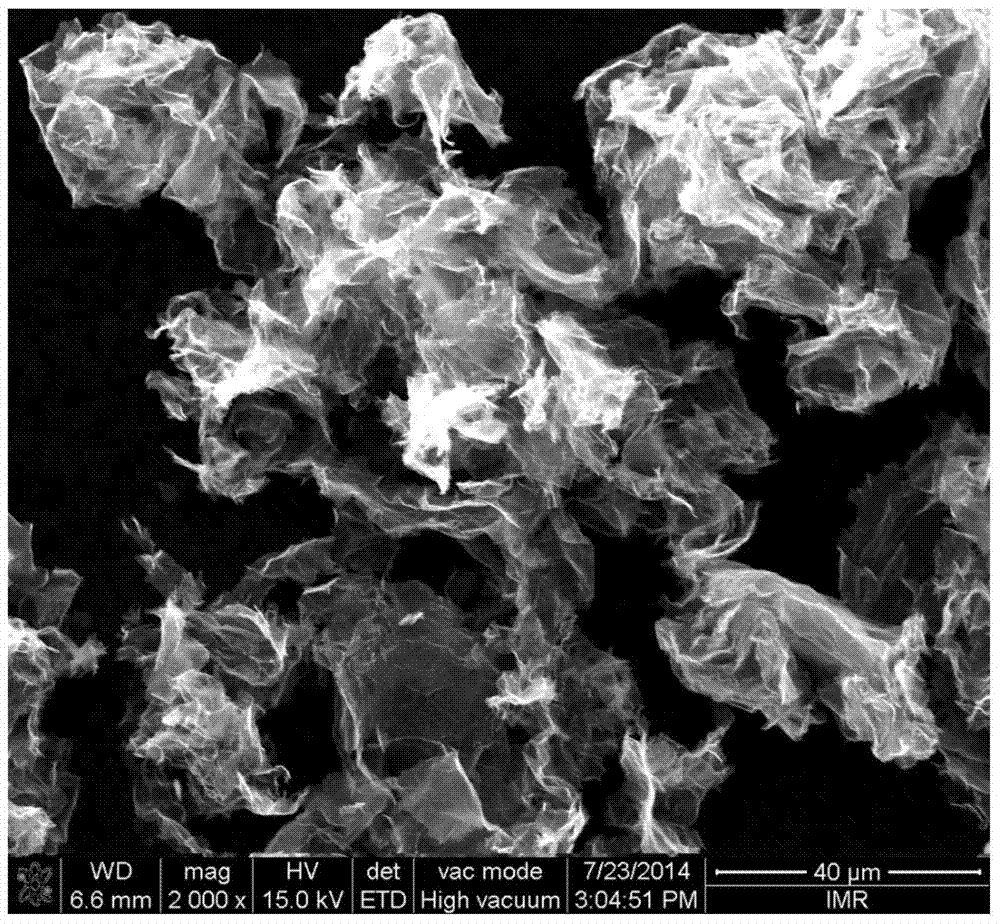

[0043] (1) Preparation of surfactant-treated graphene: first surfactant is added to deionized water, surfactant by weight: water=0.1~3:100, to obtain an aqueous solution containing surfactant; then under stirring condition Add grap...

Embodiment 1

[0051] In this embodiment, a graphene / aluminum oxide composite thermally conductive silicone rubber composite material is prepared, and the content of graphene in the composite thermally conductive film material is 5.0 wt%.

[0052] First, add 10 grams of methyl vinyl silicone rubber to the double-roller mill and mix evenly, then add 3 grams of fumed silica, 45 grams of aluminum oxide treated with silane coupling agent KH-550 and silane 3.0 grams of graphene treated with coupling agent KH-550, 0.20 grams of cross-linking agent 2,5-dimethyl-2,5 di-tert-butylperoxyhexane (double 2,5), etc. are mixed until uniform to obtain thermal conductivity Silicone rubber prepolymer. The obtained heat-conducting silicone rubber prepolymer was placed on a flat vulcanizing machine and hot-pressed at 165° C. and 10 MPa for 10 minutes to obtain a stage of vulcanized heat-conducting silicone rubber. Then put the obtained one-stage vulcanized heat-conducting silicone rubber into an oven for two-s...

Embodiment 2

[0055] In this embodiment, a graphene / aluminum oxide composite thermally conductive silicone rubber composite material is prepared, and the content of graphene in the composite thermally conductive film material is 3.3 wt%. Other preparation methods are the same as in Embodiment 1, and the measured thermal conductivity of the composite thermally conductive silicone rubber is 2.28w / m·k (40°C).

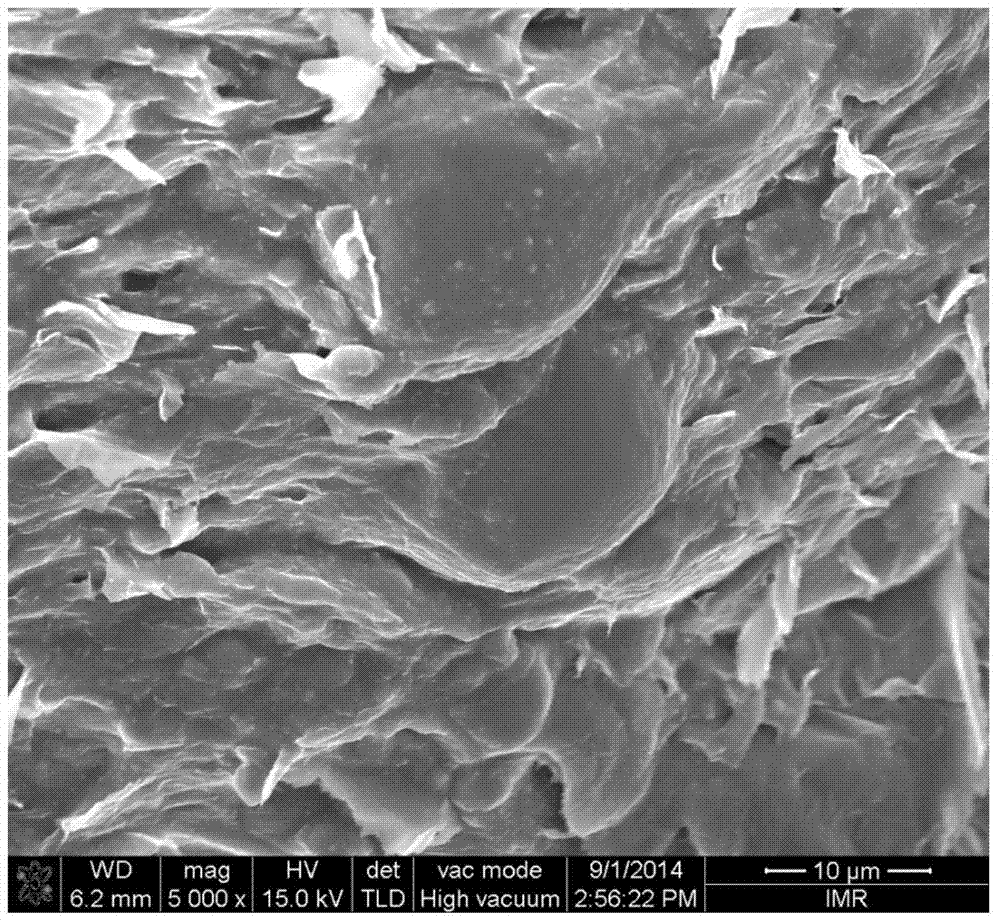

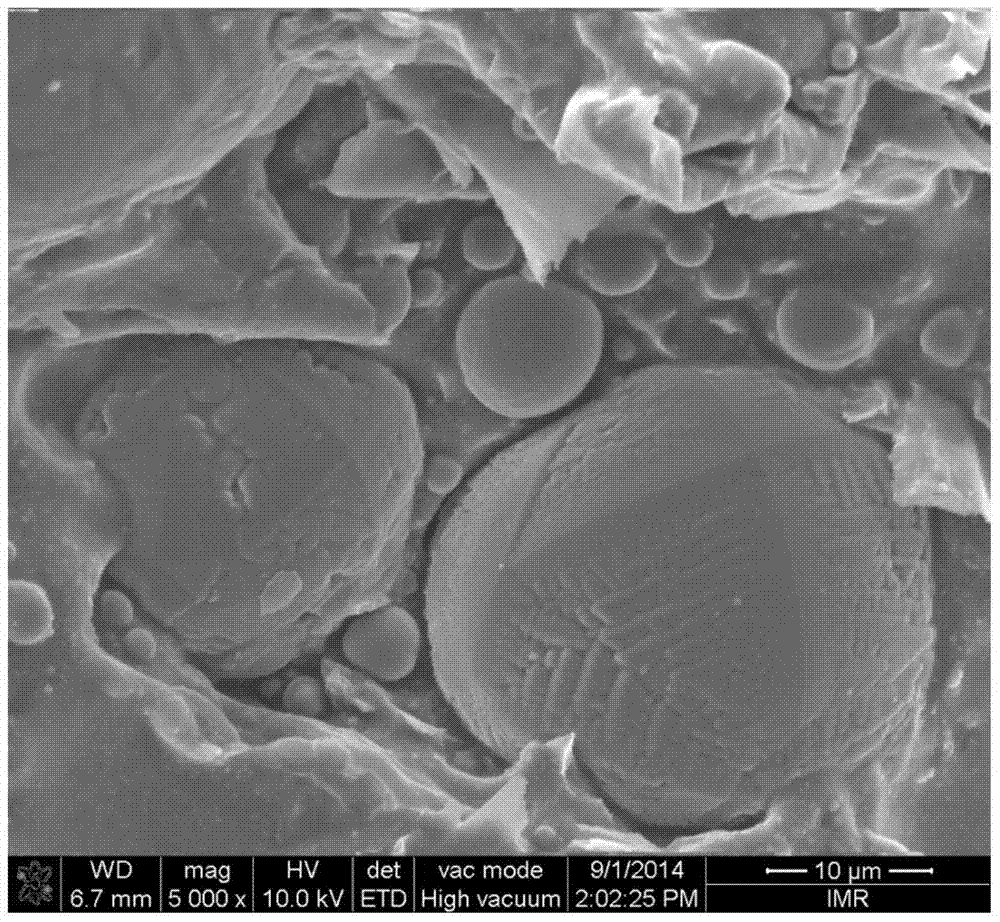

[0056] Such as image 3 As shown, it can be seen from the scanning electron microscope photo of the graphene / aluminum oxide composite thermally conductive silicone rubber material that graphene and aluminum oxide are evenly distributed in the silicone rubber and form a composite thermally conductive network.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com