Livestock carcass skin marking device, system and marking method

A livestock and carcass technology, applied in slaughtering devices, marked meat/sausage, slaughtering accessories, etc., can solve the problems of high frequency response, complex fluid handling system, low precision and high speed, etc., to achieve low equipment cost, ensure food safety, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

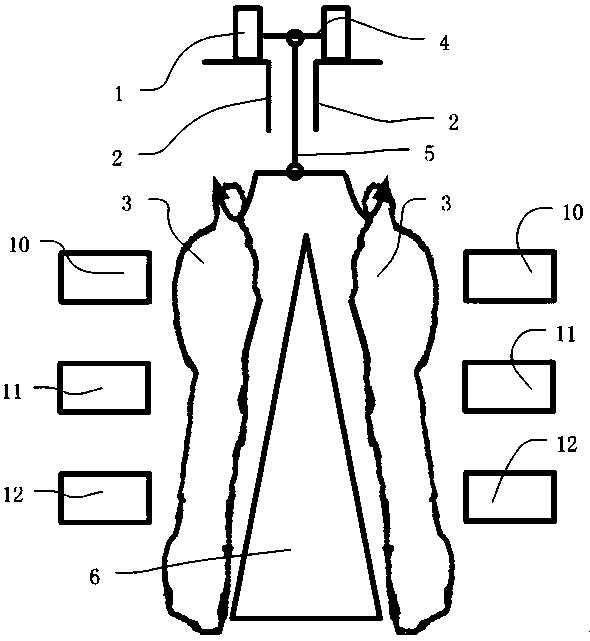

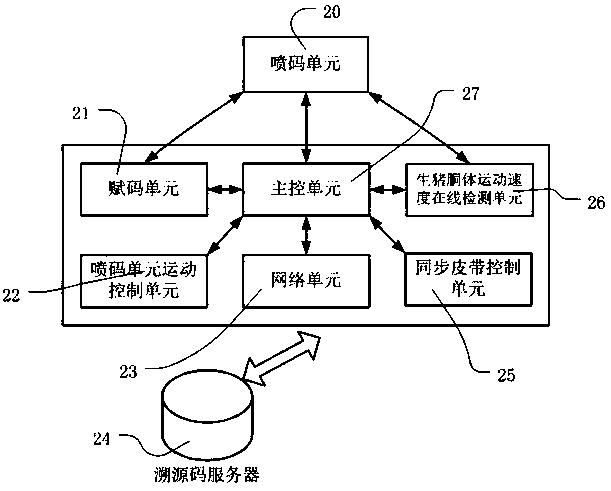

[0045] figure 2 It is a system frame diagram of the present invention. In order to allow the inkjet unit 20 to complete the inkjet marking on the skin of the pig, the pig on the hook must be allowed to move forward smoothly, and a certain relative speed of movement must be maintained between the nozzle and the pig. When the pig is detected, the inkjet is started. The system mainly includes a main control unit 27, a coding unit 20, a code assignment unit 21, a coding unit motion control unit 22, a network unit 23, a synchronous belt control unit 25, and an online detection unit 26 for the movement speed of a pig carcass. The main control unit 27 obtains the traceability code from the traceability code server 24 through the network unit 23, generates a spray-printed image through the coding unit 21, and prints the spray-printed image on the pork skin t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com