A waste gas purification spraying device

A spray device and exhaust gas purification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high spray intensity, large size, and high power consumption, and achieve enhanced spray effect, liquid Fine drop, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

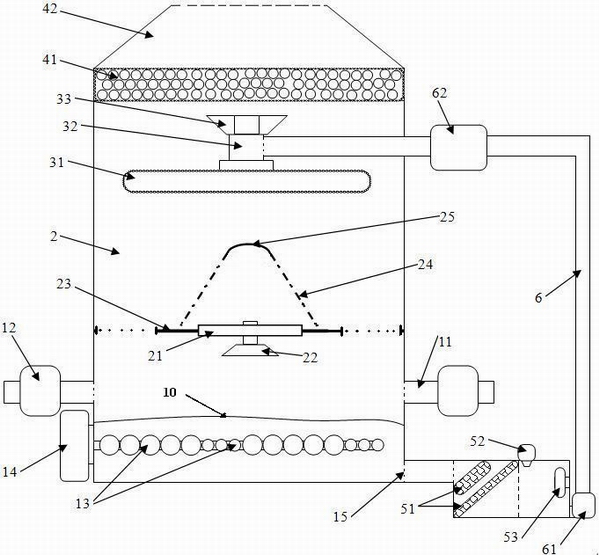

[0033] Such as figure 1 shown.

[0034] A spraying device for purifying exhaust gas, comprising a spraying device shell, an atomization area, a spraying area, a filter adsorption layer, a treatment gas outlet area and a water circulation device.

[0035] The casing of the shower device is a superimposed structure of an upper hollow frustum and a lower hollow cylinder, and the top of the casing of the shower device is opened as a clean gas discharge port.

[0036] The atomization area is set in the lower half of the spray device shell, including the main air intake pipe, air intake fan, ceramic atomizing sheet, electronic high-frequency oscillation generator and sewage outlet.

[0037] There are two total air intake pipes, both of which are arranged on the side wall of the spray device shell (relatively arranged), and an air intake fan is arranged on each general air intake pipe; There are 32 (2 rows, 16 pieces in each row) ceramic atomizing sheets horizontally arranged insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com