Organosilicone fluidized bed reactor

A silicon fluidized bed and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problem that the reactants cannot fully react, and achieve the effect of accelerating heat dissipation and promoting the reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

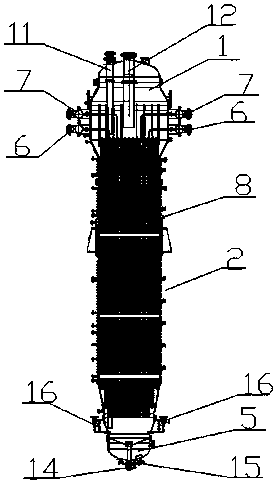

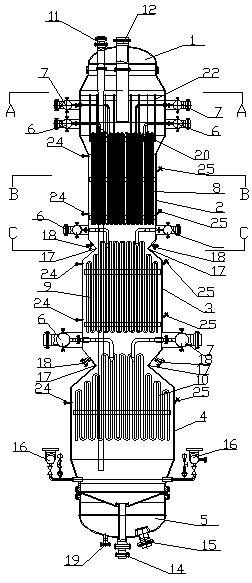

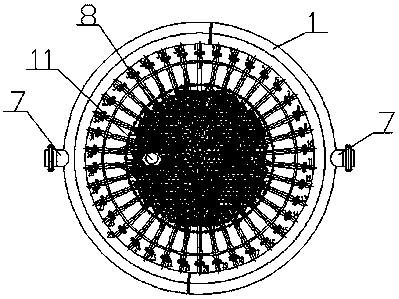

[0025] This embodiment provides an organosilicon fluidized bed reactor, such as Figure 2 to 5 As shown, the reactor is mainly composed of an upper head 1, a first cylinder 2, a second cylinder 3, a third cylinder 4, and a lower head 5 arranged in sequence from top to bottom. The product gas outlet 11 and the solid material inlet 12 are provided; the diameters of the first cylinder 2, the second cylinder 3 and the third cylinder 4 increase in sequence, and the cylinder diameter of the second cylinder 3 is the same as that of the first cylinder 2. 1.2 times the cylinder diameter, the cylinder diameter of the third cylinder 4 is 1.5 times the cylinder diameter of the first cylinder 2; the junction of the first cylinder 2 and the second cylinder 3 and the second cylinder 3 and the third cylinder The joints of the cylinder 4 are all concave structures 17.

[0026] A first heat exchange tube 8 arranged in an S-shaped fold is fixed in the first cylinder 2 through three grids 20 arrang...

Embodiment approach 2

[0030] This embodiment is a further improvement of Embodiment 1. The main improvement is that, in Embodiment 1, the diameters of the first heat exchange tube 8, the second heat exchange tube 9 and the third heat exchange tube 10 are the same, and In the first cylinder 2, the second cylinder 3, and the third cylinder 4, the distances between the pipes of the three heat exchange tubes are equal, and since the reaction in the third cylinder 4 in the reactor is the most intense, the more Up to the second cylinder 3 and the first cylinder 2, the intensity of the reaction gradually decreases. If the diameters of the three heat exchange tubes in the three cylinders are the same and the distance between the tubes is equal, the heat exchange efficiency is basically the same , And the heat generated by the reaction in the three cylinders decreases at once, so the design is not conducive to reasonable heat dissipation. In this embodiment, the reasonable arrangement of the three heat excha...

Embodiment approach 3

[0036] This embodiment is a further improvement of the second embodiment. The main improvement is that in the second embodiment, the higher the pressure of the silicone fluidized bed reactor, the lower the pressure and the lower the temperature, and the higher the reaction effect, the higher Poor; In order to effectively improve the above-mentioned situation, in this embodiment, four openings are provided in a circle at the two concave structures 17 and the gas booster nozzle 18 inclined to the upper part of the inside of the cylinder is used for injection and bottom high temperature The gas inlet 15 is the same high-temperature gas. In this embodiment, the two-stage gas pressurization nozzle 18 is used to pressurize the gas to ensure that the reactants continue to rise, so that the upper cylinder (the second cylinder 3 and the first cylinder 2) The reactant can also react completely under sufficient conditions; the gas inlet of the gas booster nozzle 18 can be adjusted in real ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com