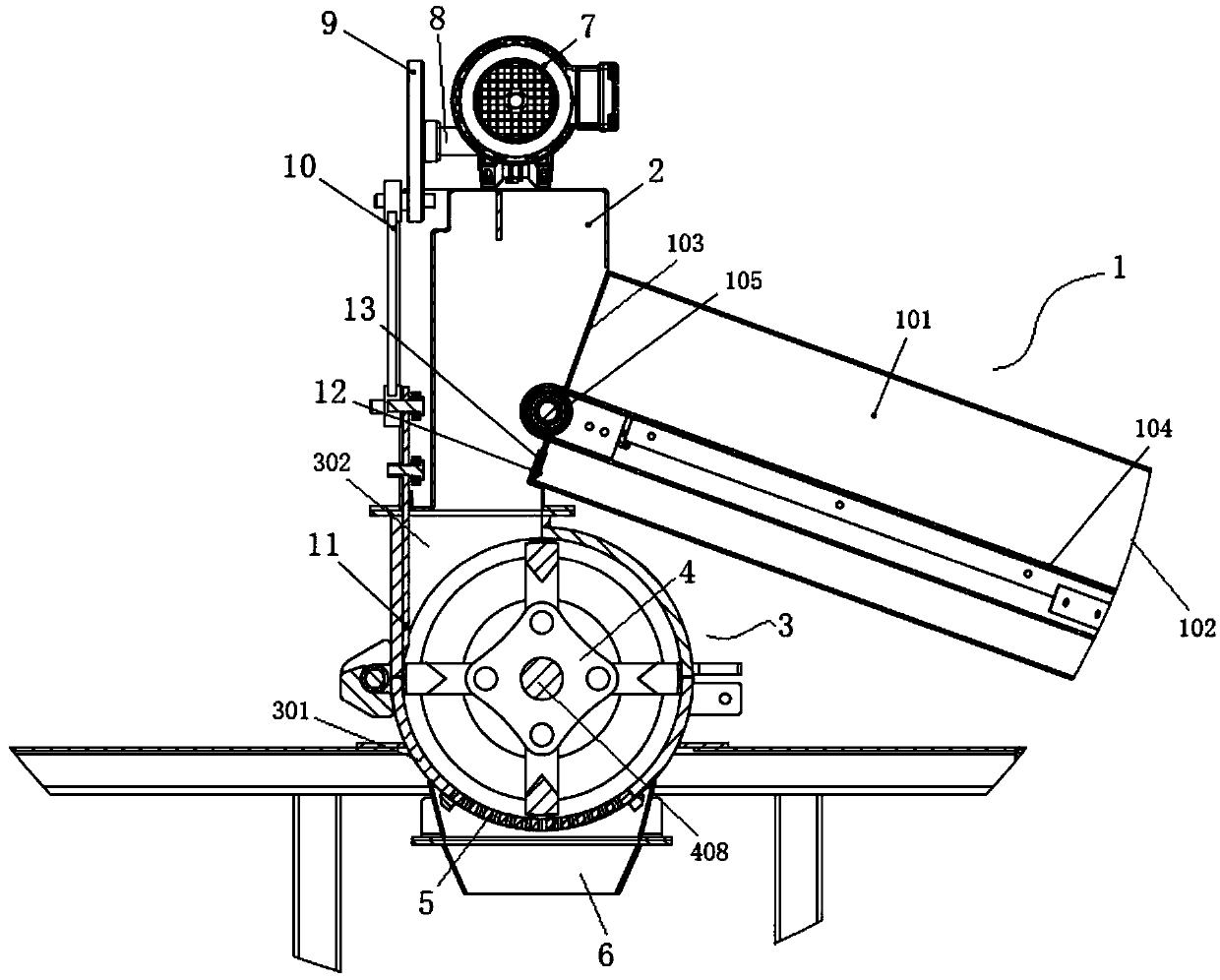

Primary feeding mechanism

A technology of feeding mechanism and feeding hopper, applied in the direction of analyzing materials, conveyor objects, cleaning devices, etc., can solve the problems of inability to clean up coal deposits in equipment, inability to control the accuracy of coal feeding, affecting sampling quality, etc., and achieve a reasonable design structure. , Easy to use and maintain, and the effect of increasing sampling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

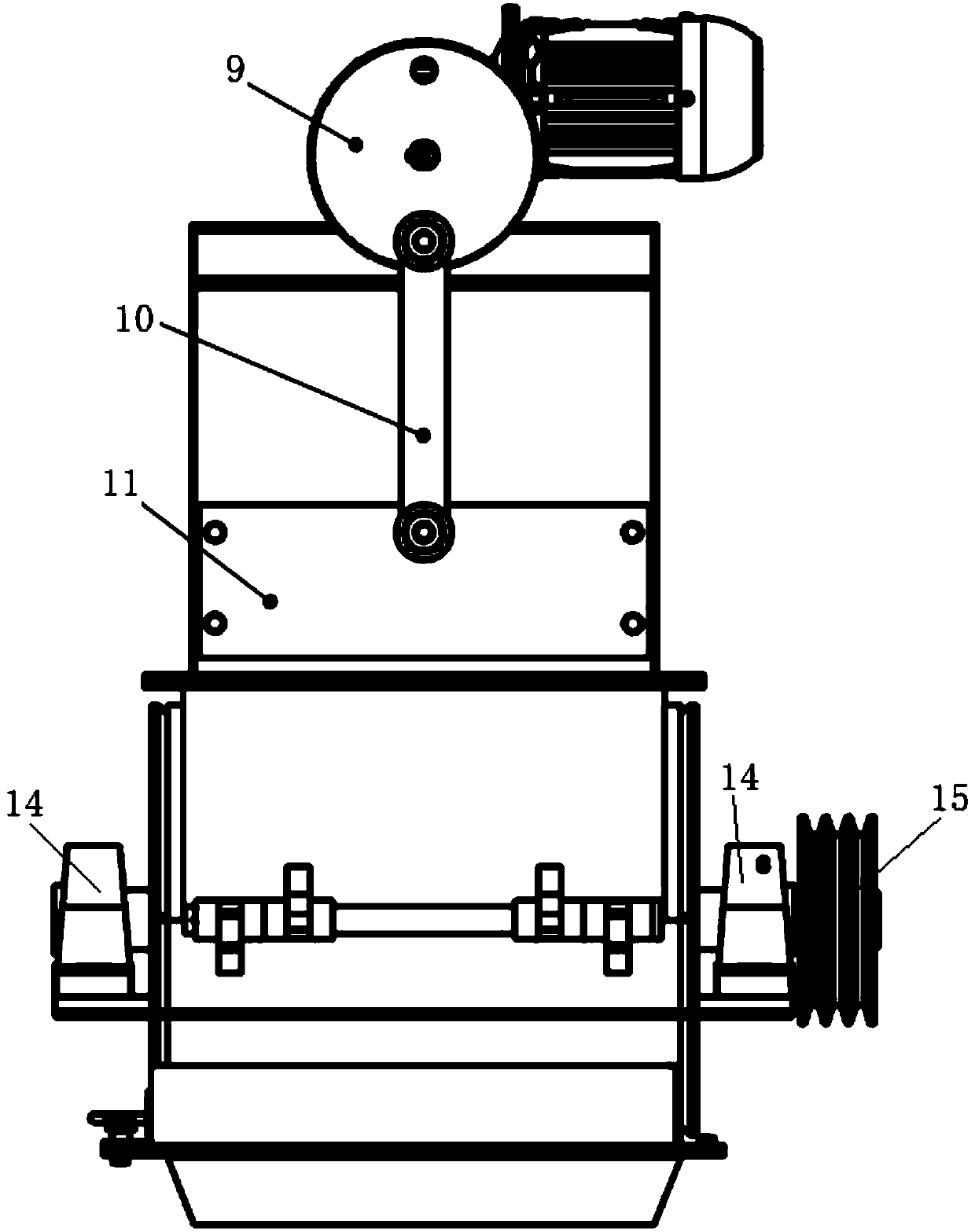

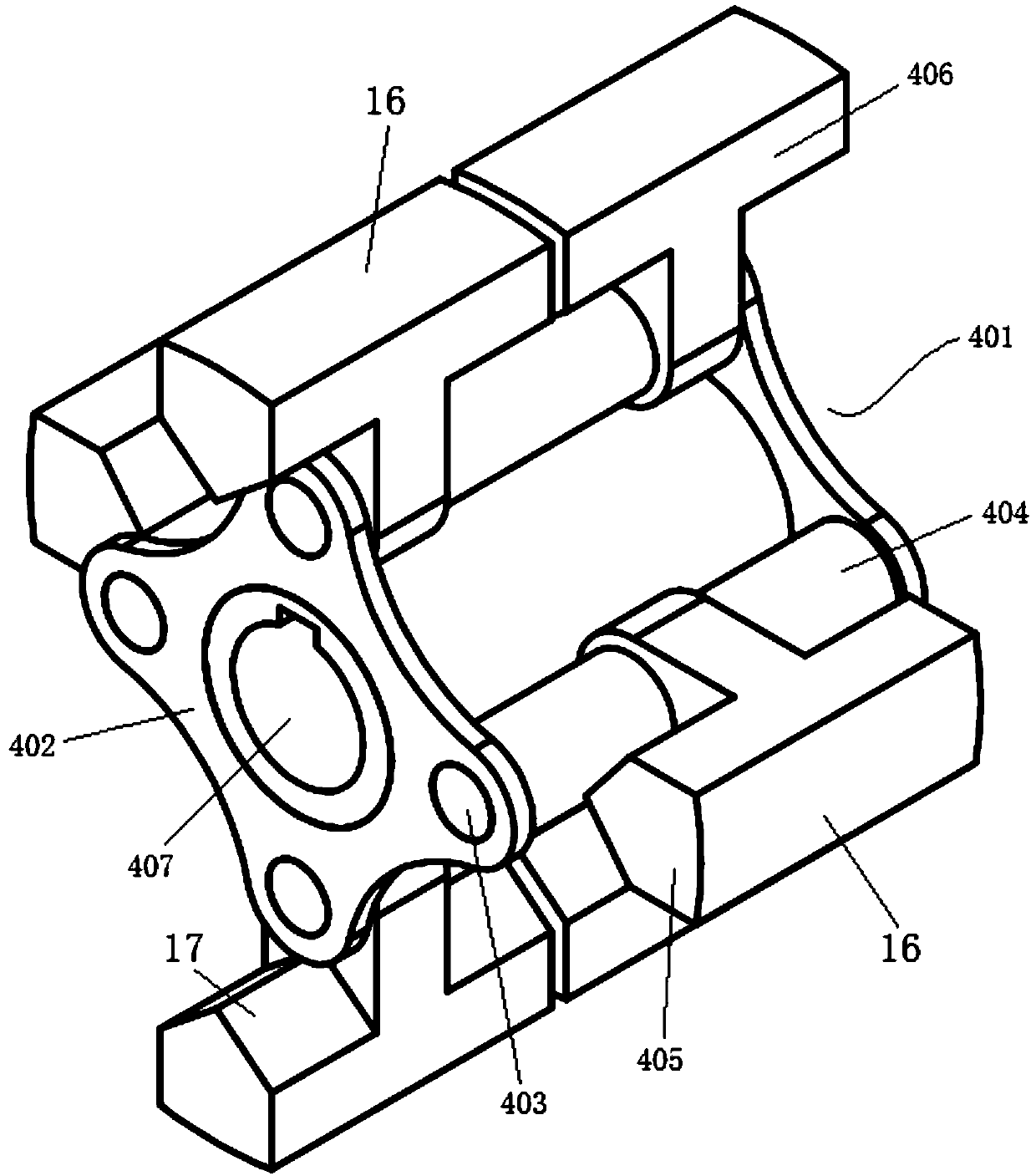

[0024] When in use, the coal mine that needs quality inspection and sampling is put on the conveyor belt of the conveyor conveyor inlet, and the coal mine is sent to the conveyor outlet via the conveyor belt, enters the guide trough through the hopper, and then enters the crusher cabin. At this time, the shaft of the crusher is driven by the rotation of the belt pulley to drive the fixed rod on the pendulum seat fixed on the rotating plate to rotate together through the flat key. Since the fixed rod and the pendulum sleeve are movably sleeved, the pendulum sleeve is fixed The first pendulum and the second pendulum are all stretched under the action of centrifugal force, and continue to rotate in the cabin to crush the coal mine. The crushed coal mine falls from the screen to the lower hopper.

[0025] The first pendulum and two second pendulums are arranged at intervals. Since the first pendulum is arranged in the middle and the length is smaller than the length of the cabin, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com