Chip gravity test tube reversing auxiliary tool

A technology of gravity testing and auxiliary tools, applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve the problems of low operation efficiency, loss, long length, etc., and achieve the effect of improving operation efficiency, stable positioning, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

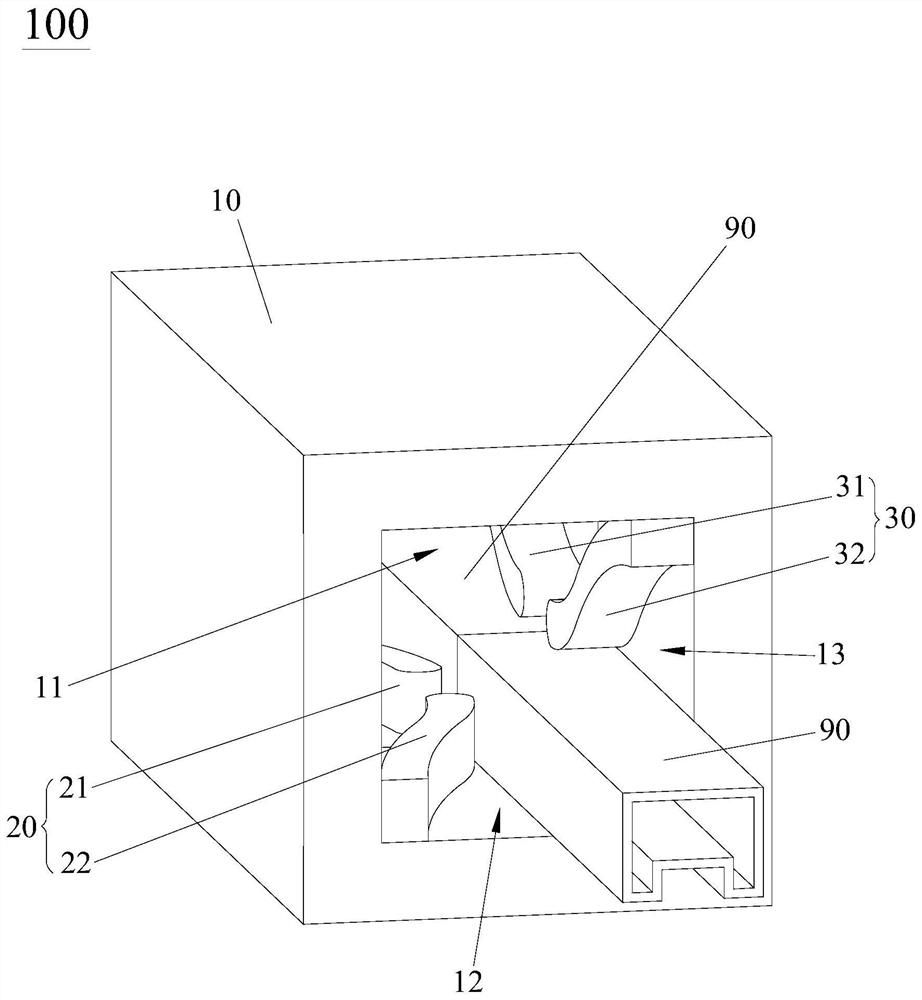

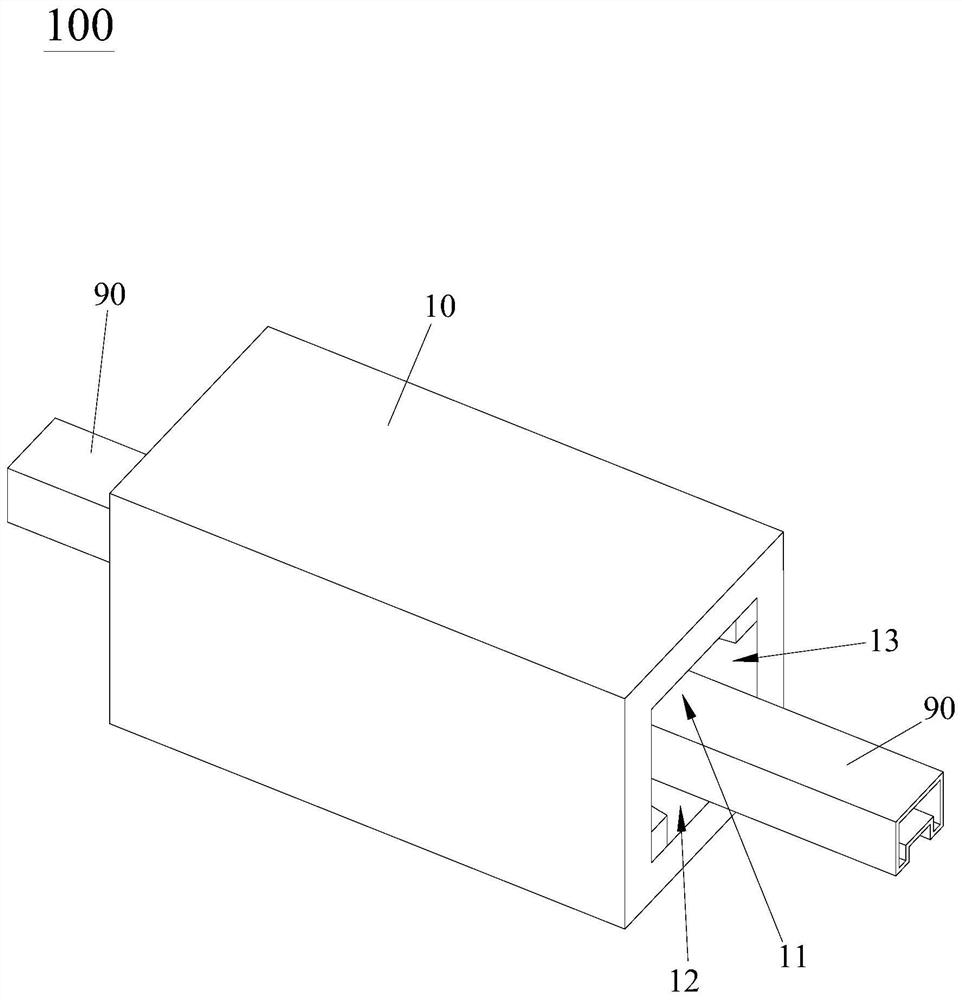

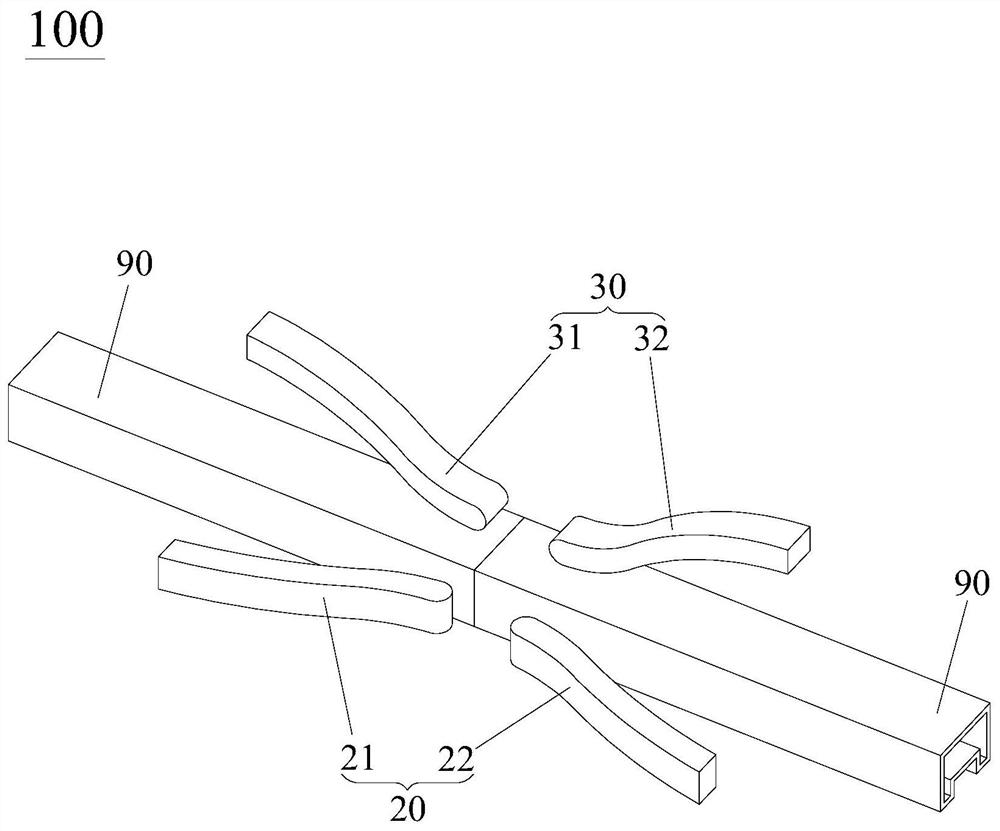

[0022] Such as Figure 1 to Figure 4 As shown, the chip gravity test inverted tube auxiliary tool 100 of the present invention includes a docking body 10 , a first pushing component 20 and a second pushing component 30 . The docking body 10 has a docking chamber 11 arranged in a through hole, the first push assembly 20 and the second push assembly 30 are installed in the docking chamber 11, and a feed pipe 90 is arranged in the docking chamber 11 and positioned against The positioning corner structure (not marked in the figure). The two material pipes 90 inserted into the docking chamber 11 are biased by the first pushing assembly 20 and the second pushing assembly 30 and are positioned on the positioning corner structure so that the two material pipes 90 are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com