A transport turnover device and its working method

A working method and technology for supporting the base, applied in the directions of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of easy spreading and unloading operations, inconvenient safety hazards, unstable mobile transportation status, etc., to prevent impurities The effect of falling, stable working state, and impact reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

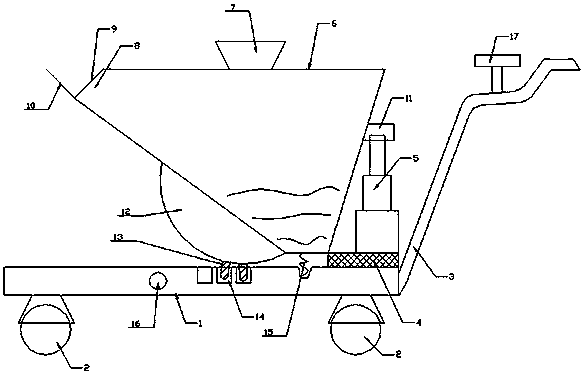

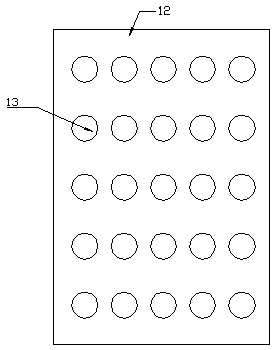

[0022] further as figure 1 and figure 2 As shown, another aspect of the present invention provides a working method of the transportation turnover device. The metal raw material liquid enters the storage box 6 from the feed port 7, and the pressure sensor 16 transmits the weight information of the raw material liquid to the monitoring component 17 in real time and It is displayed, and when the loaded safety weight is reached, it is reminded by the early warning horn of the monitoring component. When unloading, the cylinder 5 pushes the transmission plate 11 connected to the storage box 6 to tilt with the linkage support seat 12 as the fulcrum to complete the unloading operation.

[0023] Among them, in order to better realize the purpose of intelligent control and reduce manual input and management and control efficiency, on the one hand, the cylinder 5 of the transportation turnover device of the present invention can also be connected with the monitoring component 17, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com