Light-emitting chip grading method based on mixed programming and color coordinate rough grading

A light-emitting chip, color coordinate technology, applied in sorting and other directions, can solve the problems of the small number of color coordinate bins and the poor color consistency of the display screen, and achieve the effect of fewer bins and better project management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

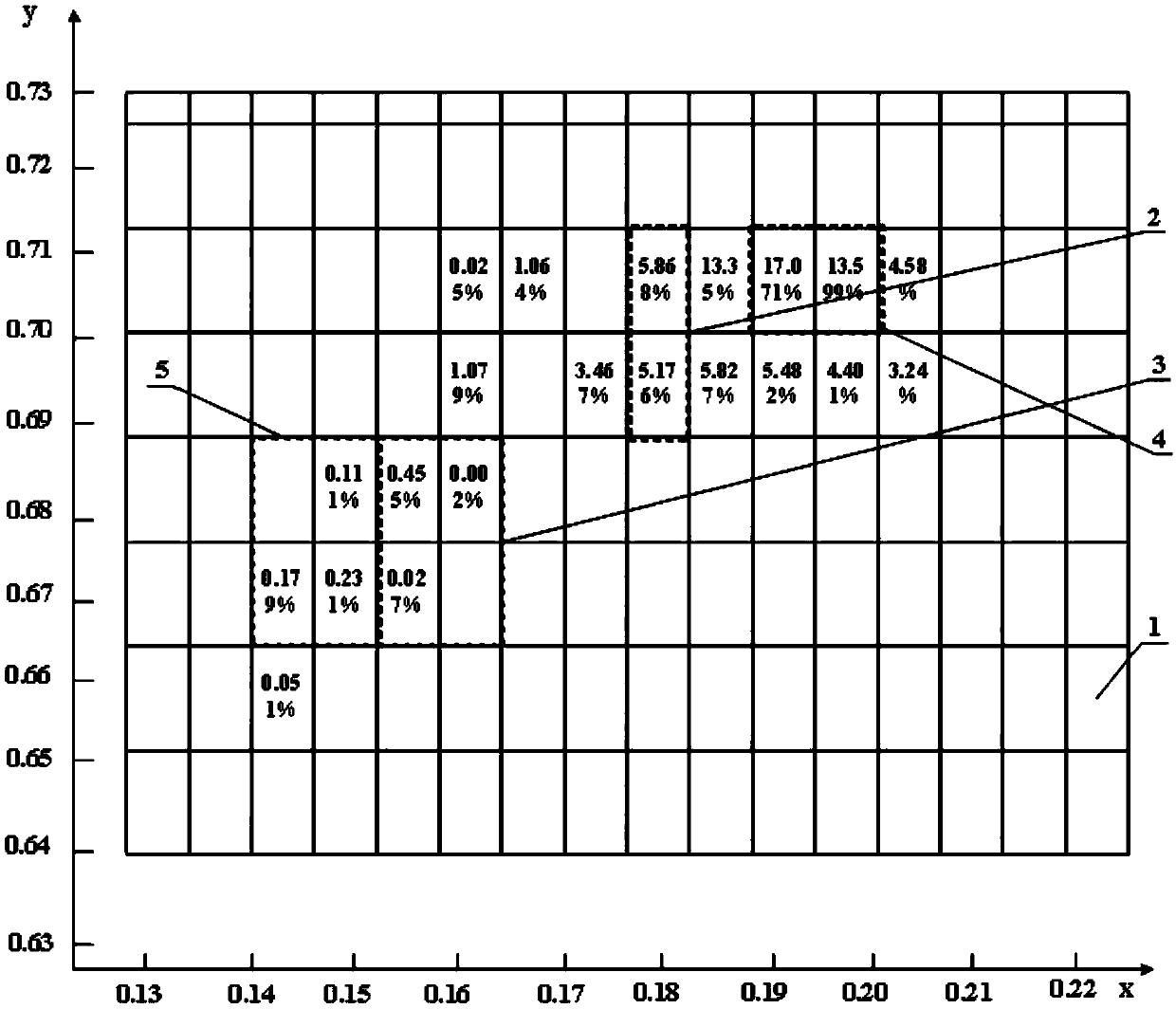

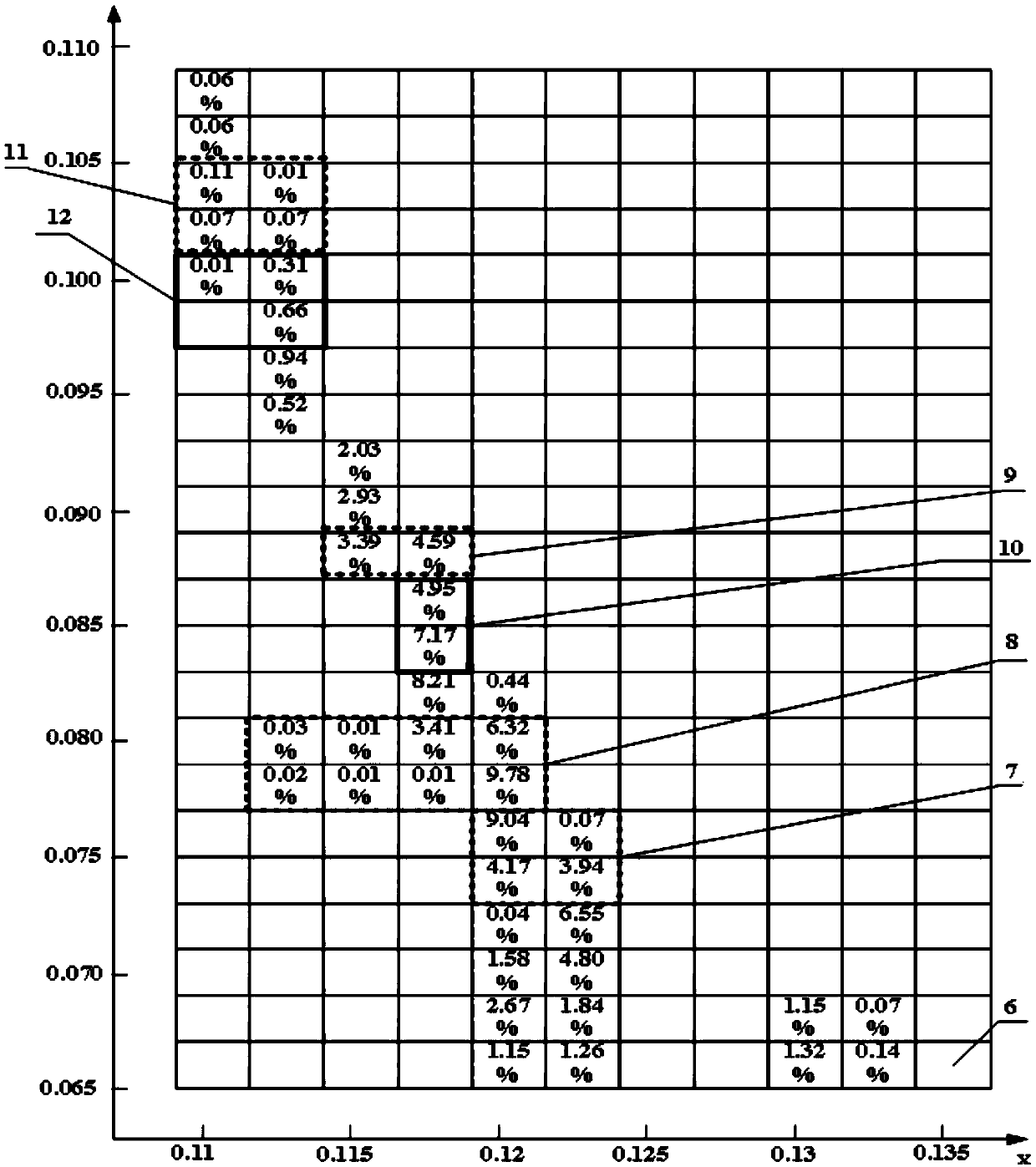

[0029] During the solid crystal operation, grab the light-emitting chips in the main file of each color standard and arrange them on a unit module. For example, during the solid crystal operation, red captures a light-emitting chip in a standard main file, and green captures figure 2 The light-emitting chip in the standard main file shown in the middle dotted line box 2, blue capture image 3 The light-emitting chip in the standard main file shown in the dotted line box 7. Modules with the same parameters are combined into one display screen. Although the color purity of the display screen produced in this way is slightly sacrificed, the light-emitting chips in the main files of each standard are fully mixed, there are no color blocks, and the number of gears is small, which is conducive to production management.

Embodiment 2

[0031] like figure 2 As shown, the scattered files represented by the dotted line box 3 and the scattered files represented by the dotted line box 5 are merged, and the light-emitting chips in the two scattered files are classified into one combined scattered file. During the solid crystal operation, red grabs a light-emitting chip in a standard main gear for use, and green grabs figure 2 The light-emitting chips in the merged file formed by the dotted line frame 3 and the dotted line frame 5 in the middle. blue grab image 3 The light-emitting chip in the standard main file shown in the thick solid line frame 10 in the middle. In this way, modules with the same parameters are combined into one display screen. Although the color purity of the display screen produced in this way is slightly sacrificed, it is fully mixed, has no color blocks, and has a small number of gears, which is conducive to production management.

Embodiment 3

[0033] like image 3 As shown, the dotted line box 11 and the thick solid line box 12 are combined into one combined scattered file. During the solid crystal operation, red grabs a light-emitting chip in a standard main gear for use, and green grabs figure 2 The light-emitting chip in the standard main file shown in the dotted line box 2. blue grab image 3 The dotted line box 11 and the thick solid line box 12 are combined into one combined light-emitting chip. In this way, modules with the same parameters are combined into one display screen. Although the color purity of the display screen produced in this way is slightly sacrificed, it is fully mixed, has no color blocks, and has a small number of gears, which is conducive to production management.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com