Construction plywood shaping device

A shaping device and plywood technology, which is applied in the field of board hot presses, can solve problems affecting the quality of processed wood boards, uneven heating, and affecting the production quality of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

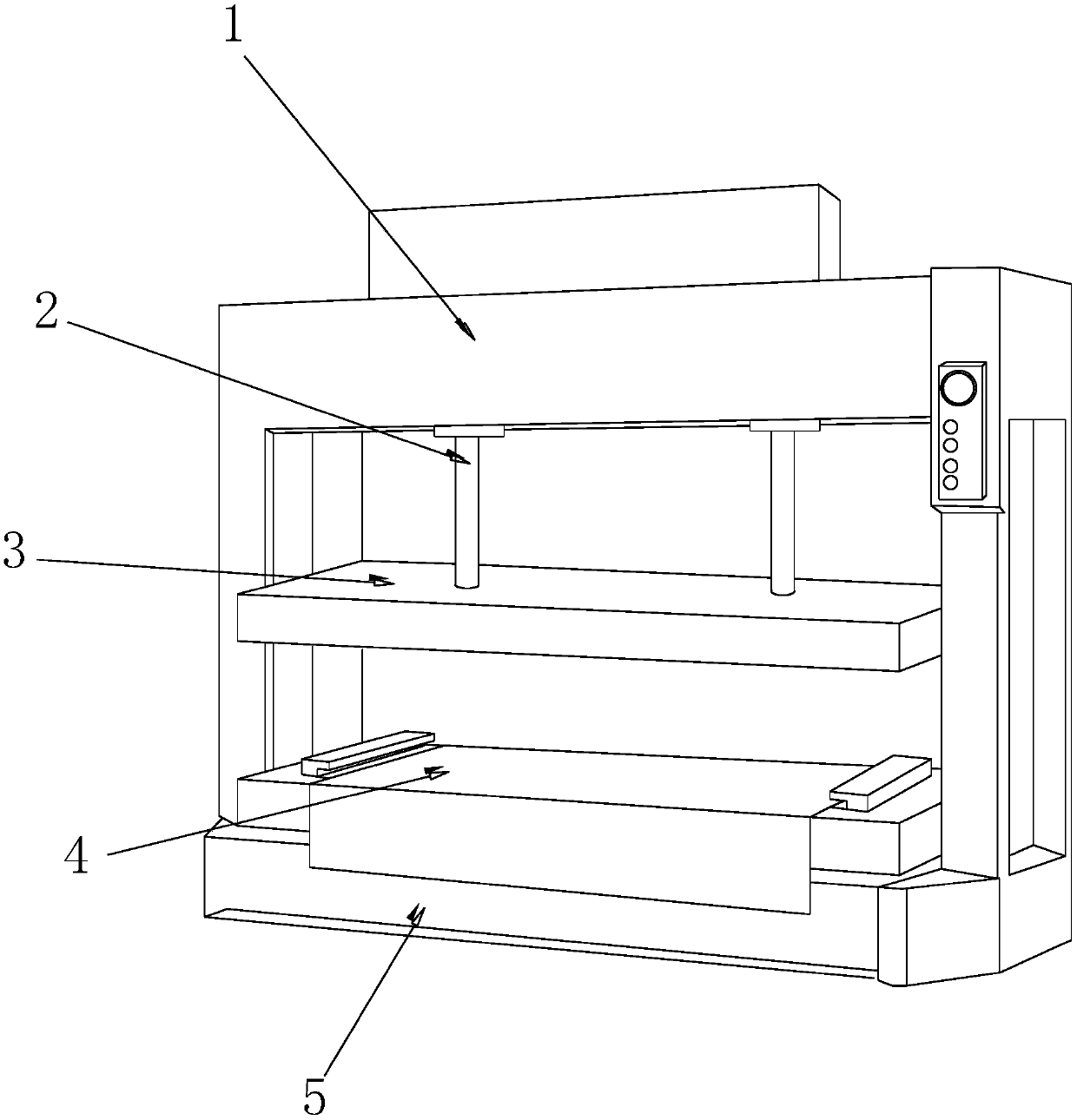

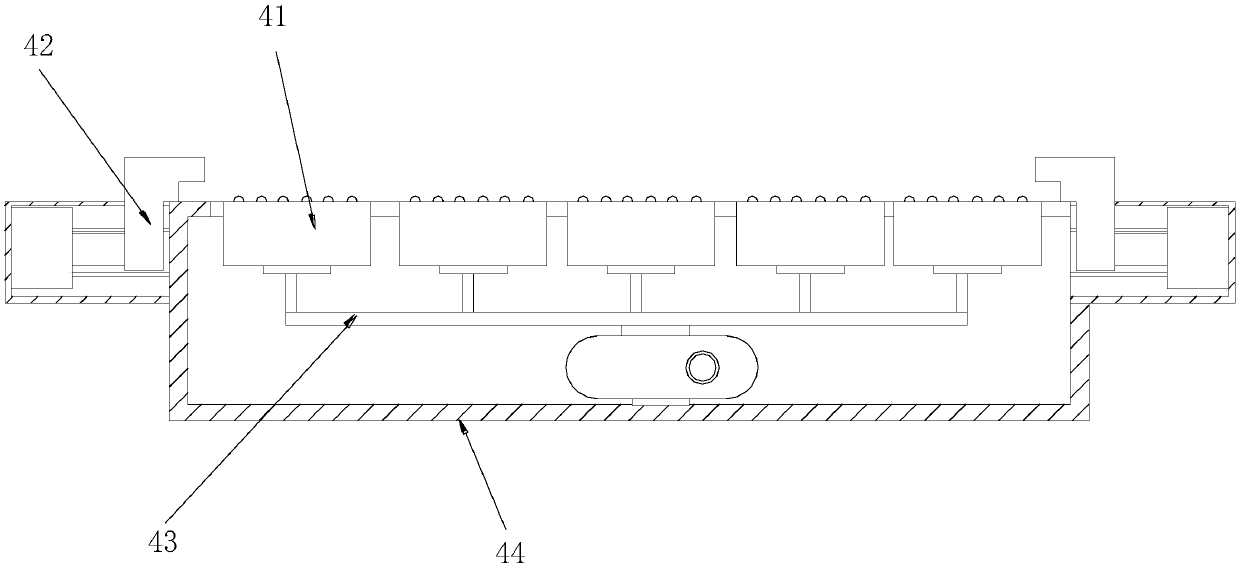

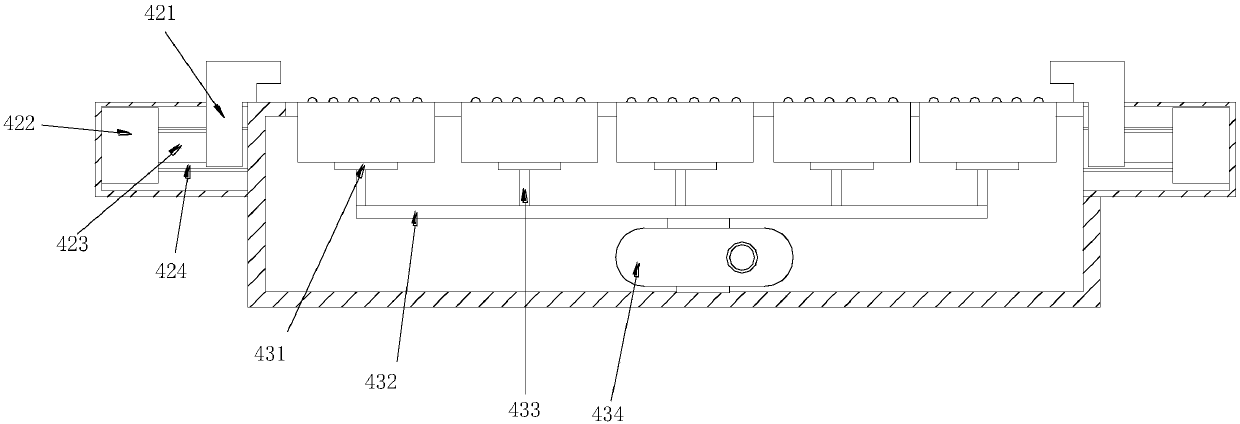

[0027] see Figure 1-Figure 6, the present invention provides a building plywood shaping device, its structure includes an upper top plate 1, a hot pressing push rod 2, a hot pressing plate 3, a placing table 4, and a base 5, and the bottom end of the upper top board 1 is vertically embedded with a hot pressing push rod 2 , the bottom end of the hot pressing push rod 2 is horizontally welded with a hot pressing plate 3, the hot pressing plate 3 is located directly above the placing table 4, the bottom end of the placing table 4 is welded to the top of the base 5, the The upper top plate 1 is located directly above the base 5, and the placement table 4 includes a concave-convex ejector mechanism 41, a clamping mechanism 42, an air delivery mechanism 43, and a casing 44. The top of the concave-convex ejector mechanism 41 is connected to the top of the casing 44 Welding, the end near the middle of the clamping mechanism 42 is welded to the left and right ends of the housing 44, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com