Bamboo spreading machine

A technology of bamboo unfolding machine and unfolding mechanism, which is applied in mechanical equipment, sugarcane machining, reed/straw processing, etc. It can solve the problems of easy cracking of bamboo and low yield of finished products, so that it is not easy to crack, has a high yield of finished products, and prevents re- curved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

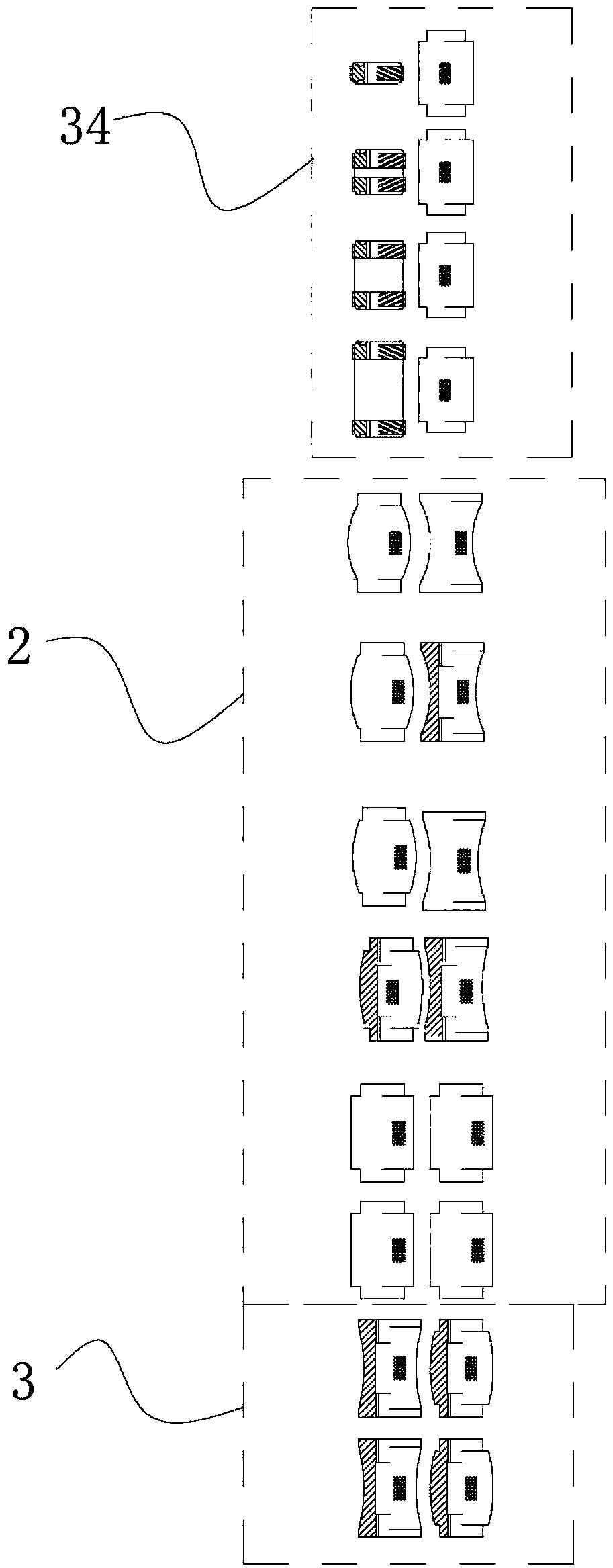

[0051] Such as Figure 7 As shown, in further detail, the scribing roller 35 is a plane scribing roller, and the number of groups of the plane scribing rollers in the scribing mechanism 34 is at least 2, and the distance between the scribing knives 36 increases step by step, and the scribing of adjacent scribing knives 36 The direction of the line is opposite.

Embodiment 2

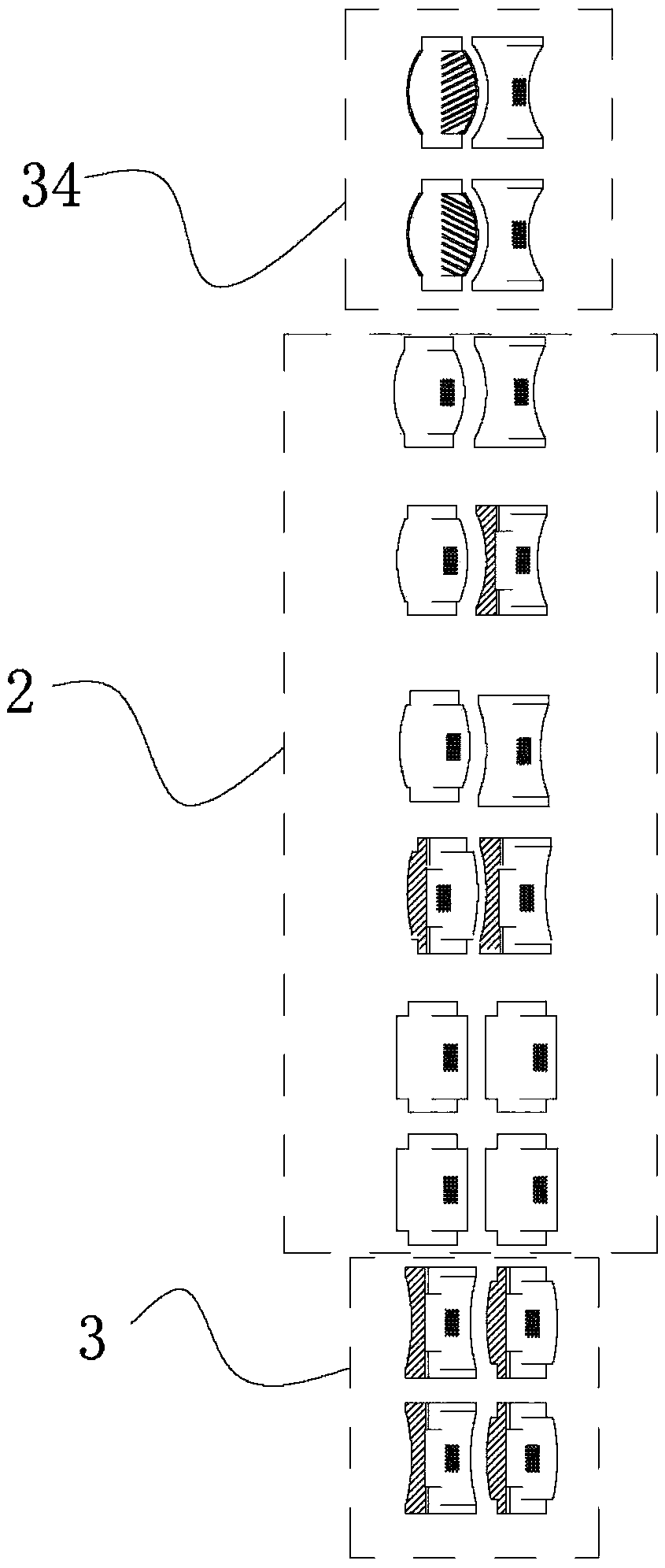

[0053] Such as Figure 8 As shown, in further detail, the scribing roller 35 is a curved scribing roller, and the number of groups of the scribing roller in the scribing mechanism 34 is at least one.

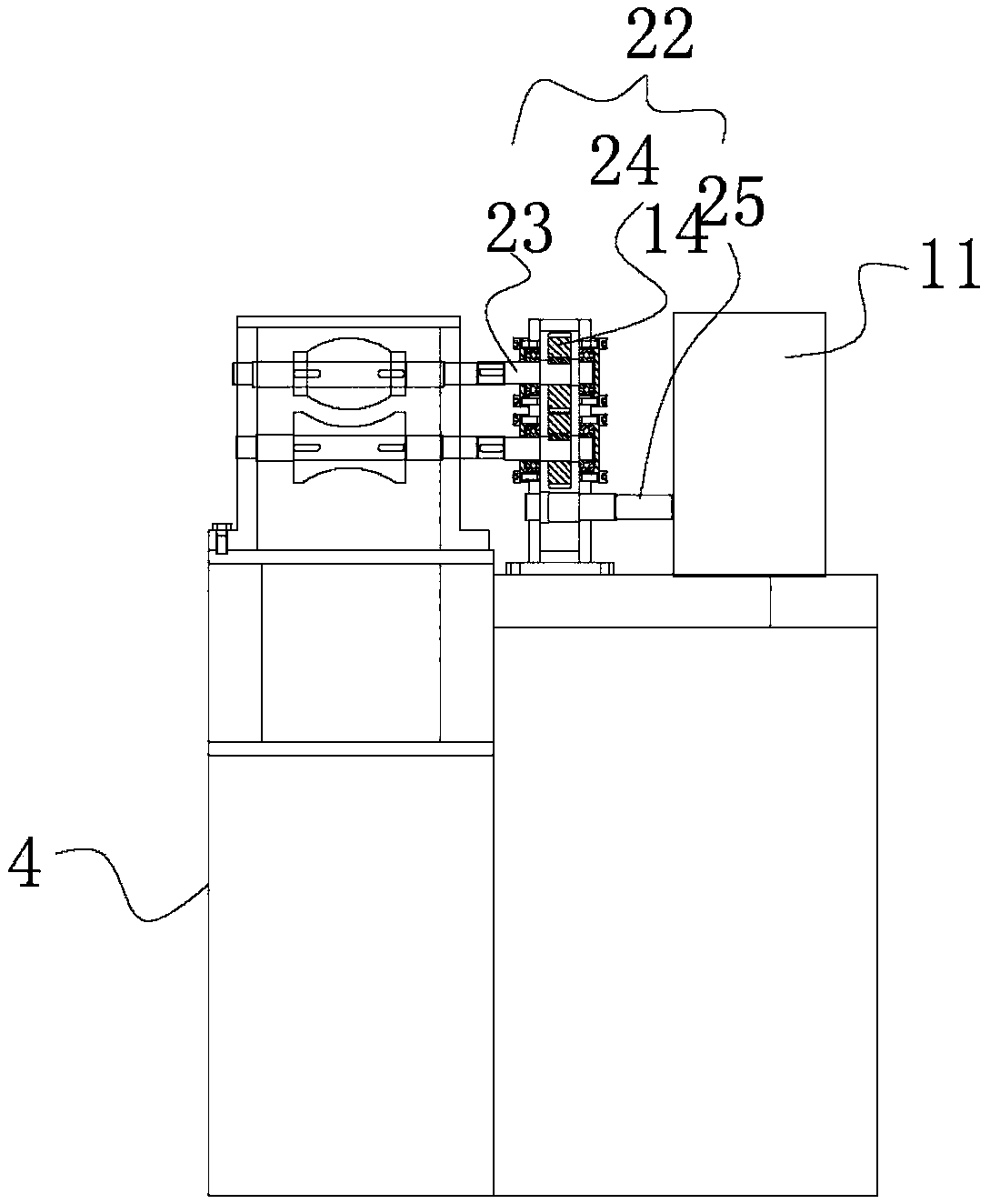

[0054] Although this paper uses a lot of planing mechanism 1, unfolding mechanism 2, reverse flattening roller 3, frame 4, arc surface shaping device 5, upper conveying roller 6, lower conveying roller 7, arc shaping gap 8, planer Yellow cutting mechanism 9, bamboo yellow cutting part 10, driving device 11, gradual flattening arc roller 12, flattening roller 13, upper pressing roller 14, lower pressing roller 15, arc-shaped unfolding gap 16, upper reverse pressing roller 17, lower pressing roller Reverse pressure roller 18, reverse sizing gap 19, planing green cutting mechanism 20, bamboo green cutting part 21, first transmission device 22, output shaft 23, gear 24, input shaft 25, second transmission device 26, rotating shaft 27, Terms such as belt 28, shaft sleeve 29, adjusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com