Composite inclined jacking mechanism of double-color headlamp matched mirror mould

A technology of inclined roof mechanism and headlight, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of inability to realize positioning rib forming and demoulding, and achieves simple structure, convenient operation and high market competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

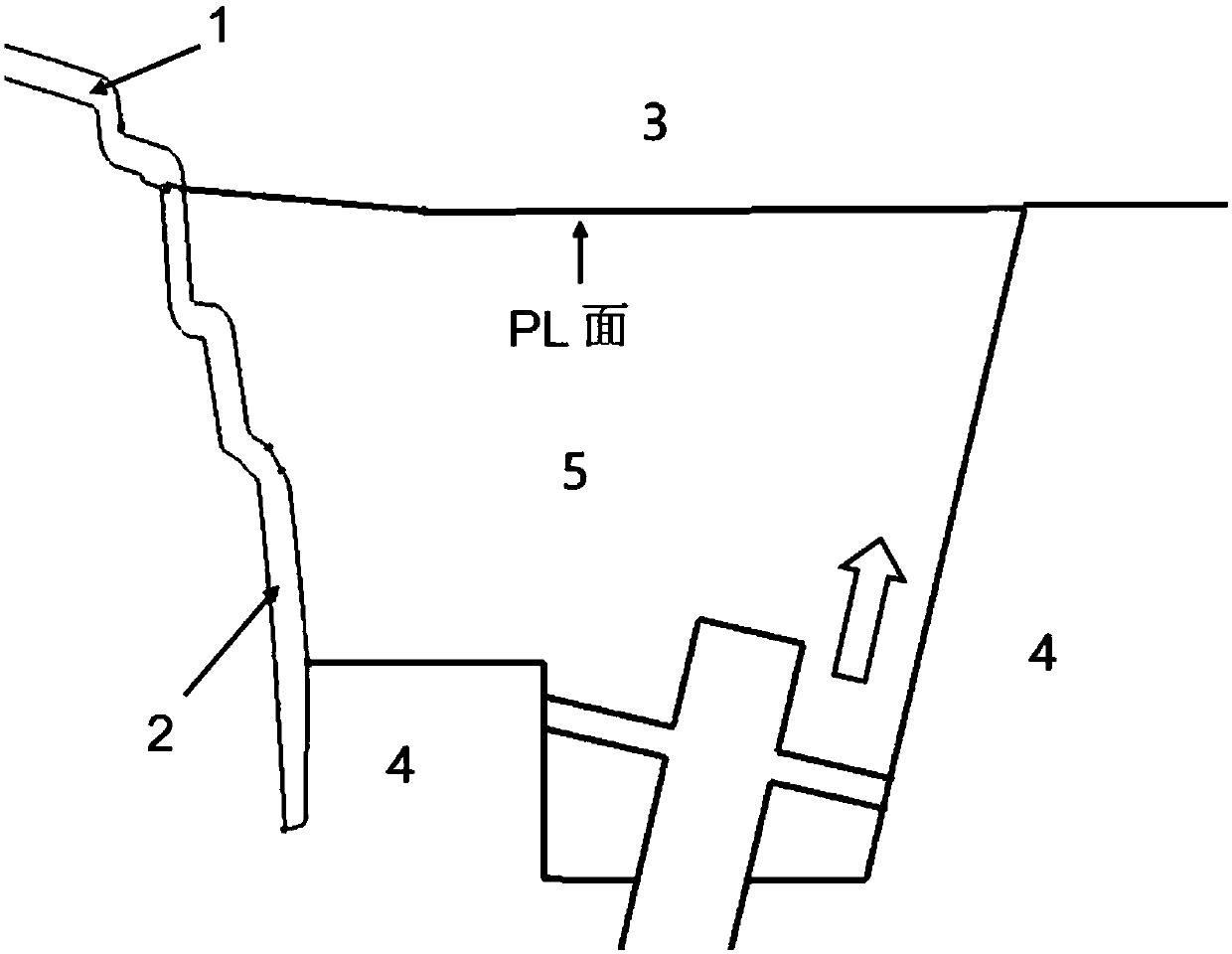

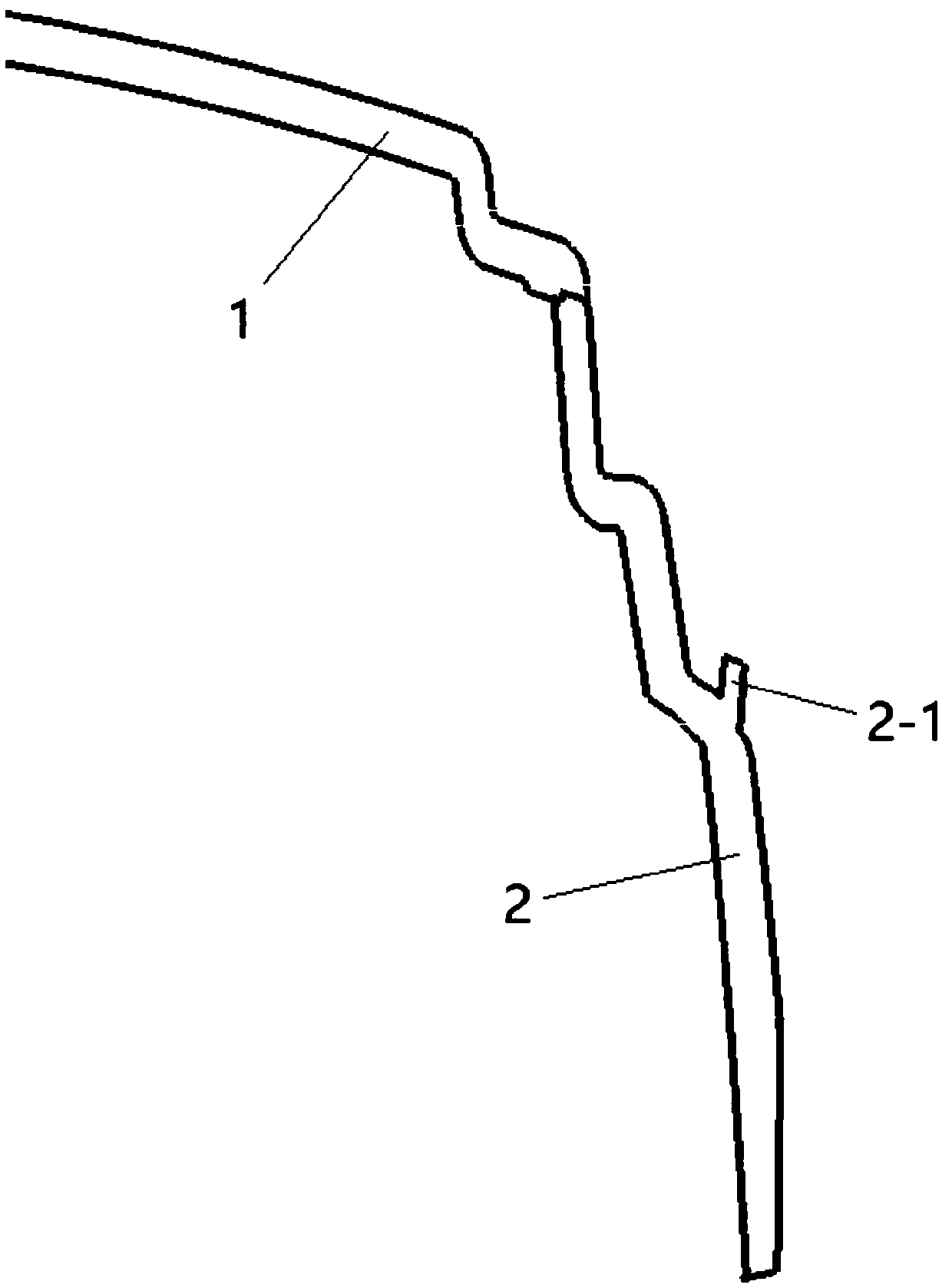

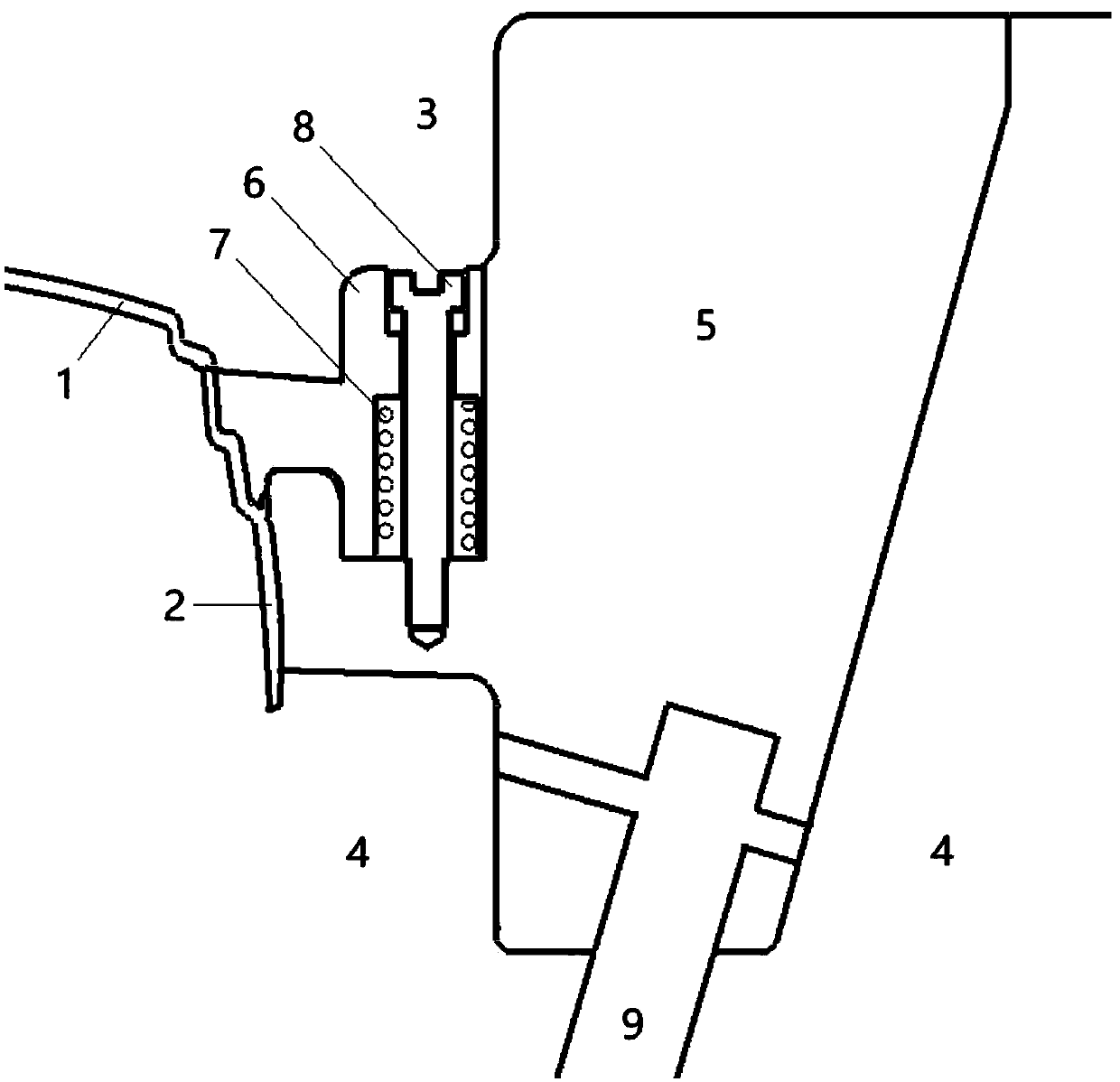

[0018] The invention discloses a composite inclined top mechanism of a two-color headlight light distribution mirror mold, such as image 3 , 4 As shown, it includes an inclined top 5 and an elastic block 6 , and the inclined top slides obliquely relative to the lower die 4 driven by the push rod 9 . A chute is provided on the slant top, and the spring block is installed in the chute and slidably fits with the slant top. The sliding direction of the bullet block relative to the inclined roof and the moving direction of the inclined roof (such as Figure 4 Arrows in ) form an included angle. The elastic block is provided with a lower groove with the opening facing downward, and the side of the elastic block close to the cavity is a forming surface, and the forming surface is provided with an oblique outward convex structure 6-1, and the forming surface together with the The convex structure surface and the same side of the sloping top are combined to be used for the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com