Organic silica gel PDMS based aeroengine bearing totally-enclosed packaging method

An aero-engine, silicone technology, used in packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of bearing damage, complex manufacturing process, high price, etc., to avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

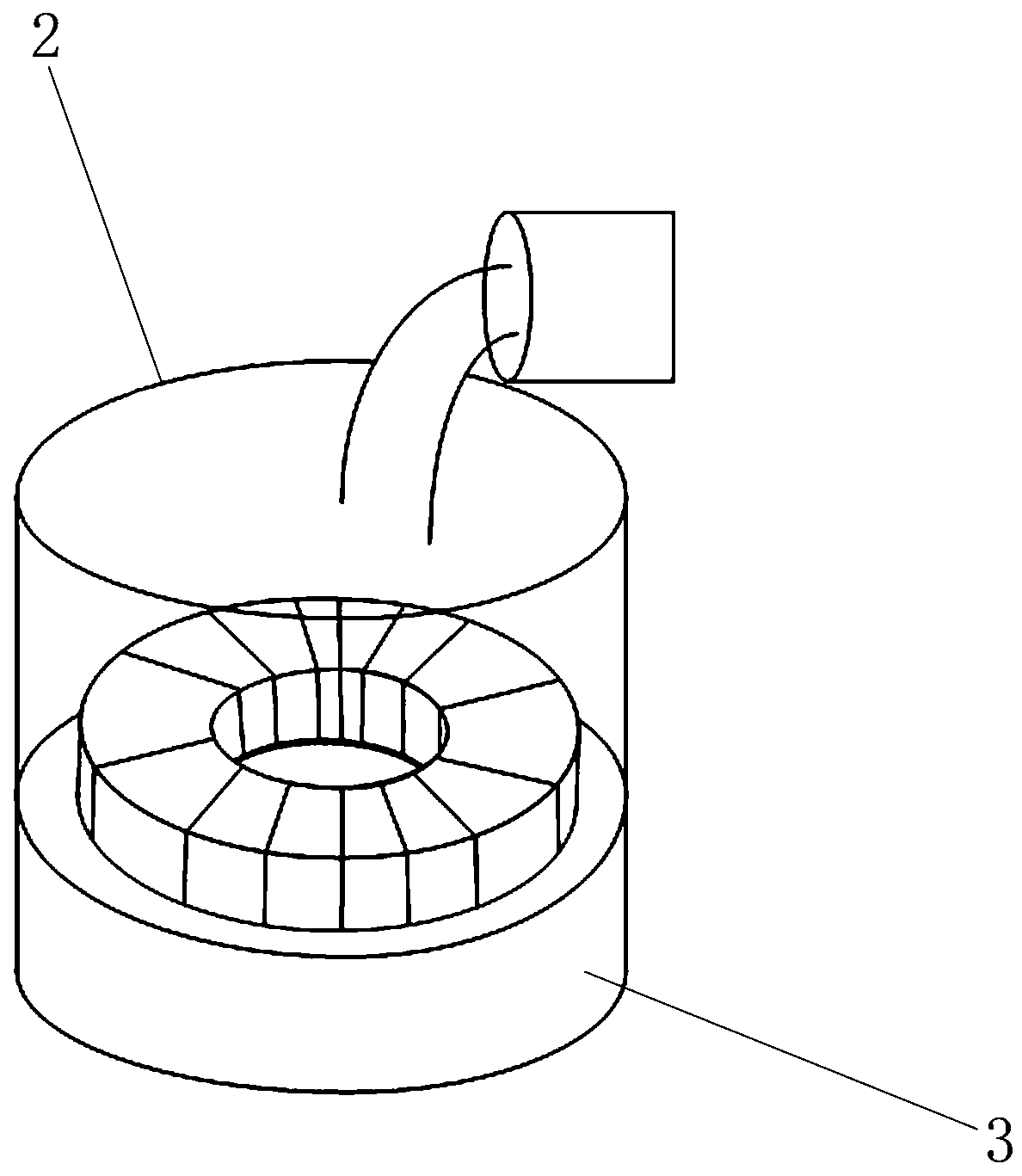

[0014] refer to Figure 1 to Figure 3 , an aero-engine bearing fully-enclosed packaging method based on organic silica gel PDMS, it comprises the following steps:

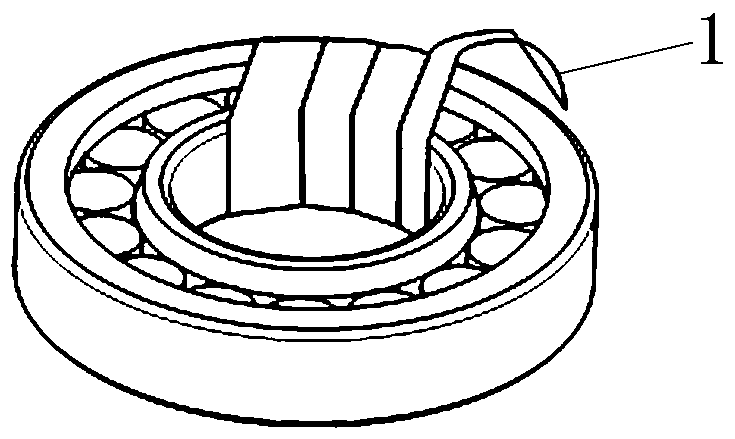

[0015] Step 1: Use a transparent strip of polyethylene film 1 to repeatedly pass through the center hole of the bearing to wrap the bearing completely, covering one-third of the previous circle when winding each circle; wrap more than two layers of polyethylene film 1, And the seams are sealed with high-permeability tape to ensure that the bearing does not come into contact with the liquid silicone PDMS in the next step;

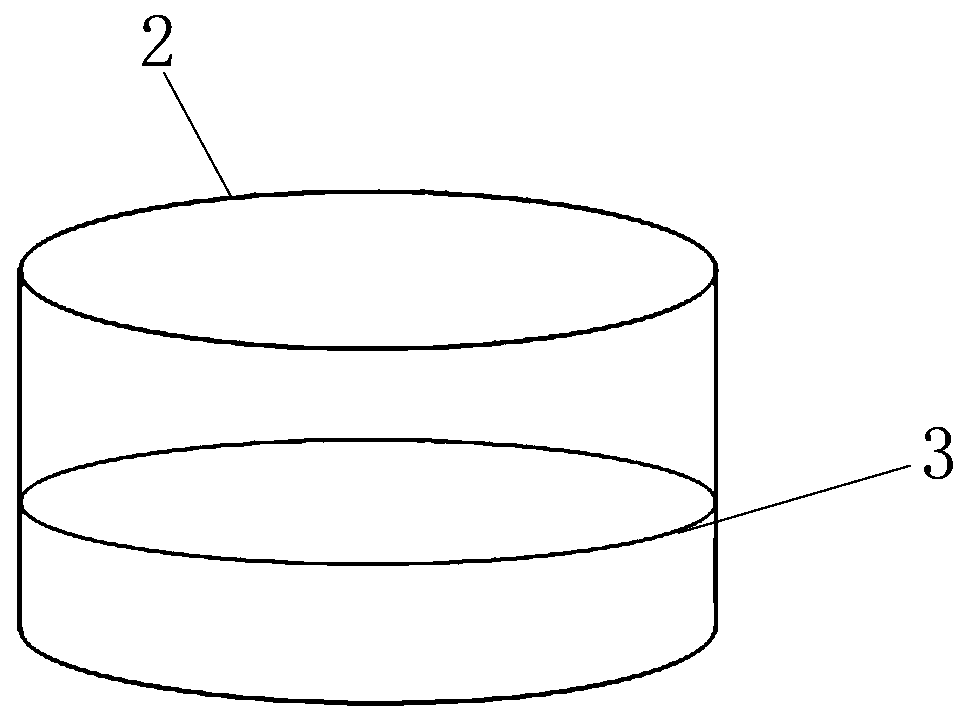

[0016] Step 2: Pour a mixed solution of liquid organic silicone PDMS and curing agent with a thickness of not less than 30 mm at the bottom of the mold 2, and wait to be cured to form the bottom cushion 3. PDMS is polydimethylsiloxane, which is a kind of organic silicone The mold 2 is a cylindrical container, the inner diameter of the mold 2 is more than ten millimeters larger than the outer dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com