Transparent beta-silicon nitride ceramics and preparation method thereof

A silicon nitride ceramic and transparent technology, which is applied in the field of transparent β-silicon nitride ceramics and its preparation, can solve the problems of reduced light transmittance, difficulty in preparing transparent β-silicon nitride ceramics, etc., and achieve good thermal shock resistance , excellent mechanical properties, high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] to Si 3 N 4 powder and MgSiN 2 Powder is the raw material, and the weight ratio of the two is 100:4. After the raw materials are evenly mixed, they are firstly dry-pressed and then put into a graphite mold. The sintering time is 50 hours; after the sintering, the sample is cooled to room temperature with the furnace, and a transparent β-silicon nitride ceramic is obtained.

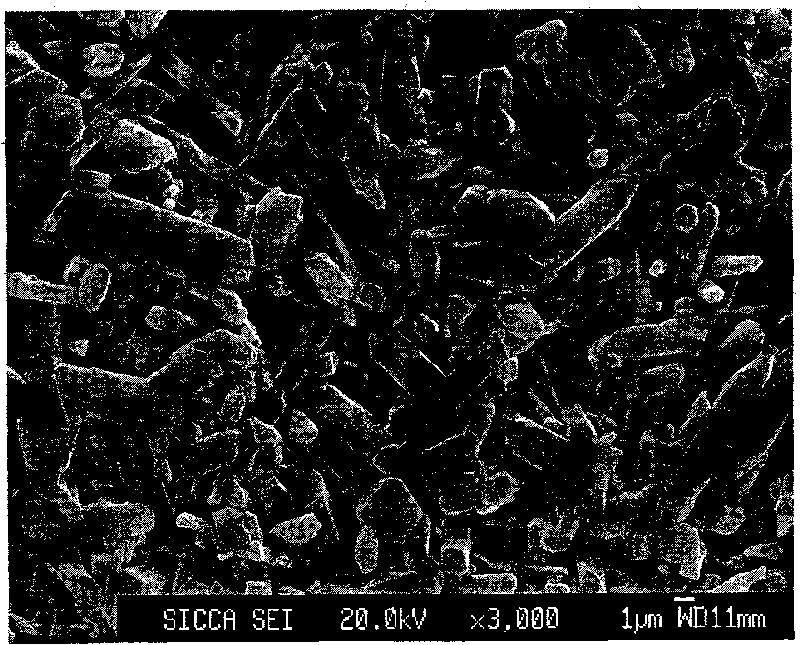

[0017] figure 1 The physical photos of the transparent β-silicon nitride ceramics with an unpolished surface and a thickness of about 1 mm obtained in this example are given; as identified by XRD, the transparent ceramics prepared by the above process have a single crystal phase of β-Si 3 N 4 phase; microstructural analysis of this sample showed that it was composed of long rod-shaped grains, such as figure 2 shown.

Embodiment 2

[0019] to Si 3 N 4 Powder, MgSiN 2 Powder and Y 2 o 3 Powder is the raw material, and its weight ratio is 100:6.7:0.5. After the raw materials are evenly mixed, they are put into graphite molds, and the mechanical pressure is 60MPa, the nitrogen pressure is 2.0MPa, the temperature is 2100°C, and the holding time is 30 hours. After sintering, the sample was cooled to room temperature with the furnace to obtain transparent β-silicon nitride ceramics.

Embodiment 3

[0021] to Si 3 N 4 Powder, MgSiN 2 powder, CaO powder and Y 2 o 3 Powder is the raw material, and its weight ratio is 100:1.9:0.2:0.1. After the raw materials are evenly mixed, they are put into graphite molds, and the mechanical pressure is 70MPa, the nitrogen pressure is 4.5MPa, the temperature is 2250°C, and the holding time is 25 hours. After sintering, the sample was cooled to room temperature with the furnace to obtain transparent β-silicon nitride ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com