An integrated ic tape packaging feeding and discharging system

An integrated, material in and out technology, applied in the direction of packaging, etc., can solve the problems of not being compatible with hanging equipment, occupying space, increasing material control and management costs, etc., to reduce material management and control costs, convenient operation, and saving The effect of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

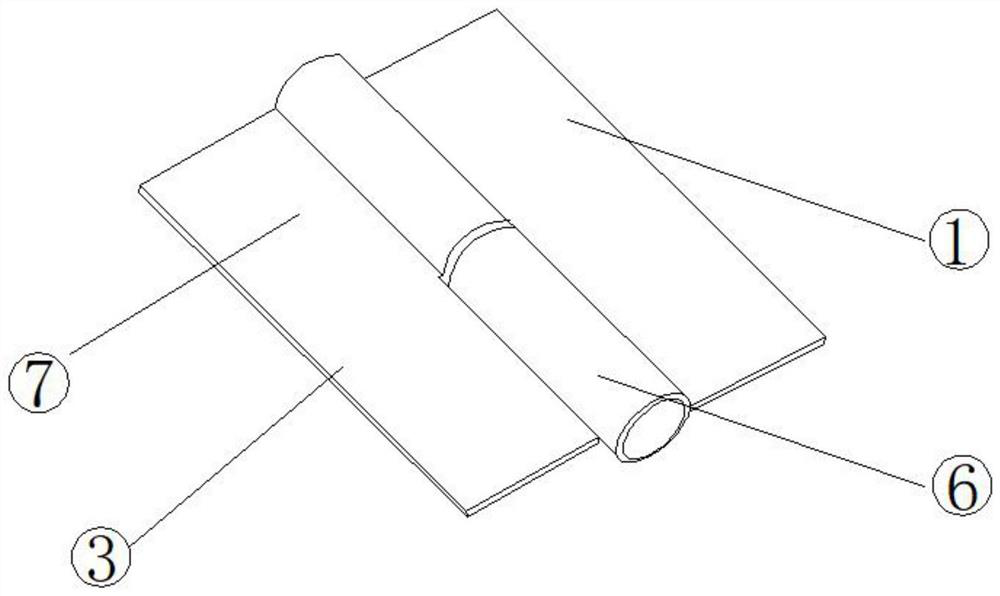

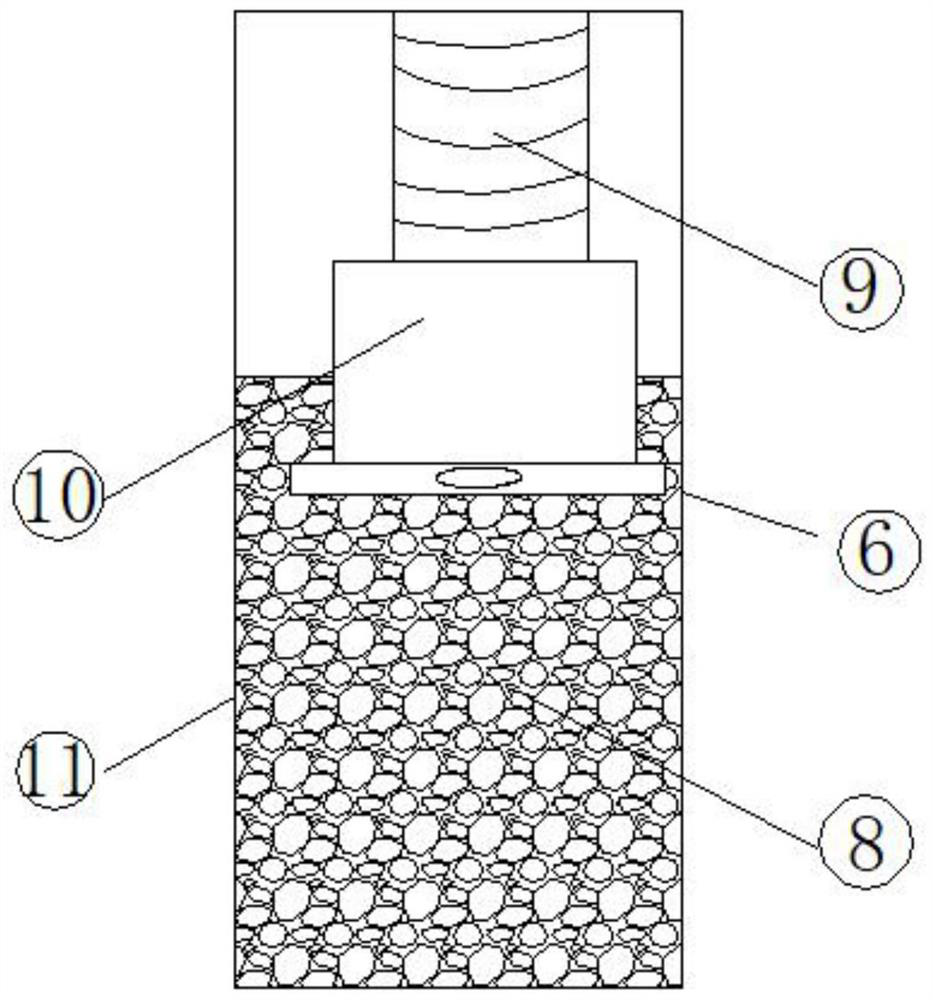

[0042] Such as Figure 1-4 As shown, a kind of integrated IC tape packaging feeding and discharging system includes a tape-out track 1, a tape-in track 2, a tape-in drive 4 and a tape-out drive 5, and the tape-out track 1 and the tape-in track 2 are fixedly installed In the middle position of the device, the front end of the tape-out track 1 is fixedly connected with the tape-out drive 5 , and the rear end of the tape-in track 2 is fixedly connected with the tape-in drive 4 .

[0043] A feed material belt is fixedly installed on the drive shafts at both ends of the belt-feeding track 2 , and a discharge material belt is fixedly installed on the drive shafts at both ends of the belt-out track 1 .

[0044] The concrete steps of described implementation are as follows:

[0045] A. The feed material belt enters from the rear to the front through the belt feed track 2, and the feed belt drives the 4 gears to rotate forward to drive the material belt to feed forward;

[...

Embodiment 2

[0048] Such as Figure 1-4 As shown, a kind of integrated IC braiding and packaging feeding and unloading system includes a tape-out track 1, a tape-in track 2, a width-adjusting auxiliary rail 3, a tape-in drive 4 and a tape-out drive 5, and the tape-out track 1 and The belt-in track 2 is fixedly installed in the middle of the device, and one side of the belt-out track 1 and the belt-in track 2 is fixedly installed with a width-adjustable auxiliary rail 3, and the front end of the belt-out track 1 is fixedly connected with the belt-out drive 5 , the rear end of the tape feed track 2 is fixedly connected with the tape feed drive 4 .

[0049] A feed material belt is fixedly installed on the drive shafts at both ends of the belt-feeding track 2 , and a discharge material belt is fixedly installed on the drive shafts at both ends of the belt-out track 1 .

[0050]The width-adjusting auxiliary rail 3 includes a width-adjusting plate 7 and a hydraulic connection shaft 6. The w...

Embodiment 3

[0062] Such as Figure 1-4 As shown, a kind of integrated IC braiding and packaging feeding and unloading system includes a tape-out track 1, a tape-in track 2, a width-adjusting auxiliary rail 3, a tape-in drive 4 and a tape-out drive 5, and the tape-out track 1 and The belt-in track 2 is fixedly installed in the middle of the device, and one side of the belt-out track 1 and the belt-in track 2 is fixedly installed with a width-adjustable auxiliary rail 3, and the front end of the belt-out track 1 is fixedly connected with the belt-out drive 5 , the rear end of the tape feed track 2 is fixedly connected with the tape feed drive 4 .

[0063] A feed material belt is fixedly installed on the drive shafts at both ends of the belt-feeding track 2 , and a discharge material belt is fixedly installed on the drive shafts at both ends of the belt-out track 1 .

[0064] The width-adjusting auxiliary rail 3 includes a width-adjusting plate 7 and a hydraulic connection shaft 6. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com