Toilet structure composed of riser embedded parts and its construction method

A technology of toilet structure and pre-embedded parts, which is applied in the direction of indoor sanitary pipe installations, water supply installations, drainage structures, etc. The effect of simplicity, increased stability, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

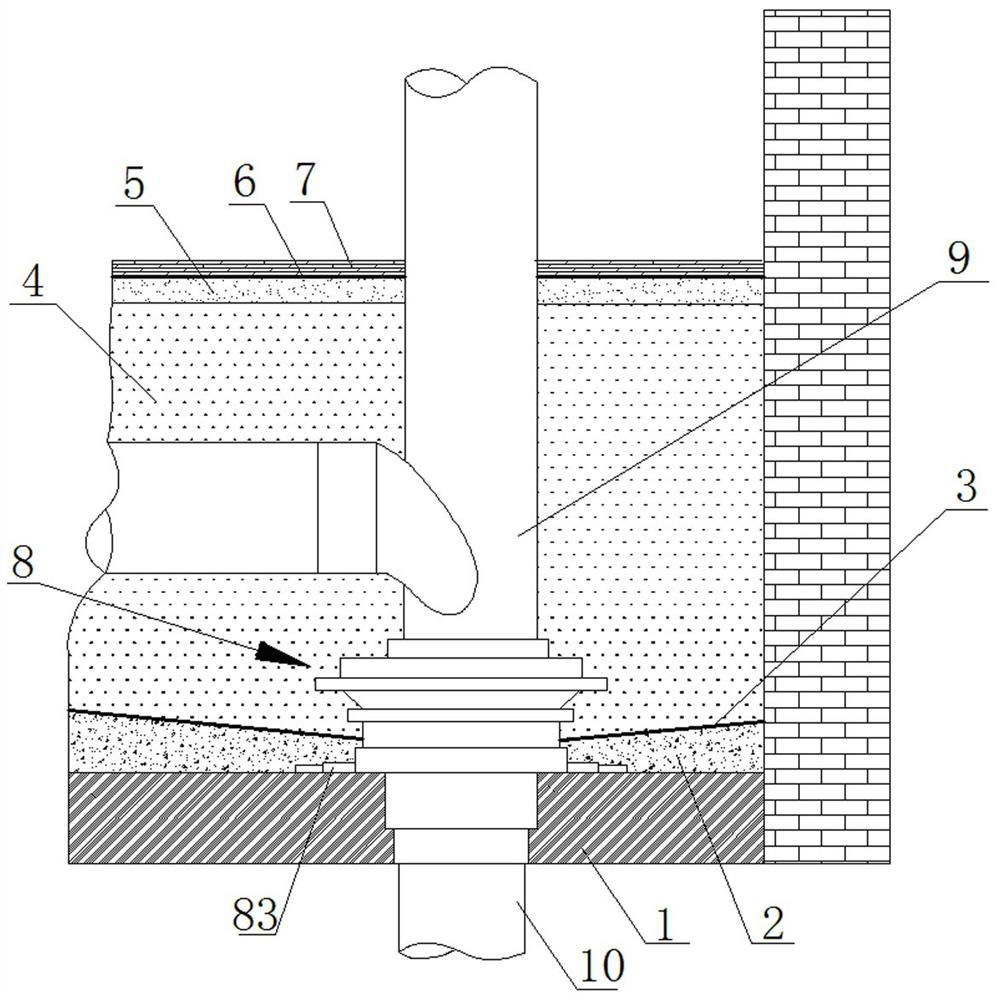

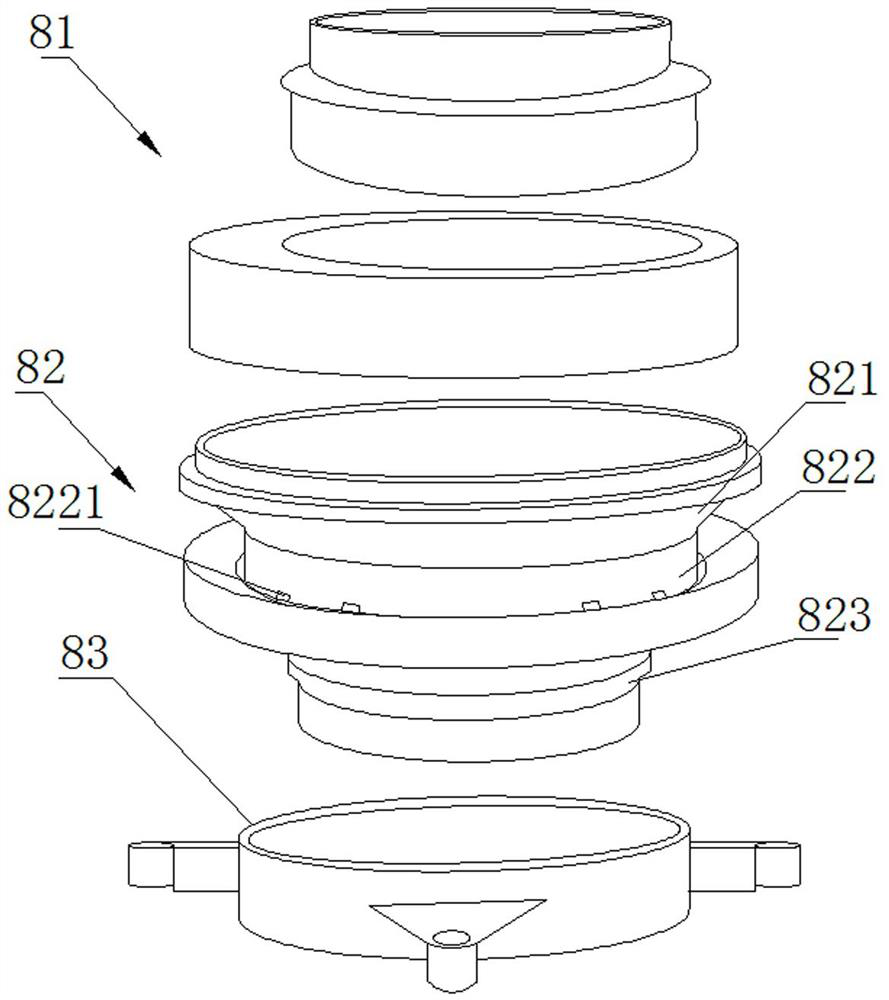

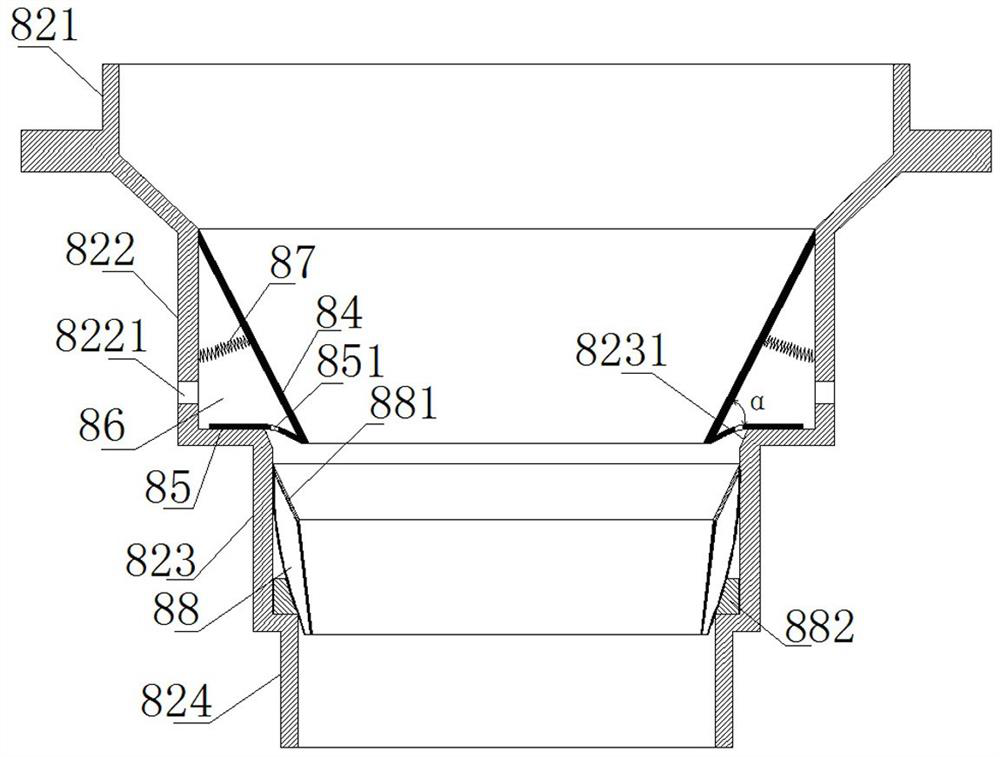

[0040] Such as Figures 1 to 4 As shown, the bathroom structure composed of the riser embedded parts device includes the water drain 8, the upper riser 9, the lower riser 10, and the cast-in-place floor 1, the lower leveling layer 2, and the lower waterproof Layer 3, filling layer 4, upper leveling layer 5, upper waterproof layer 6, and decorative surface layer 7; the lower part of the accumulated water drain 8 is pre-buried in the cast-in-situ floor 1; the upper riser 9 and the accumulated water discharge The upper end of the device 8 is plugged; the lower standpipe 10 is plugged with the lower end of the accumulated water discharger 8; the accumulated water discharger 8 includes an eccentric adjustment member 81 and a water passing body 82 sleeved from top to bottom; the upper The standpipe 9 is plugged on the eccentric adjustment part 81;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com