Prefabricated wall panel of house

A technology for prefabricating wall panels and wall panels, which is applied to walls, building components, thermal insulation, etc., can solve the problems of not being able to play fire, not setting regulators, and not being able to secure the body of the wall panels, so as to achieve safe and convenient use and enhance load-bearing capacity. , the effect of scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

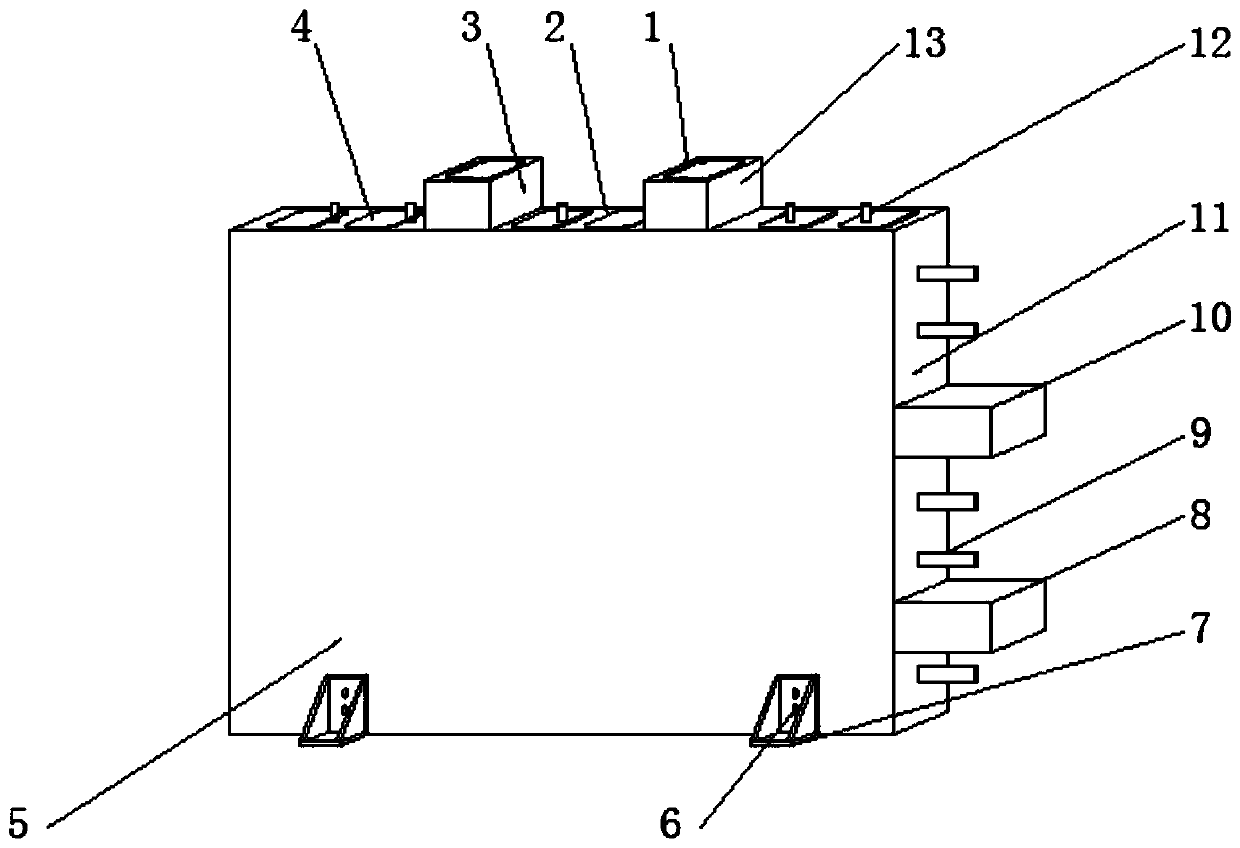

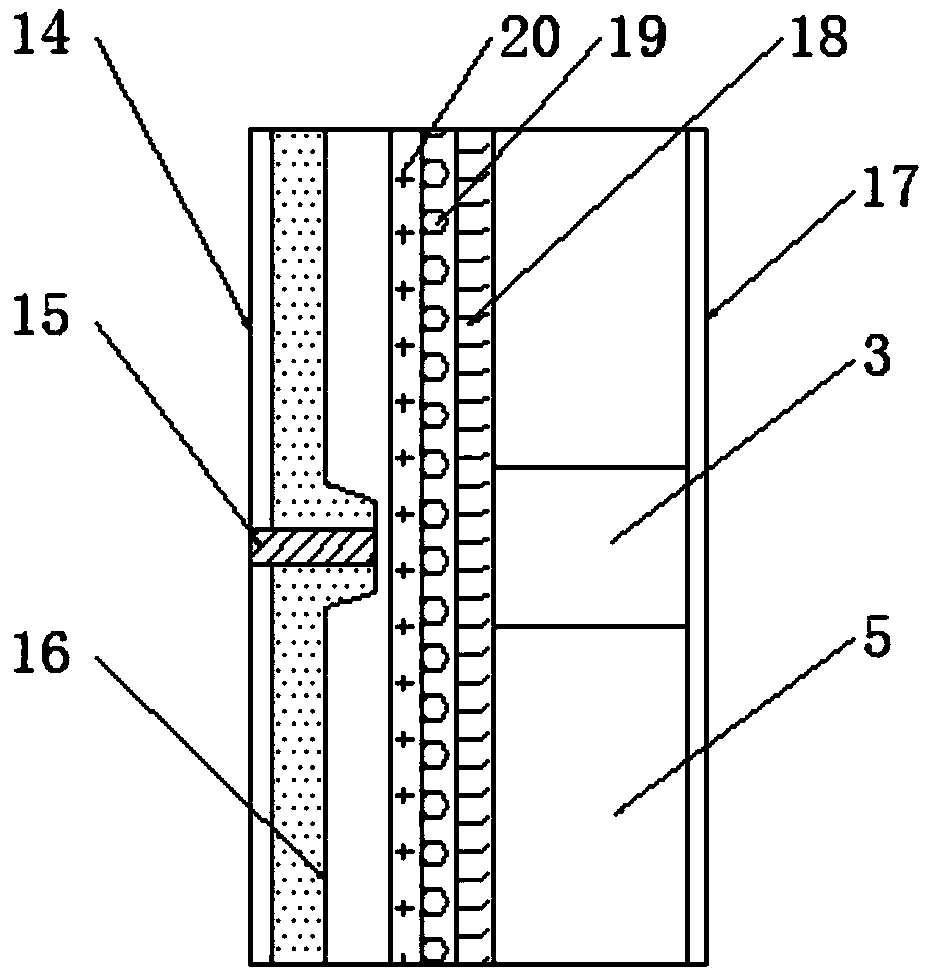

[0017] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a prefabricated wall panel for a house, including a vertical beam hoop 1, a wall hoop 2, a first load-bearing vertical beam 3, a decorative upper wall panel 4, and a wall panel body 5 , fixing bolt holes 6, adjuster 7, first reinforcement rib beam 8, perforated steel bar 9, second reinforcement rib beam 10, decorative side panel 11, beard rib 12, second load-bearing vertical beam 13, interior decoration surface layer 14, Sealing paste 15, external hanging board 16, exterior finish layer 17, sound insulation board 18, rock wool board 19 and insulation board 20, the front surface of wallboard body 5 is provided with exterior finish layer 17, and the top of wallboard body 5 is provided with There is a decorative upper wallboard 4, the interior of the decorative upper wallboard 4 is provided with wall hoops 2, and the upper surface of the decorative upper wallboard 4 is embedded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com