Multifunctional friction wear testing device

A friction and wear test, multi-functional technology, used in measuring devices, testing wear resistance, instruments, etc., can solve the problems of waste of equipment resources, increased experimental costs, complex working conditions, etc., to facilitate the overall installation and replacement and disassembly, reduce The overall cost of the equipment, the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

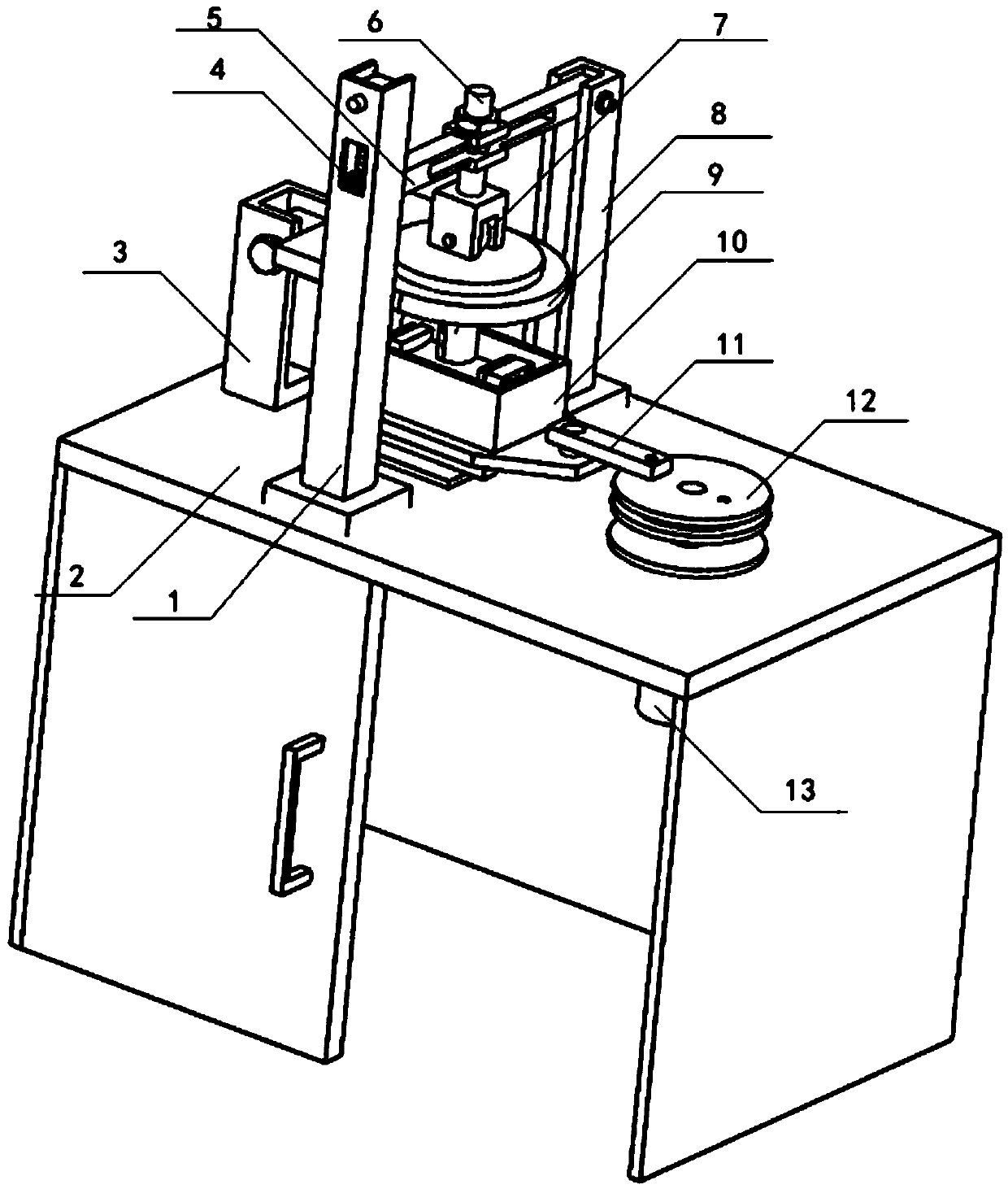

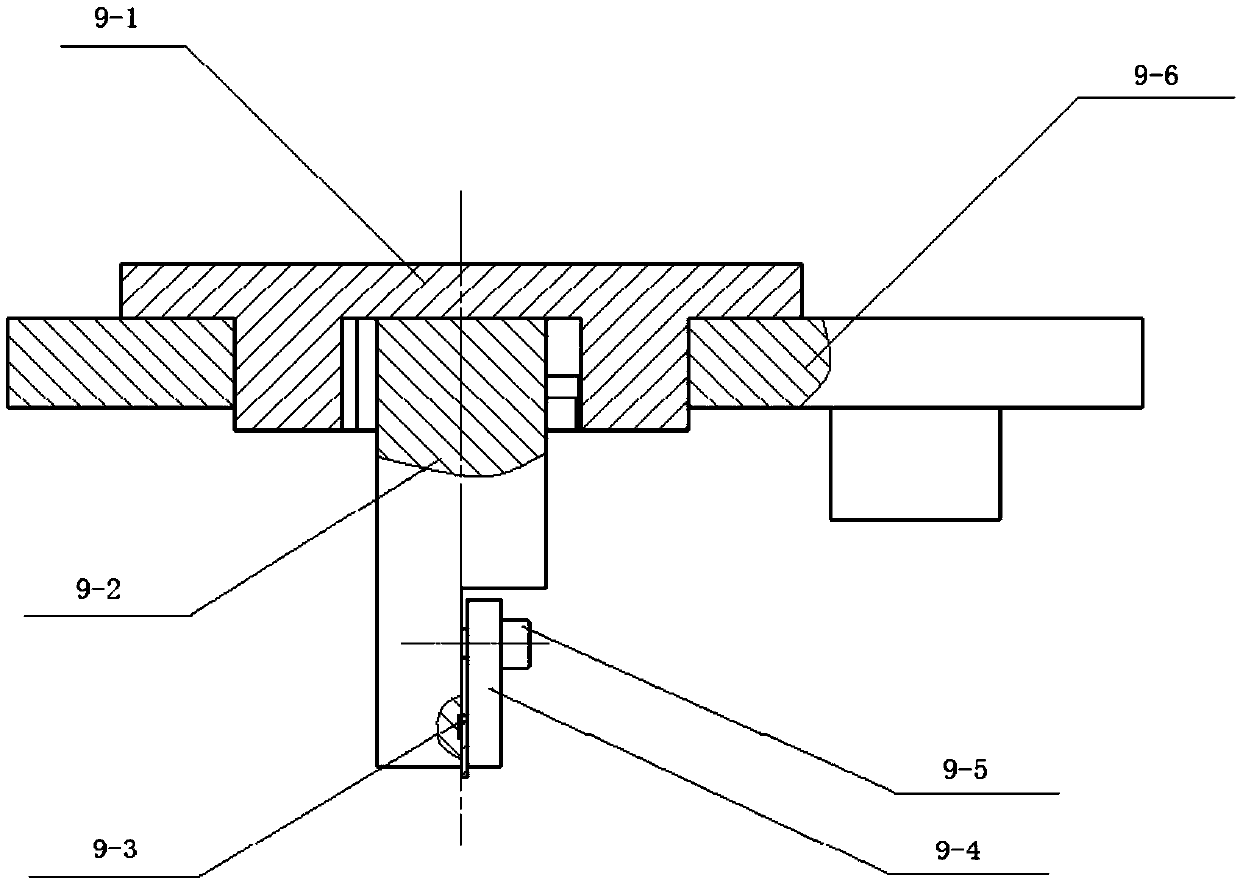

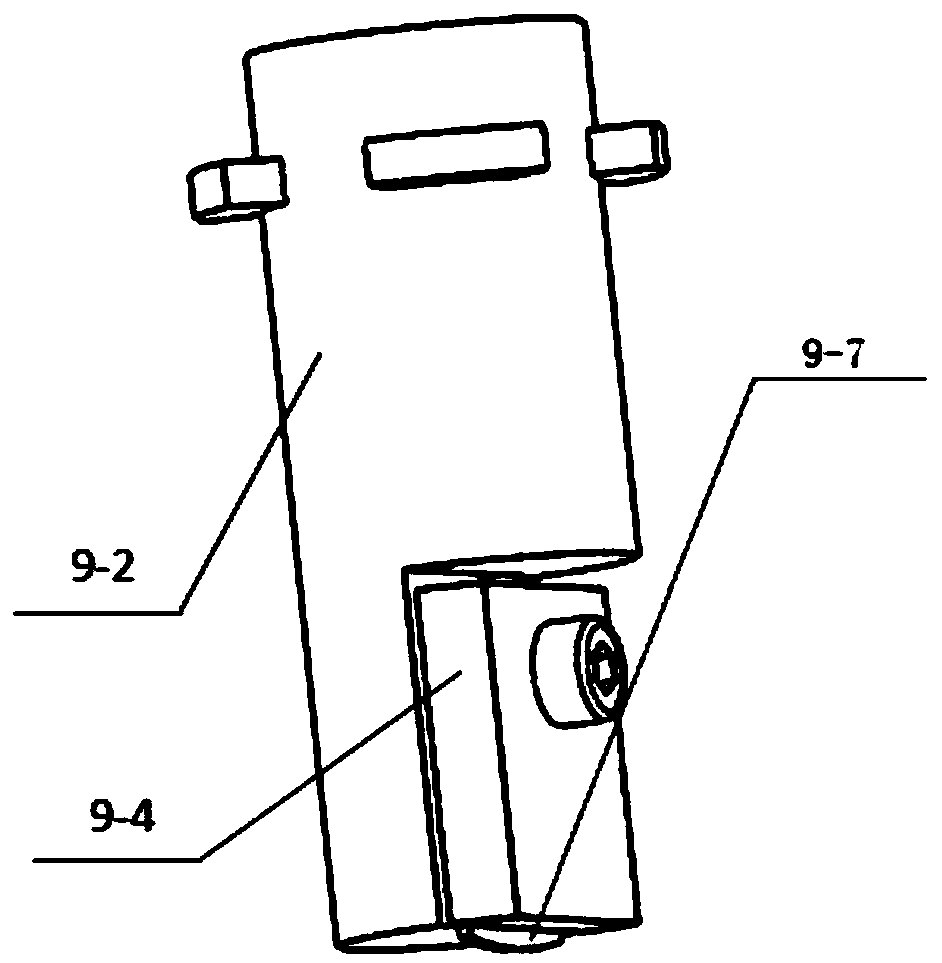

[0048] A multifunctional friction and wear test device of this embodiment includes a workbench 2, a variable loading assembly 4, an upper friction pair assembly 9, a reciprocating lower friction pair assembly 10, a pin-disk type lower friction pair assembly 14, and a crank disc 12 , spindle motor 13; front side, rear side and left side of workbench 2 are provided with front column 1, rear column 8 and side column 3 respectively, and crossbeam 5 is framed between front column 1 and rear column 8; Install on front column 1 There is a variable loading assembly 4, and one end of the rear column 8 and the crossbeam 5 is hinged and fixed by a pin, and the other end of the crossbeam 5 is connected to the variable loading assembly 4; the middle part of the crossbeam 5 is fixed with a loading rod 6, and the bottom of the loading rod 6 is connected with a roller 7. There is an upper friction pair assembly 9 under the roller 7; the upper friction pair assembly 9 is fixed on the side colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com