Sleeve grouting quality inspection device

A detection device and sleeve grouting technology, applied in the direction of material resistance, etc., can solve the problems of high cost of induction devices, inability to popularize on-site, and complicated test equipment, so as to reduce the influence of differences in construction conditions, reliable detection results, and improve sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

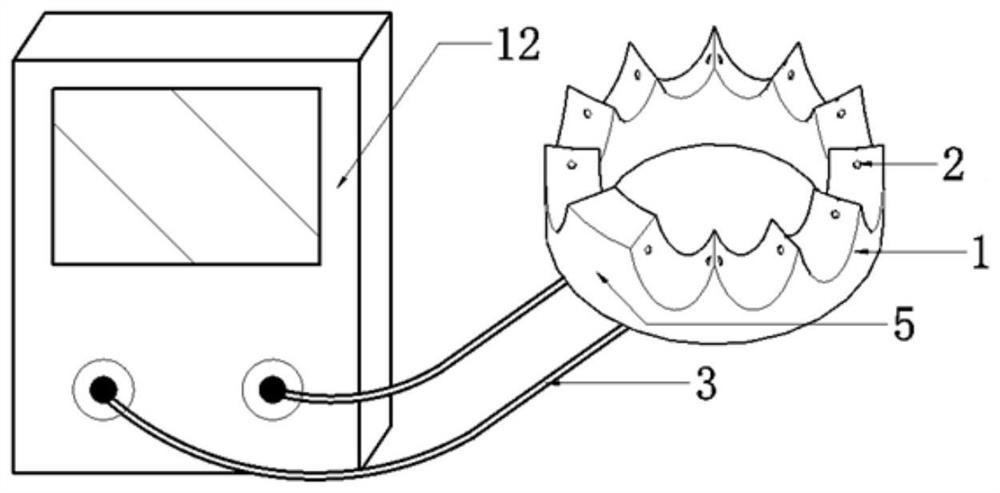

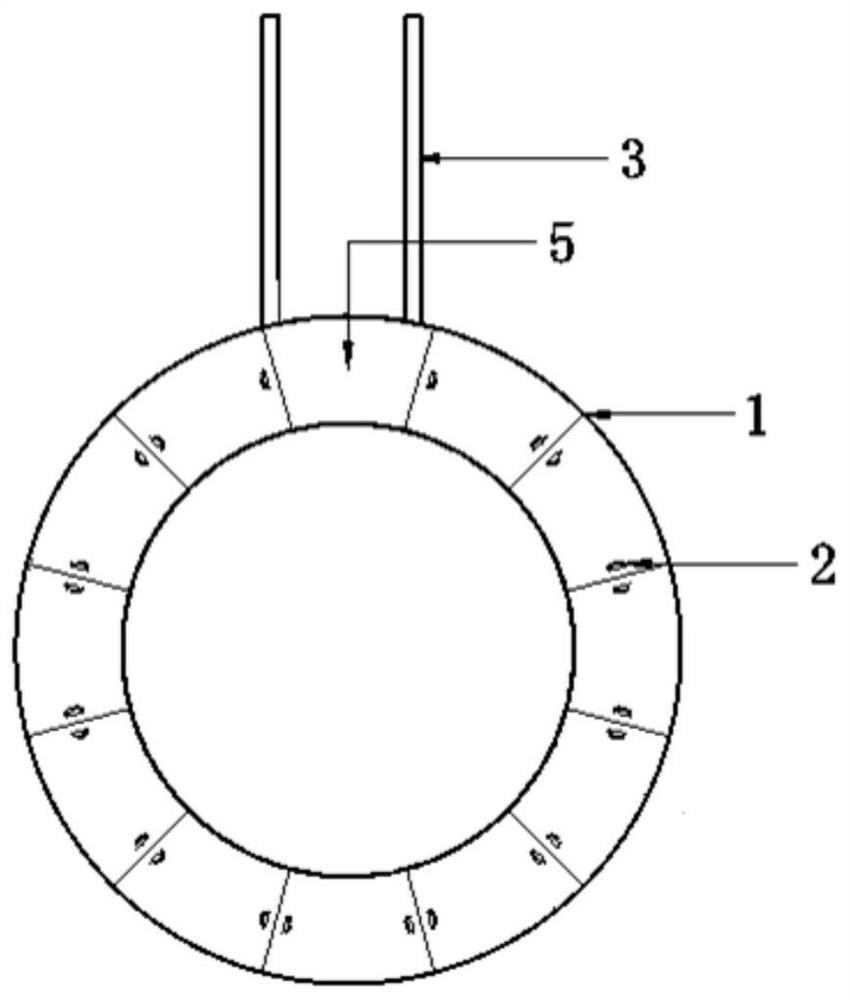

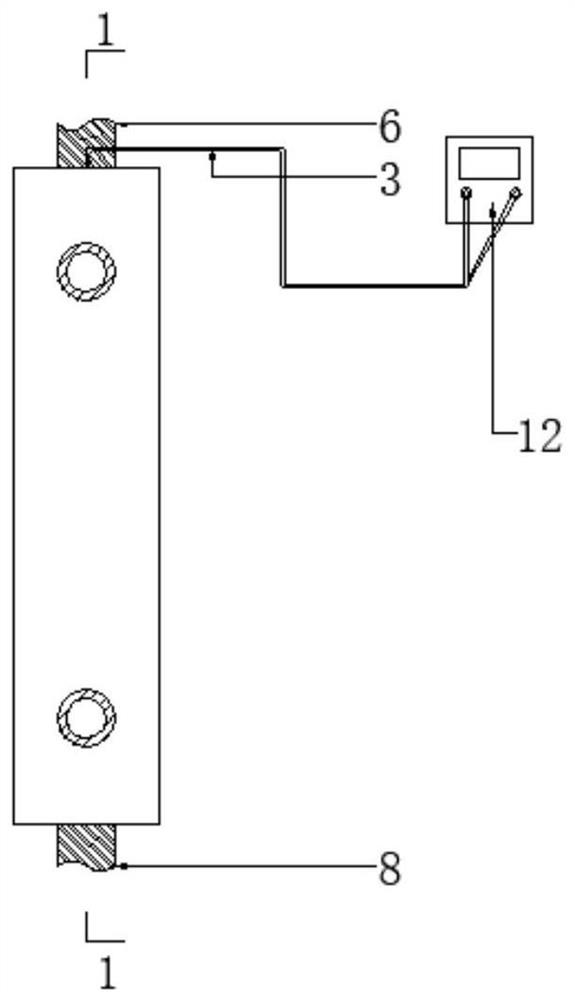

[0018] Such as figure 1 As shown, a sleeve grouting quality detection device according to the present invention includes an insulating base 1 , an inner wire 2 , an outer wire 3 and a feedback device 12 . The insulating base 1 is a hollow cylinder, and a circle of gear-shaped protrusions is arranged on the annular top surface of the cylinder wall. Such as figure 2 As shown, a section of inner wire is buried in each gear, and the two ends of the inner wire of each section are exposed. The upper end of the insulating base 1 is designed as a gear-shaped protrusion. The advantage is that the circuit can only be connected when the grouting material covers all the exposed ends of the inner wires. When one or more than one wire ends are not filled , a loop cannot be formed. The aspect ratio of the gears is more than 1.5 times. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com