Power battery high voltage relay control circuit and fault diagnosis method

A high-voltage relay and control circuit technology, applied in circuit breaker testing, instrumentation, electrical measurement, etc., can solve the problem that the battery control unit hardware architecture measurement and random hardware failure rate index are difficult to meet the safety integrity level and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

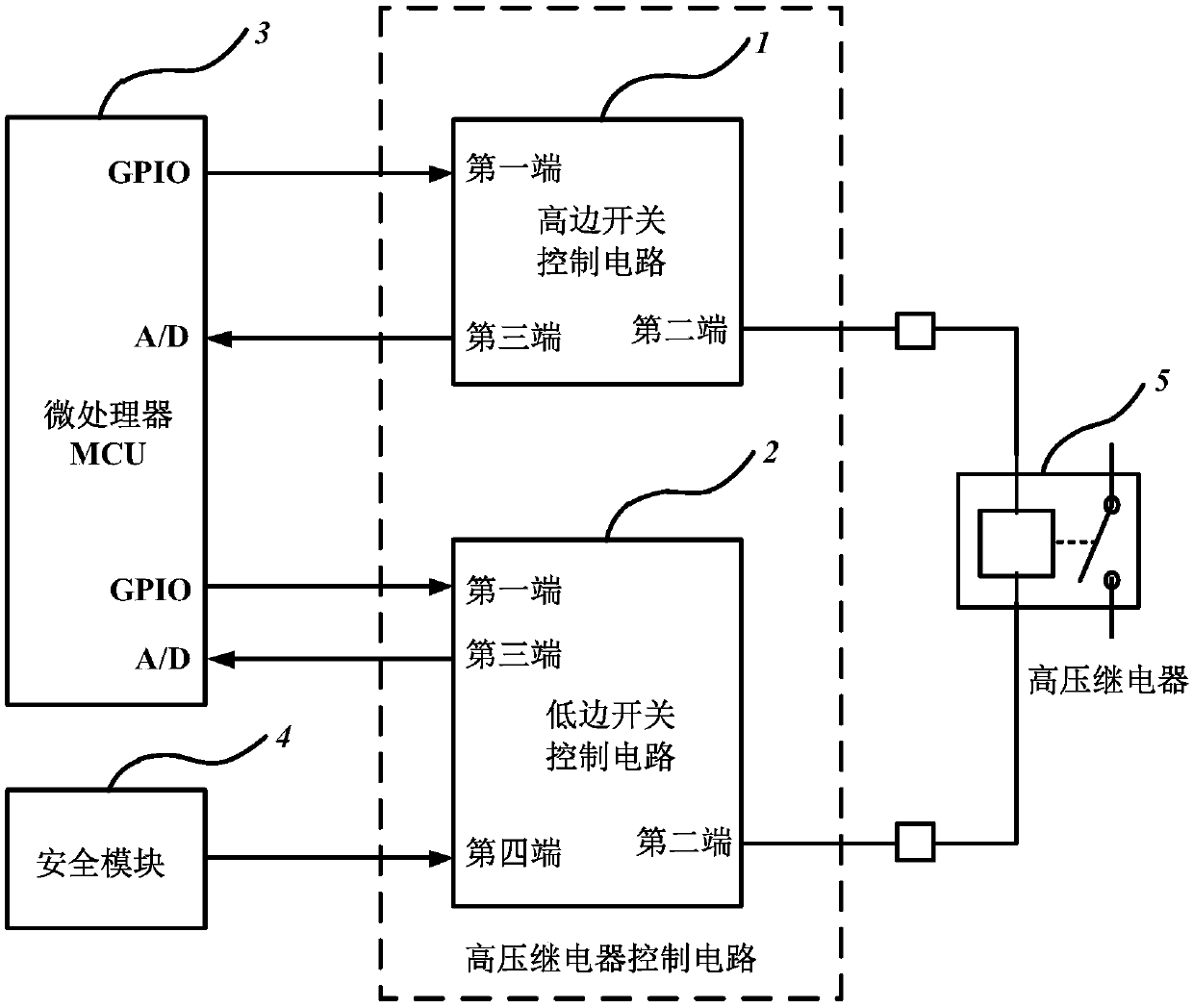

[0039] This embodiment provides a power battery high voltage relay control circuit, which includes a high-side switch control circuit 1 and a low-side switch control circuit 2 .

[0040] Such as image 3 As shown, the first end of the high-side switch control circuit 1 is connected to an output port of the MCU3, the second end of the high-side switch control circuit 1 is connected to one end of the coil of the high-voltage relay 5, and the first end of the high-side switch control circuit 1 Three terminals are connected to an A / D input port of the MCU; the first end of the low-side switch control circuit 2 is connected to an output port of the MCU, and the second end of the low-side switch control circuit 2 is connected to the other end of the coil of the high-voltage relay , the third end of the low-side switch control circuit 2 is connected to an A / D input port of the MCU, and the fourth end of the low-side switch control circuit 2 is connected to an output port of the secur...

Embodiment 2

[0053] This embodiment provides a fault diagnosis method for the power battery high-voltage relay control circuit, which is based on the relationship between the feedback voltage value of the A / D input port of the MCU and the diagnosis threshold voltage, and realizes the fault by combining the states of the high-side switch and the low-side switch. diagnostics, and includes fault diagnostics for the high-side switch control circuit and fault diagnostics for the low-side switch control circuit.

[0054] In this example, if Figure 6 As shown, the fault diagnosis of the high-side switch control circuit includes:

[0055] The MCU regularly reads the fault diagnosis signal V of the high-side switch control circuit 1 every 10ms. DIAGH ; Put the corresponding low-side switch control circuit in the conduction state, and judge whether the low-side switch control circuit fails, if the low-side switch control circuit fails, then end the fault diagnosis of the high-side switch control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com