AGV (Automated Guide Vehicle) path planning method based on minimum turning cost

A path planning and shortest path technology, applied in the field of AGV, can solve the problem of short turning time, avoid a large number of turns, and improve transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

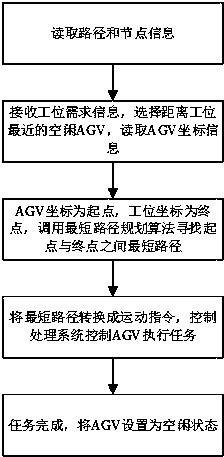

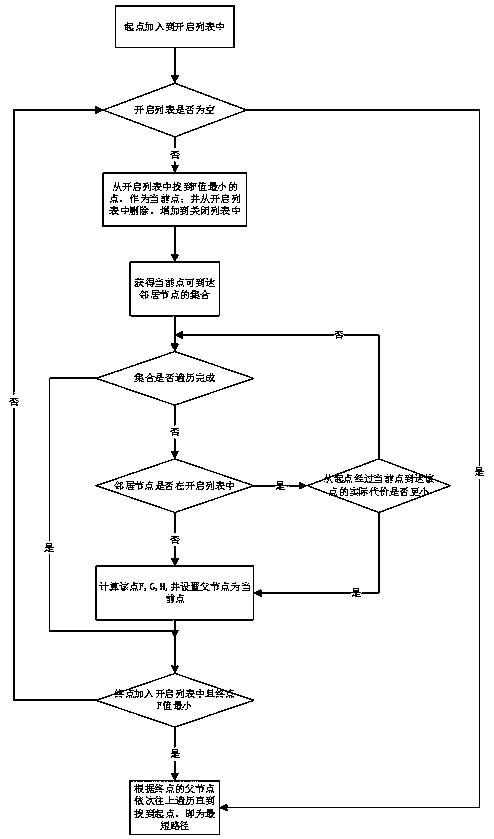

[0057] The present invention provides an AGV path planning method based on the minimum turning cost, such as figure 1 and figure 2 As shown, the method includes the following steps:

[0058] The upper computer system reads the path and node information according to the pre-drawn map model, and marks the node coordinates; the upper computer system receives the demand information sent by the station and sends the demand information to the control processing system of each AGV; The control processing system receives the demand information, judges whether the current AGV is in an idle state, if not, does not execute the task; if yes, obtains the coordinate information of the current AGV, and sends it to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com