Composite separator for lithium ion battery

A lithium-ion battery and separator technology, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of difficulty in replenishing active lithium loss, poor tensile and puncture resistance of separators, and reduce heat Loss of control, alleviation of swelling, effect of increasing discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

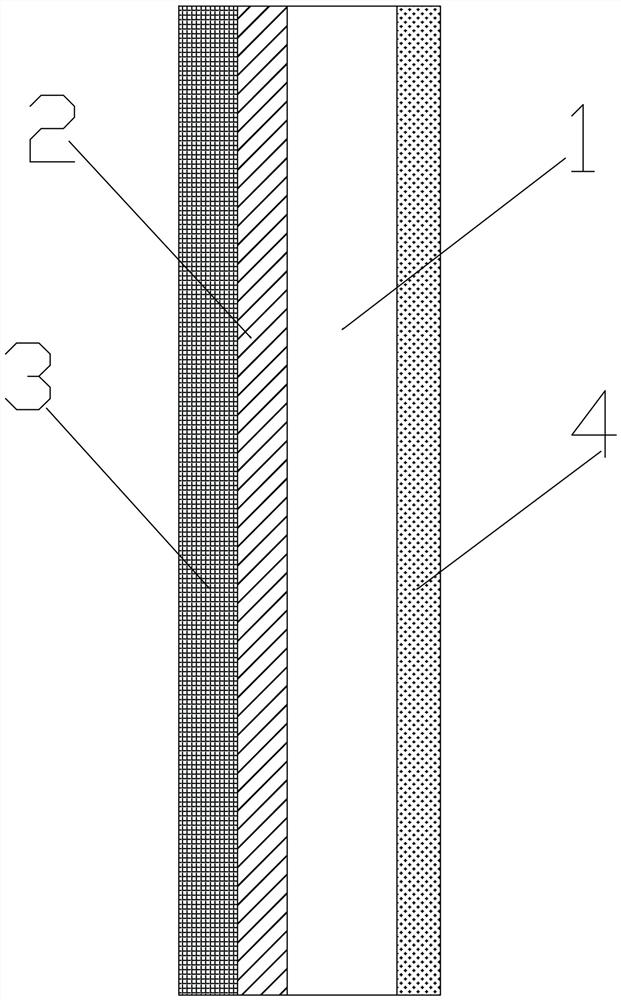

[0020] Embodiment 1: a kind of lithium ion battery composite separator described in this embodiment, comprises base film 1, is coated with gel coating 3 on the surface of base film 1 towards negative electrode side, between base film 1 and gel A buffer ceramic coating 2 is coated between the coatings 3, and a heat-sensitive semiconductor lithium-supplementing coating 4 is coated on the surface of the base film 1 facing the positive electrode; the composite separator is prepared by the following steps:

[0021] Step 1. Preparation of Buffer Ceramic Coating

[0022] Add 32kg of ferric phosphate with a D50 of 1.5μm, 4.8kg of polyurethane binder, 0.4kg of sulfonic acid sodium salt dispersant and 42.8kg of deionized water into a stirring tank with a capacity of 100L, and stir for 5 hours at a speed of 1500rpm , to obtain a buffer ceramic coating slurry with a viscosity of 200mPa·s. Using the gravure printing coating process, the slurry was coated on the surface of one side of the ...

Embodiment 2

[0027] Embodiment 2: a kind of lithium ion battery composite separator described in this embodiment, comprises base film 1, is coated with gel coating 3 on the surface of base film 1 towards the negative electrode side, between base film 1 and gel A buffer ceramic coating 2 is coated between the coatings 3, and a heat-sensitive semiconductor lithium-supplementing coating 4 is coated on the surface of the base film 1 facing the positive electrode; the composite separator is prepared by the following steps:

[0028] Step 1. Preparation of Buffer Ceramic Coating

[0029] 12kg of iron oxide with D50 of 0.5μm, 12kg of iron phosphate with D50 of 0.5μm, 0.8kg of polyurethane adhesive, 0.8kg of polyacrylic adhesive, 0.08kg of carboxylic acid sodium salt dispersant and 54.32kg of deionized Water was added to a stirring tank with a capacity of 100 L, and stirred at a speed of 2200 rpm for 1 h to obtain a buffer ceramic coating slurry with a viscosity of 50 mPa·s. Using the gravure prin...

Embodiment 3

[0034] Embodiment 3: A kind of composite separator of lithium ion battery described in this embodiment, comprises base film 1, is coated with gel coating 3 on the surface of base film 1 towards negative electrode side, between base film 1 and gel A buffer ceramic coating 2 is coated between the coatings 3, and a heat-sensitive semiconductor lithium-supplementing coating 4 is coated on the surface of the base film 1 facing the positive electrode; the composite separator is prepared by the following steps:

[0035] Step 1. Preparation of Buffer Ceramic Coating

[0036] 16kg of manganese dioxide with D50 of 1 μm, 12kg of manganese trioxide with D50 of 1 μm, 2.4kg of polyurethane adhesive, 0.8kg of polyimide adhesive, 0.08kg of sulfonic acid sodium salt dispersant, 0.24 kg of carboxylic acid sodium salt dispersant and 48.48 kg of deionized water were added to a stirring tank with a capacity of 100 L, and stirred at a speed of 1800 rpm for 3 h to obtain a buffer ceramic coating slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com