A liquid-cooled heat dissipation circulation loop device for blade server

A blade server and circulation loop technology, applied in cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. Small space, symmetrical and beautiful layout, and reduced pipeline flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the public implementation manners of the present invention in detail with reference to the accompanying drawings.

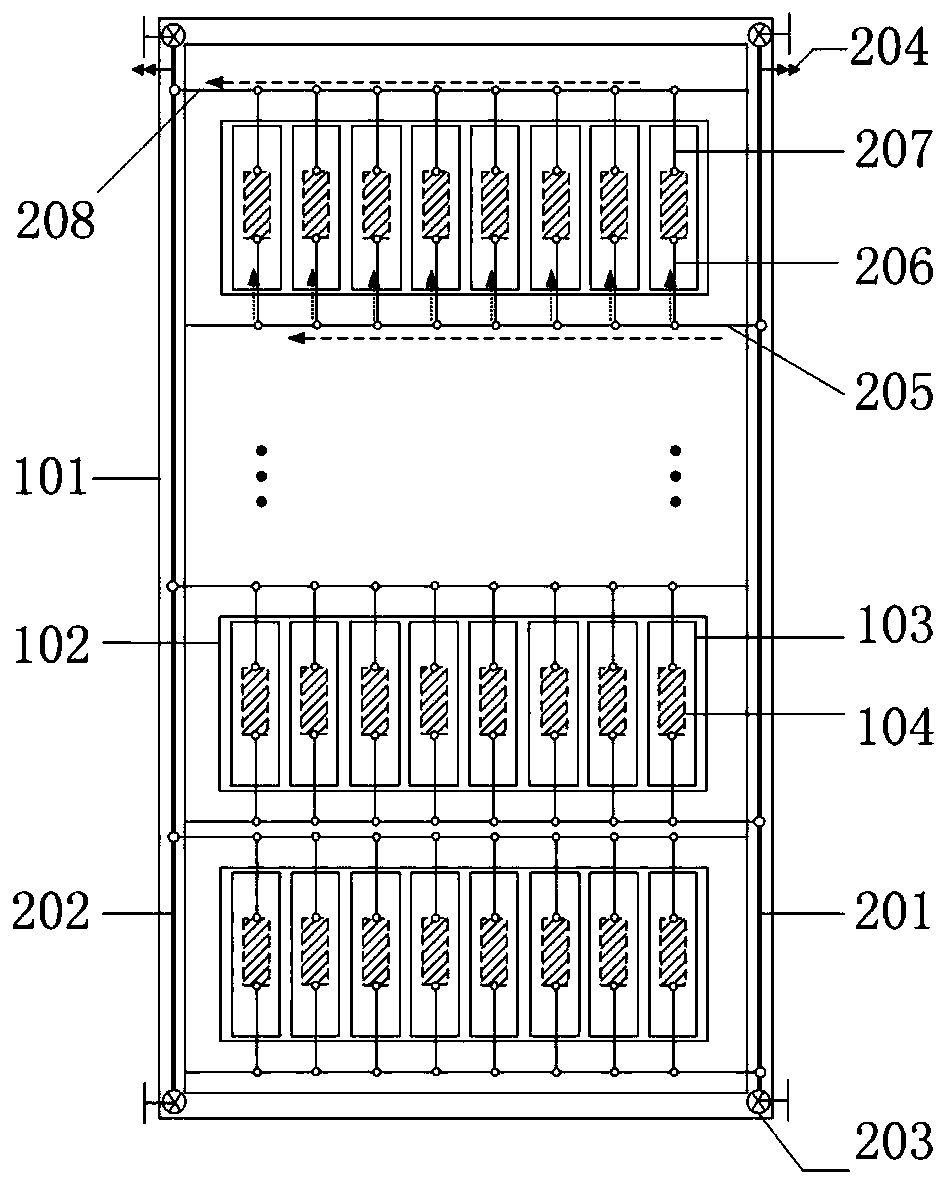

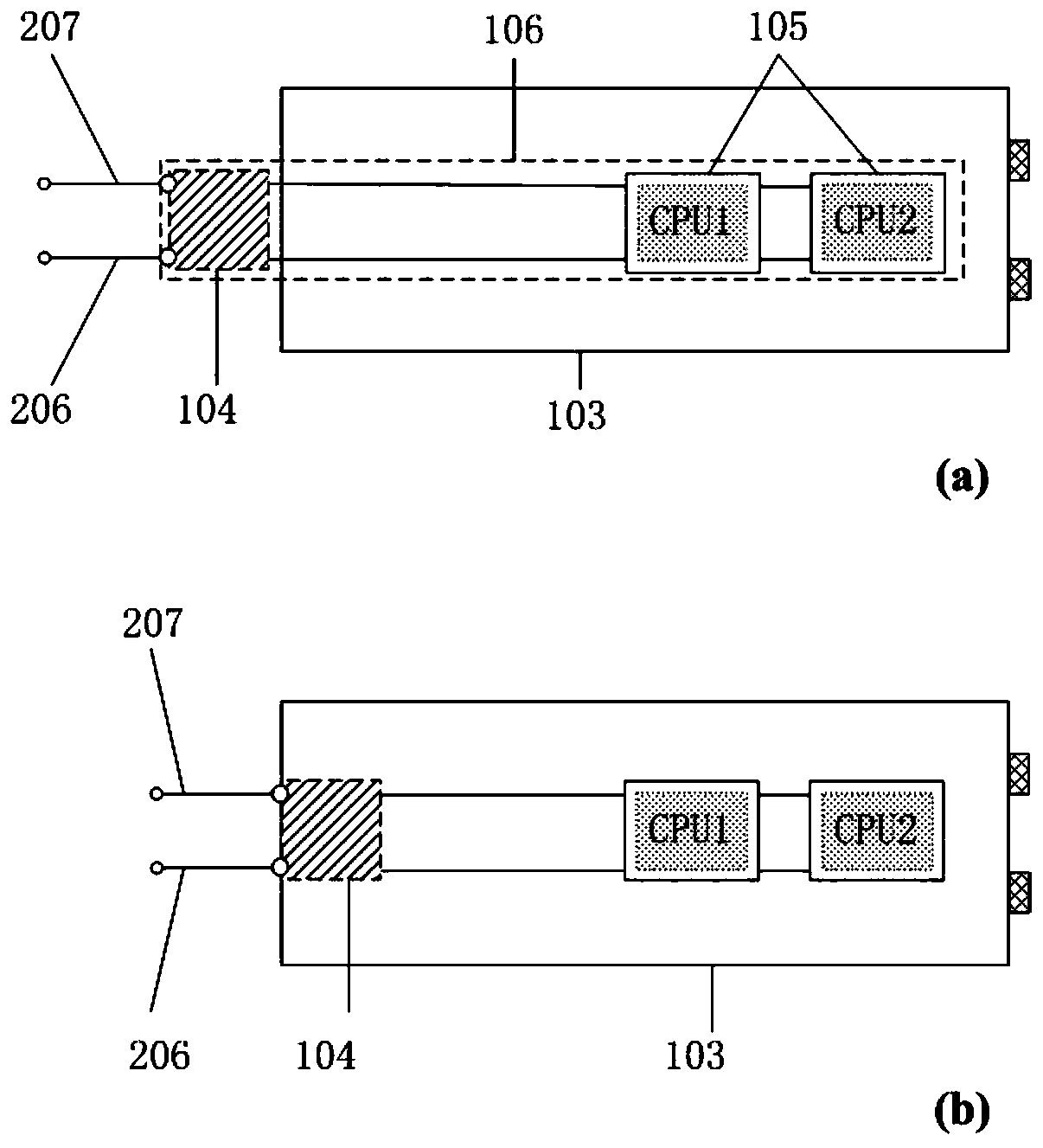

[0030] refer to figure 1 A specific embodiment provided by the present invention includes a liquid supply main pipe 201 and a liquid return main pipe 202, valves 203 located at the upper and lower ends of the liquid supply main pipe 201 and the liquid return main pipe 202, and valves 203 located at the liquid supply main pipe 201 and the liquid return main pipe. The exhaust valve 204 at the upper end of 202 , the first branch liquid supply pipe 205 and the first branch liquid return pipe 208 , the second branch liquid supply pipe 206 and the second branch liquid return pipe 207 , and the heat pipe unit 106 .

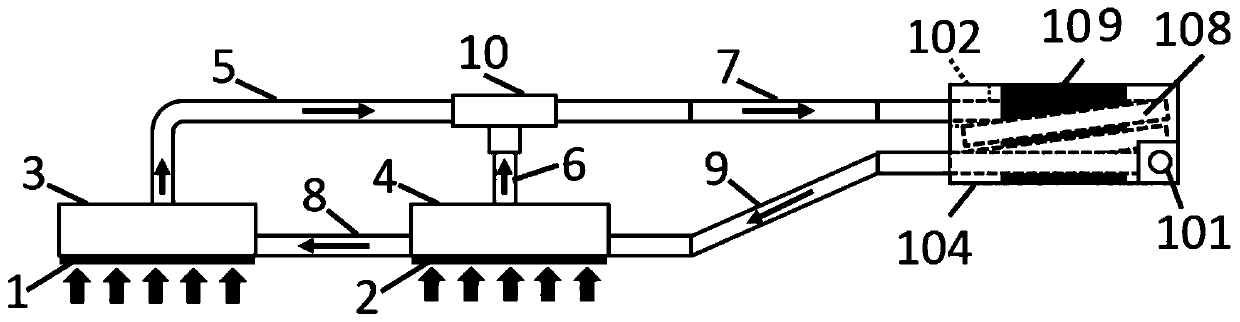

[0031] Wherein, the heat pipe unit 106 includes a gas pipe, a liquid pipe, an evaporating end 105 and a cooling end ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap