Roll shaft used for brush roll

A roller shaft and brush roller technology, used in applications, household appliances, suction nozzles, etc., can solve problems such as fatigue failure and stress concentration, and achieve the effect of reducing the dynamic stress concentration factor, eliminating high stress concentration and extending the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

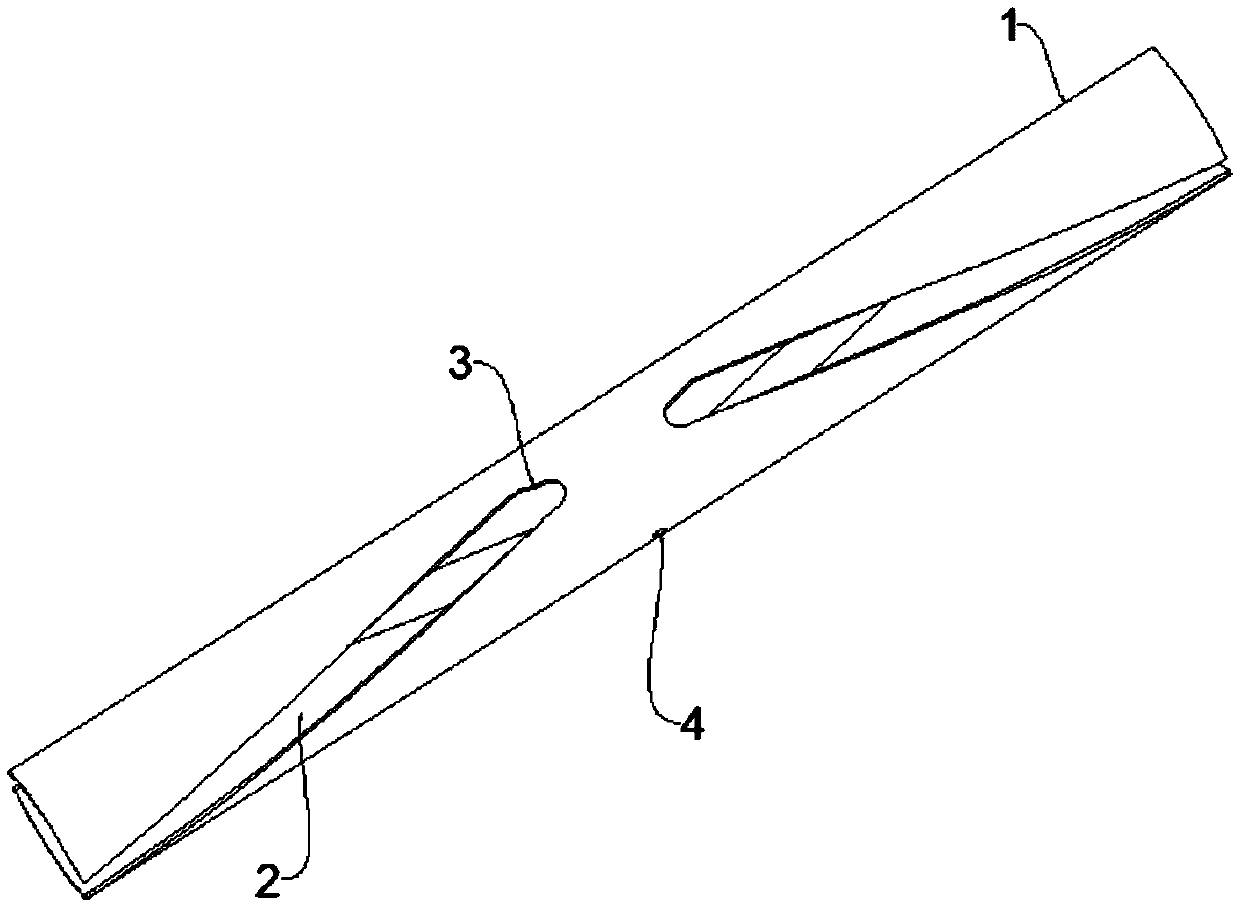

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

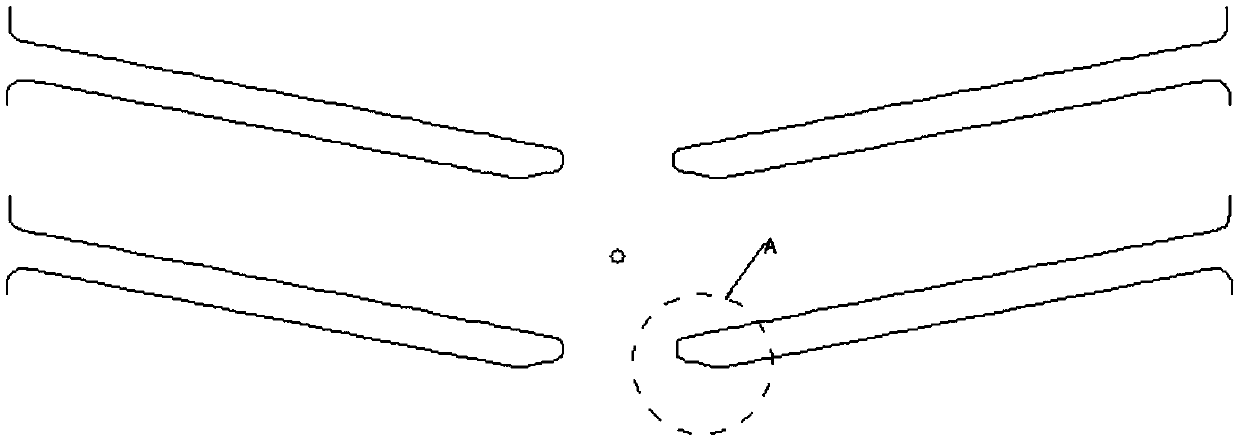

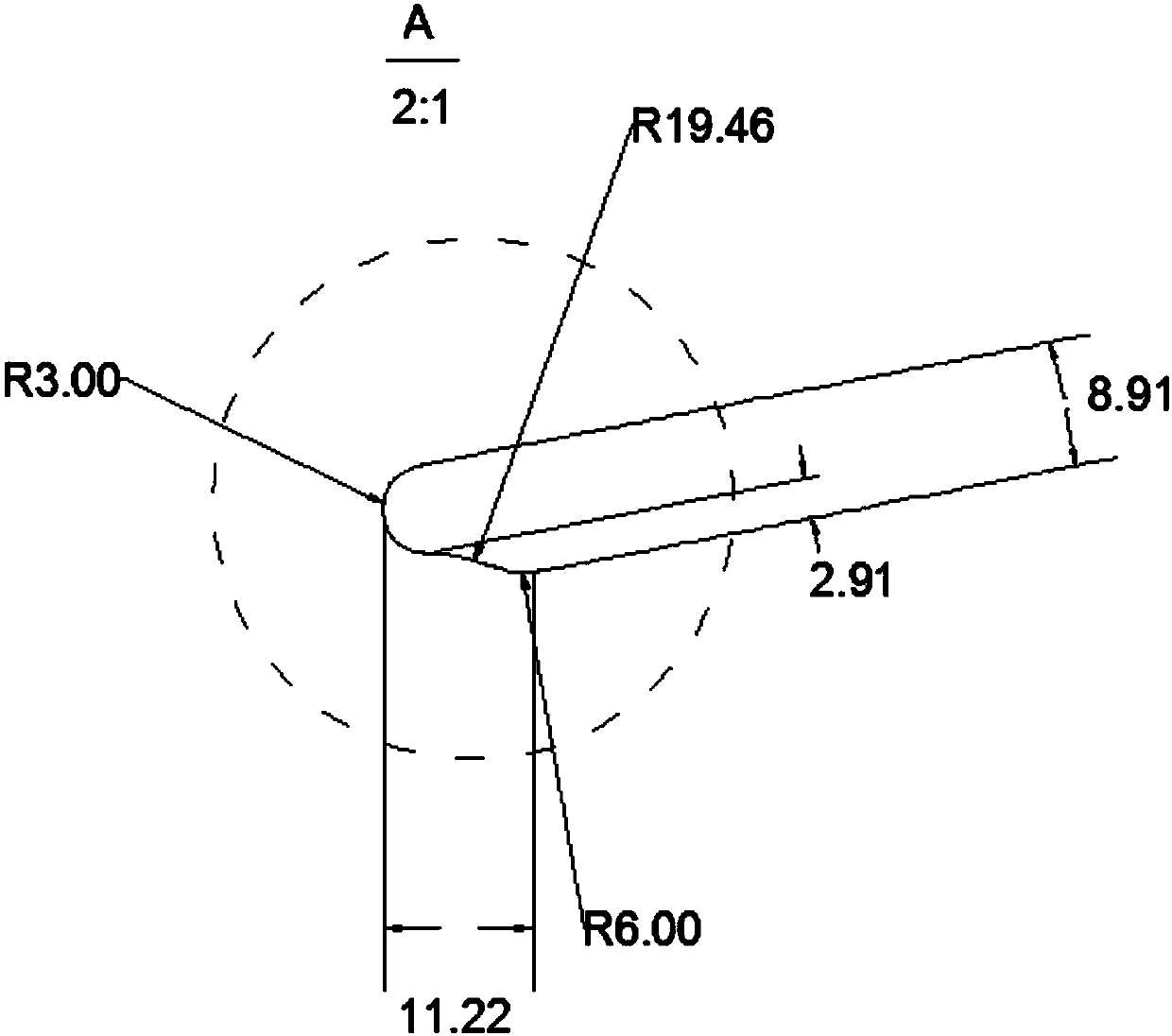

[0031] Figure 4 It shows the groove structure of the general roller shaft on the market, and its end adopts a single arc transition structure. During the working process of this structure, especially at the dynamic moment of starting or receiving impact, the intersection of the helix and the arc section is equivalent to a A smooth transition notch, resulting in stress concentration at this place, will lead to crack initiation and propagation during repeated use, and eventually fatigue failure, as follows:

[0032] 1. If Figure 5 As shown, assuming that the brush roller bears a uniformly distributed load of 60 lbs, when its full cross-section is stressed,

[0033] Stress level P=F / S=60*0.4S4*9.8 / 12S*1=2.14MPa;

[0034] Referring to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap