Gutta percha point cutter having planishing function and production method of head of gutta percha point cutter

A technology of cutter and gutta-percha, which is applied in dentistry, filling teeth, orthodontics, etc., can solve the problem of not being able to press the gutta-percha tip equally, and achieve the effect of fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

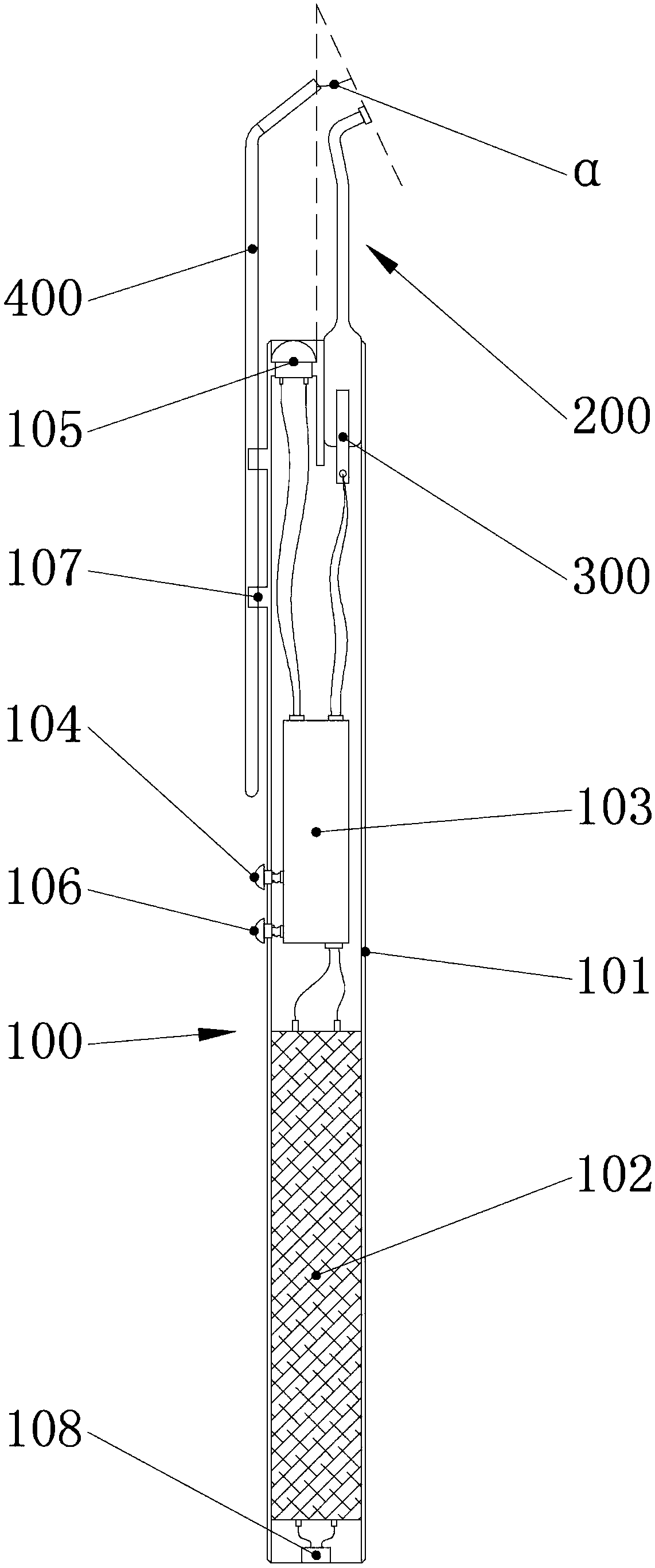

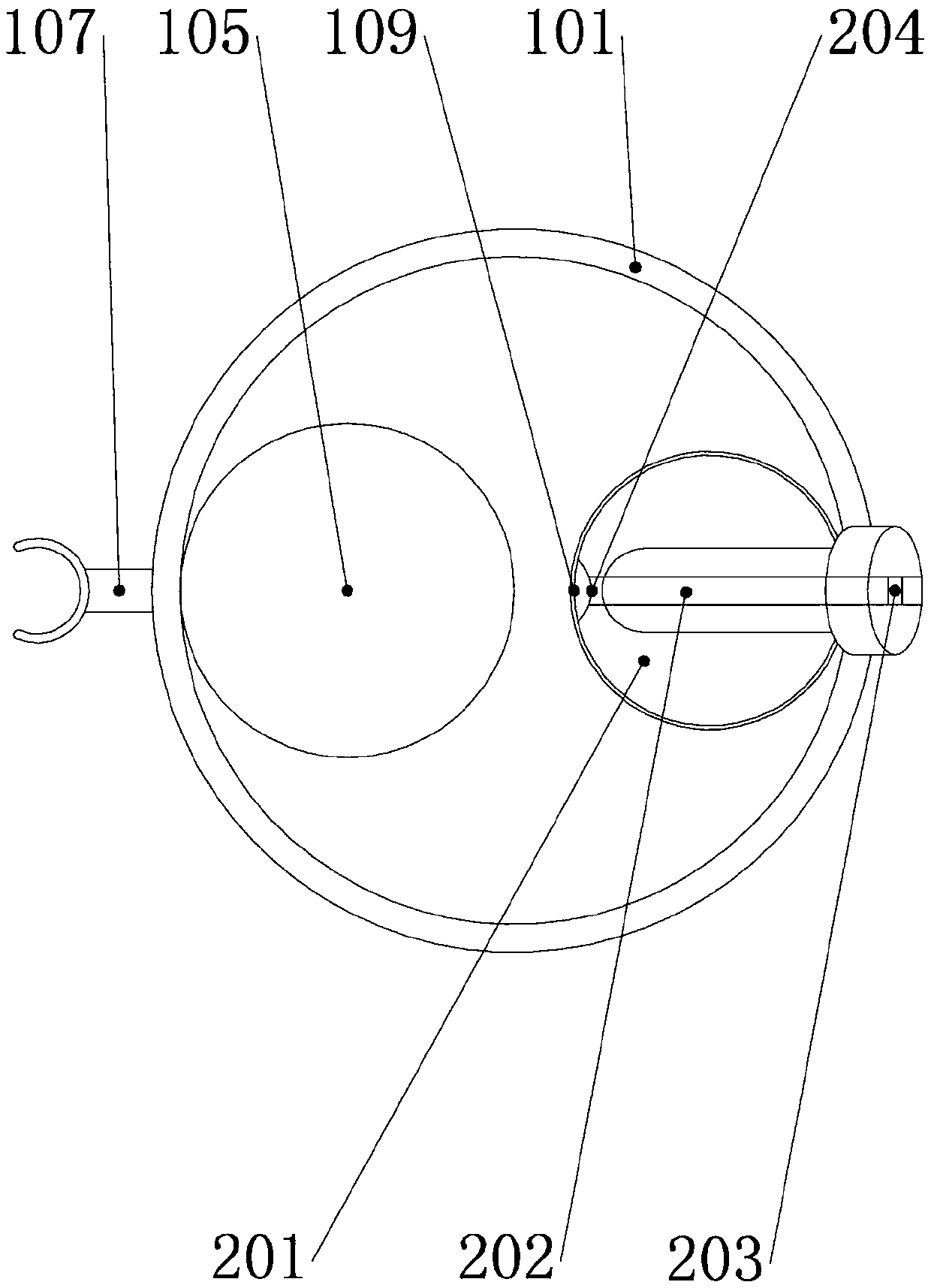

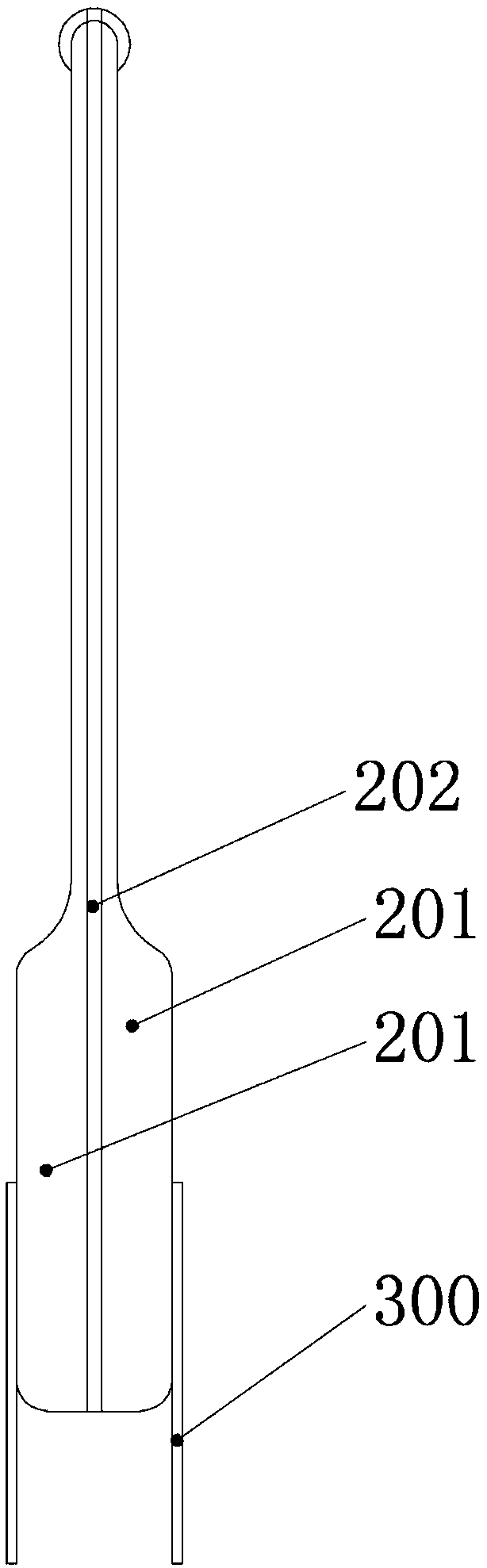

[0026] A gutta-percha tip cutter with a flattening function, comprising a body 100 and a head 200, the front end of the body 100 is provided with a mounting hole for mounting the head 200, and a metal wire for conducting electricity is provided in the mounting hole. The shrapnel 300, the head 200 includes two mutually symmetrical metal components 201, an insulating layer 202 is provided between the two metal components 201, and the metal component 201 and the insulating layer 202 formed by the two petals The front end of the head is cylindrical, and the front ends of the two lobes of the metal member 201 are connected by a metal sheet 203. The resistance of the metal sheet is greater than that of the metal member, and the rear end of the head 200 is inserted into the installation hole. , the two lob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com