Wind adsorption polyester peach skin shoe vamp gluing machine based on forward and reverse rotating and smoothening

A peach skin, positive and negative technology, applied in the field of gluing machines for peach skin uppers, can solve the problems of damaged feet, difficult to clean, loss of luster and softness of plush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

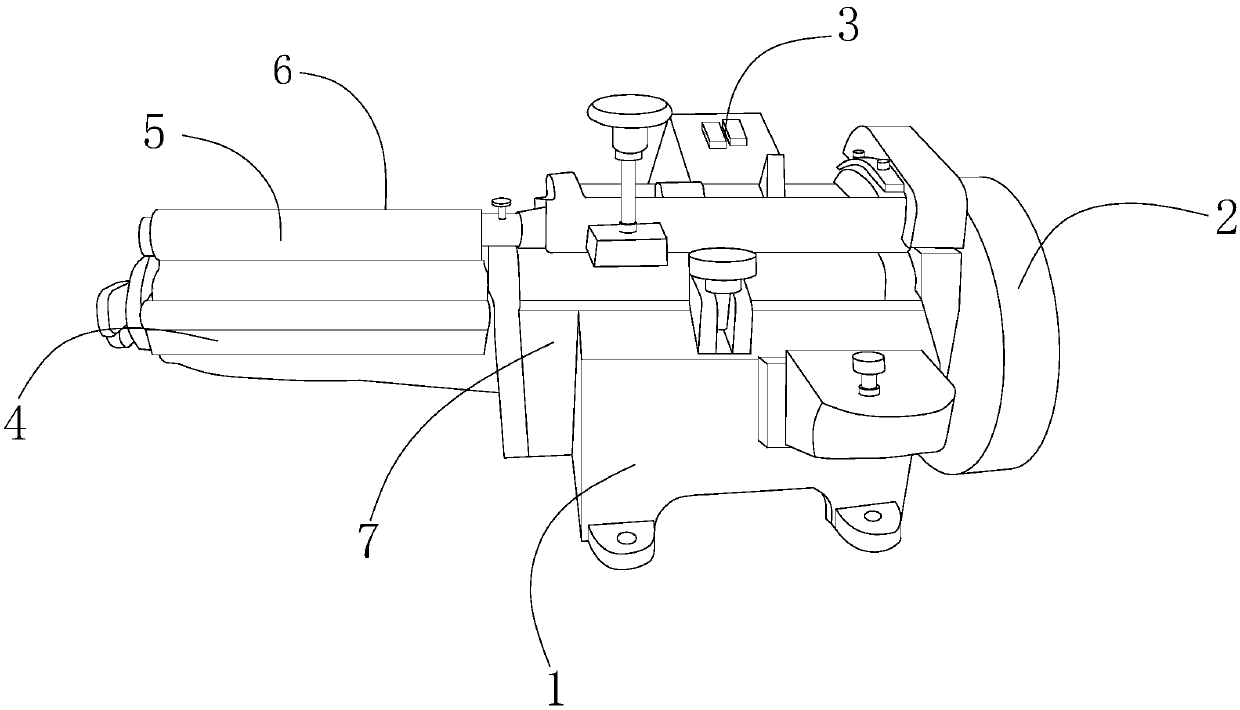

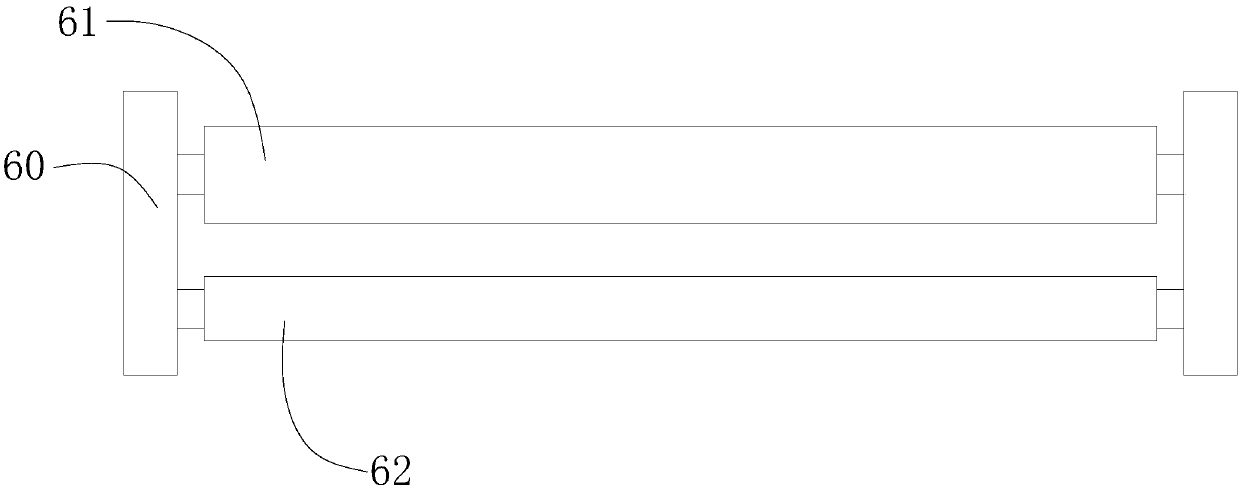

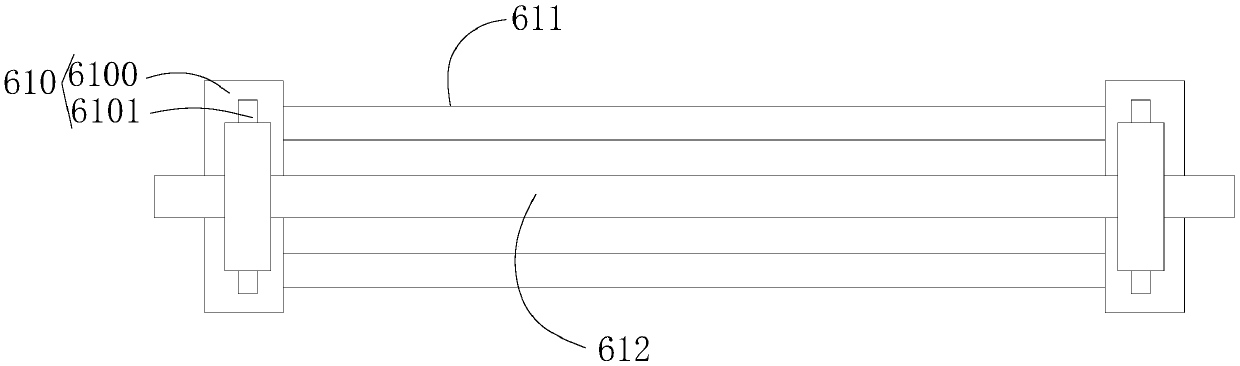

[0029] Such as Figure 1-Figure 6 As shown, the present invention provides a technical scheme of wind adsorption based on the gluing machine for jeanette vamps that is rotated forward and reverse and smoothed:

[0030] Such as Figure 1-Figure 2 As shown, a gluing machine for jeanette vamps that is based on positive and negative rotation and smoothing by wind force adsorption, its structure includes a device main body 1, a transmission shaft 2, a control switch 3, a workbench 4, a rubber roller shaft 5, Smoothing device 6, air extraction system 7, the transmission shaft 2 is installed on the right side of the equipment main body 1 and connected by electric welding, the control switch 3 is installed on the rear of the equipment main body 1 and ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com