Permanent magnetic material prepared from bayan obo symbiotic and concomitant raw ore mixed rare earth and preparation method thereof

A technology of mixed rare earth and permanent magnet materials, which is used in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of low content, and achieve the effects of low rare earth content, improved magnetic properties, and high coercivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

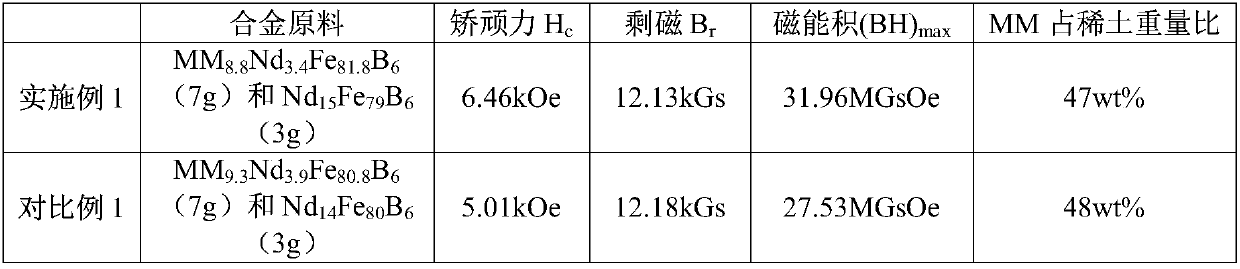

Embodiment 1

[0036] A permanent magnet material prepared by using mixed rare earths from Baiyun Obo co-associated raw ore, the raw materials include (MM, RE)-Fe-B alloy powder and (Nd, Pr)-Fe-B alloy powder containing mixed rare earth MM, (MM, The chemical formula of RE)-Fe-B is MM by atomic percentage 8.8 Nd 3.4 Fe 81.8 B 6 , (Nd,Pr)-Fe-B chemical formula is Nd by atomic percentage 15 Fe 79 B 6 .

[0037] Its preparation method comprises the following steps:

[0038] Step 1: Weigh MM according to the composition design requirements 8.8 Nd 3.4 Fe 81.8 B 6 and Nd 15 Fe 79 B 6 The ingredients are mixed in proportion to prepare a mixture of two alloys;

[0039] Step 2: Induction heating (1100°C, 2h) of each alloy component mixture prepared in step 1 is carried out under vacuum conditions to melt each alloy component mixture into a liquid, and then cooled to obtain MM 8.8 Nd 3.4 Fe 81.8 B 6 and Nd 15 Fe 79 B 6 Alloy ingots, ensure uniform composition during smelting to ens...

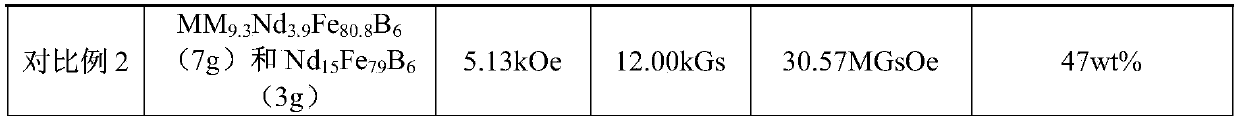

Embodiment 2

[0051] A permanent magnet material prepared by using mixed rare earths from Baiyun Obo co-associated raw ore, the raw materials include (MM, RE)-Fe-B alloy powder and (Nd, Pr)-Fe-B alloy powder containing mixed rare earth MM, (MM, The chemical formula of RE)-Fe-B is MM by atomic percentage 8.8 Nd 3.4 Fe 81.8 B 6 , (Nd,Pr)-Fe-B chemical formula is Nd by atomic percentage 15 Fe 79 B 6 .

[0052] Its preparation method comprises the following steps:

[0053] Step 1: Weigh MM according to the composition design requirements 8.8 Nd 3.4 Fe 81.8 B 6 and Nd 15 Fe 79 B 6 The ingredients are mixed in proportion to prepare a mixture of two alloys;

[0054] Step 2: Induction heating (1100°C, 2h) of each alloy component mixture prepared in step 1 is carried out under vacuum conditions to melt each alloy component mixture into a liquid, and then cooled to obtain MM 8.8 Nd 3.4 Fe 81.8 B 6 and Nd 15 Fe 79 B 6 Alloy ingots, ensure uniform composition during smelting to ens...

Embodiment 3

[0067] A permanent magnet material prepared by using mixed rare earths from Baiyun Obo co-associated raw ore, the raw materials include (MM, RE)-Fe-B alloy powder and (Nd, Pr)-Fe-B alloy powder containing mixed rare earth MM, (MM, The chemical formula of RE)-Fe-B is MM by atomic percentage 8.8 Nd 3.4 Fe 80.8 B 6 co 1 , (Nd,Pr)-Fe-B chemical formula is Nd by atomic percentage 15 Fe 79 B 6 .

[0068] Its preparation method comprises the following steps:

[0069] Step 1: Weigh MM according to the composition design requirements 8.8 Nd 3.4 Fe 80.8 B 6 co 1 and Nd 15 Fe 79 B 6 The ingredients are mixed in proportion to prepare a mixture of two alloys;

[0070]Step 2: Induction heating (1100°C, 2h) of each alloy component mixture prepared in step 1 is carried out under vacuum conditions to melt each alloy component mixture into a liquid, and then cooled to obtain MM 8.8 Nd 3.4 Fe 80.8 B 6 co 1 and Nd 15 Fe 79 B 6 Alloy ingots, ensure uniform composition durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com