Double-wheel milling power head and double-wheel milling deep stirring machine

A double-wheel milling and power head technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problem of limited cutting range of the power head lowering blade, insufficient power head downward movement, and side plate hard soil obstruction, etc. problems, to achieve the effect of widening the stirring range, convenient processing and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

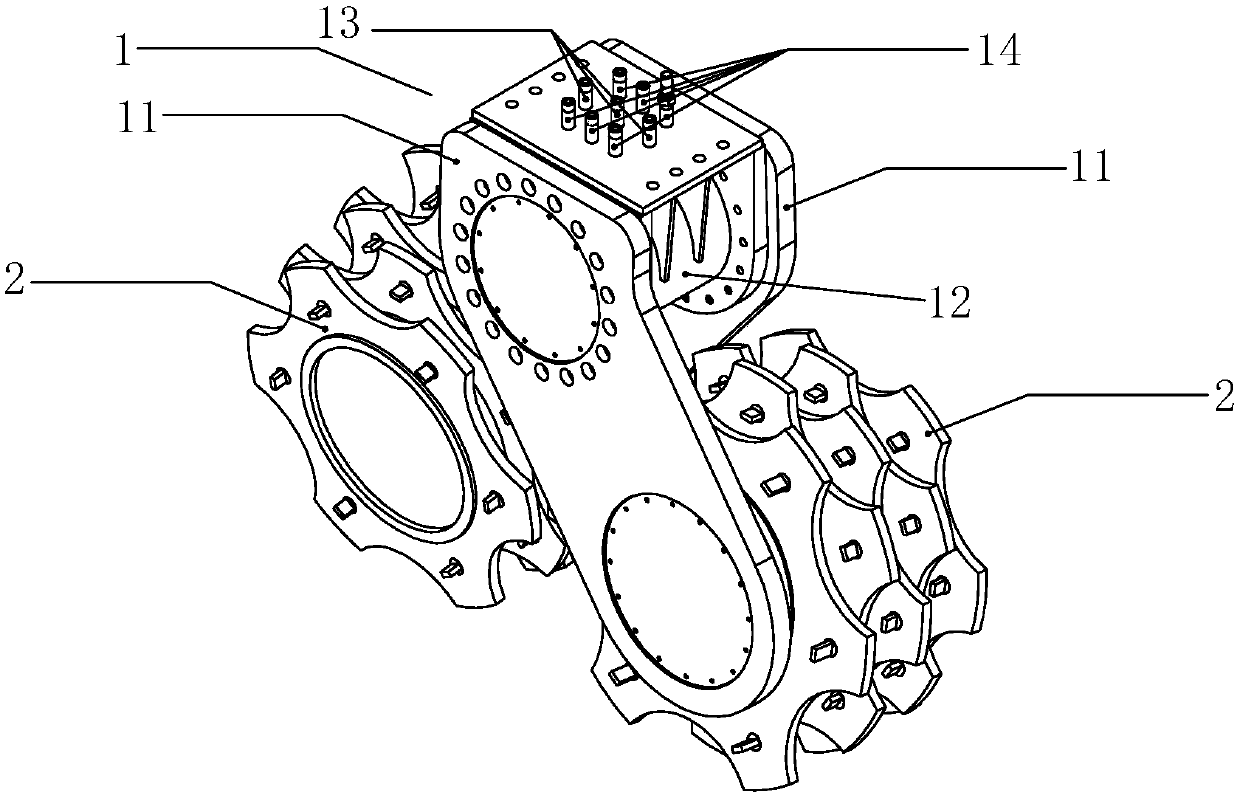

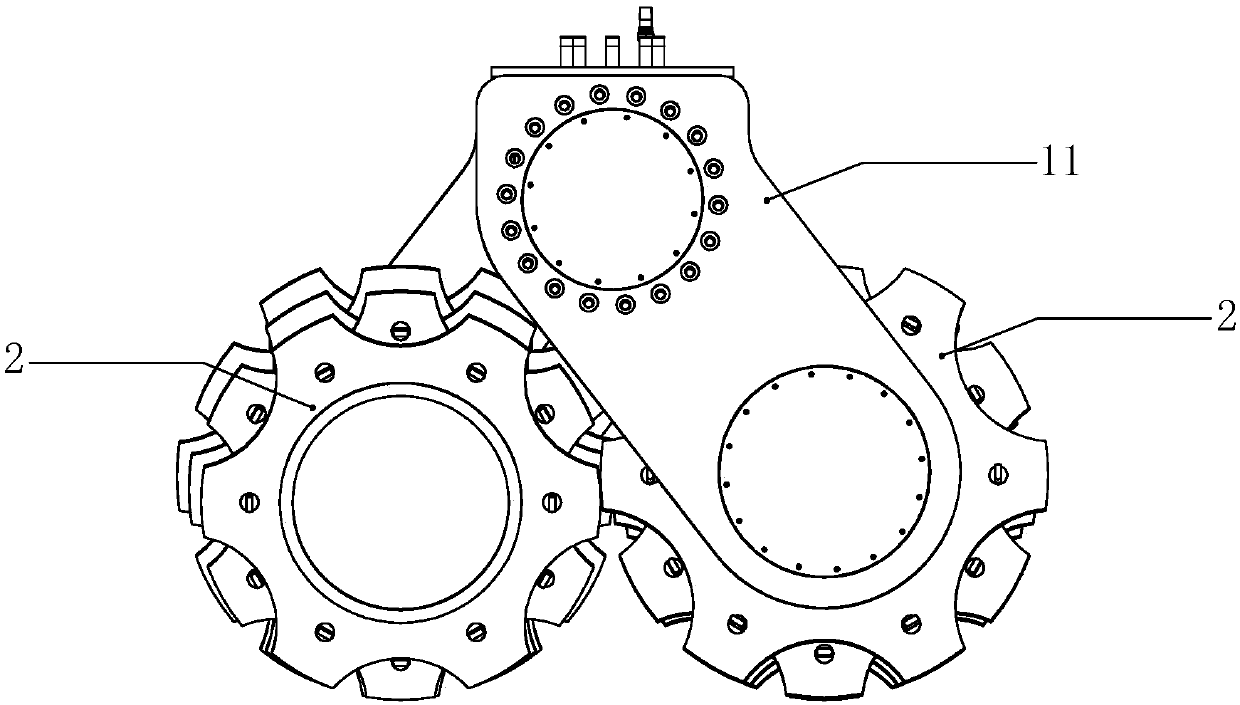

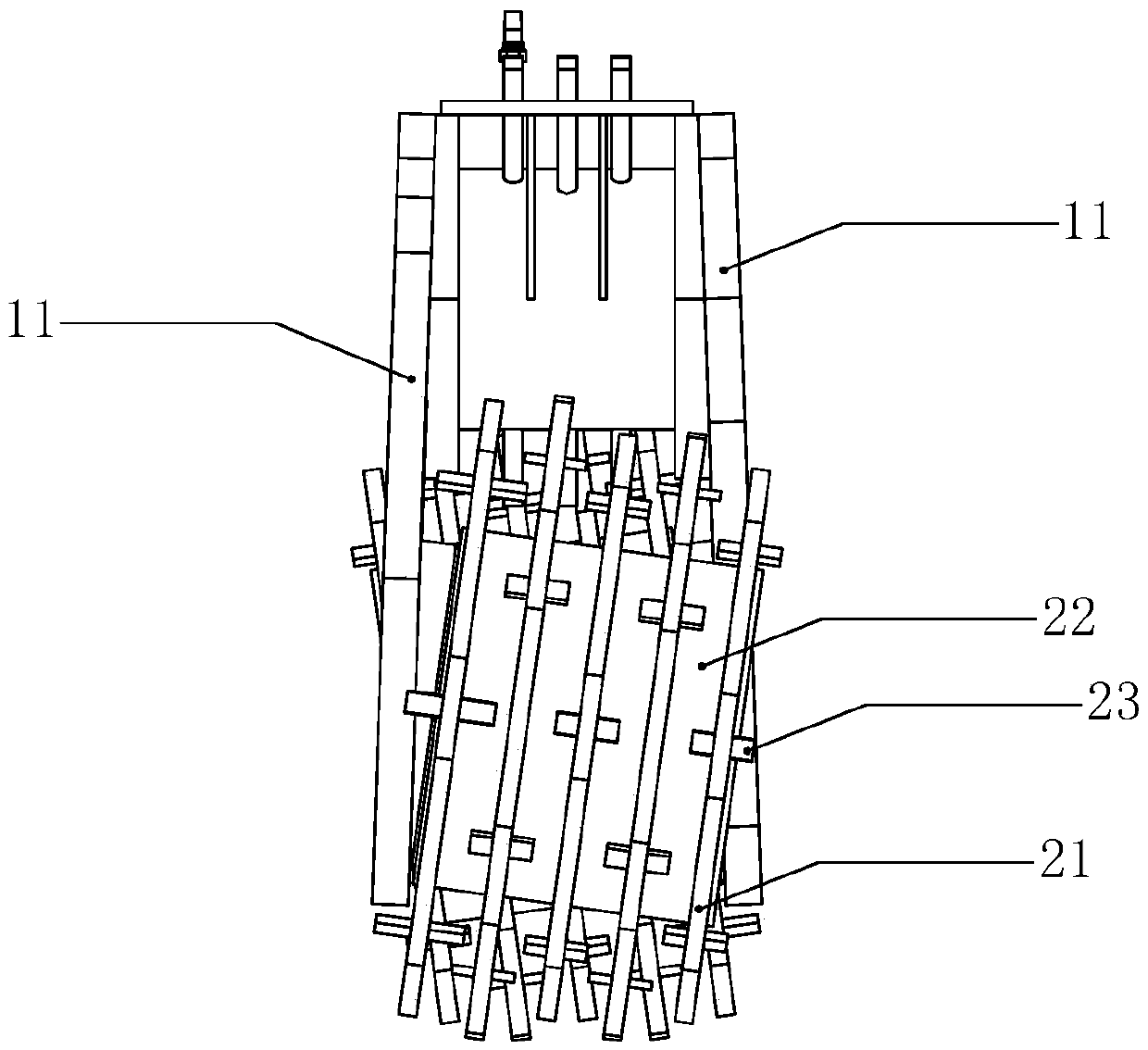

[0032] Examples, see Figure 1-Figure 9 As shown, a double-wheel milling power head of the present invention includes a mounting frame 1, two milling wheels 2, and a power mechanism. The mounting frame 1 has front and rear side plates 11, and the inner surfaces of the two side plates 11 are equipped with a Milling wheel (that is, the milling wheel is located on the inner surface of the side plate, but not limited to be installed on the side plate), two milling wheels 2 are distributed left and right. The power mechanism is arranged on the mounting frame 1 and connected with the milling wheels to drive the two milling wheels 2 to rotate in reverse; the two milling wheels 2 are respectively inclined to the inside of the two side plates 11, so that the vertical plane of the rotation axis of each milling wheel is in line with the milling wheel. An included angle β is formed between the side plates where the wheels are located (such as Figure 8 shown), the angle β is an acute ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com