Packing box manual locating, gluing and board sticking method

A technology for packing boxes and boards, which is applied in the field of manual positioning and glued boards for packaging boxes. It can solve problems such as inaccurate alignment and unqualified packaging, and achieve the effects of lowering the threshold, improving the pass rate, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

[0031] The invention provides a method for manual positioning, gluing and pasting of a packaging box, comprising the following steps:

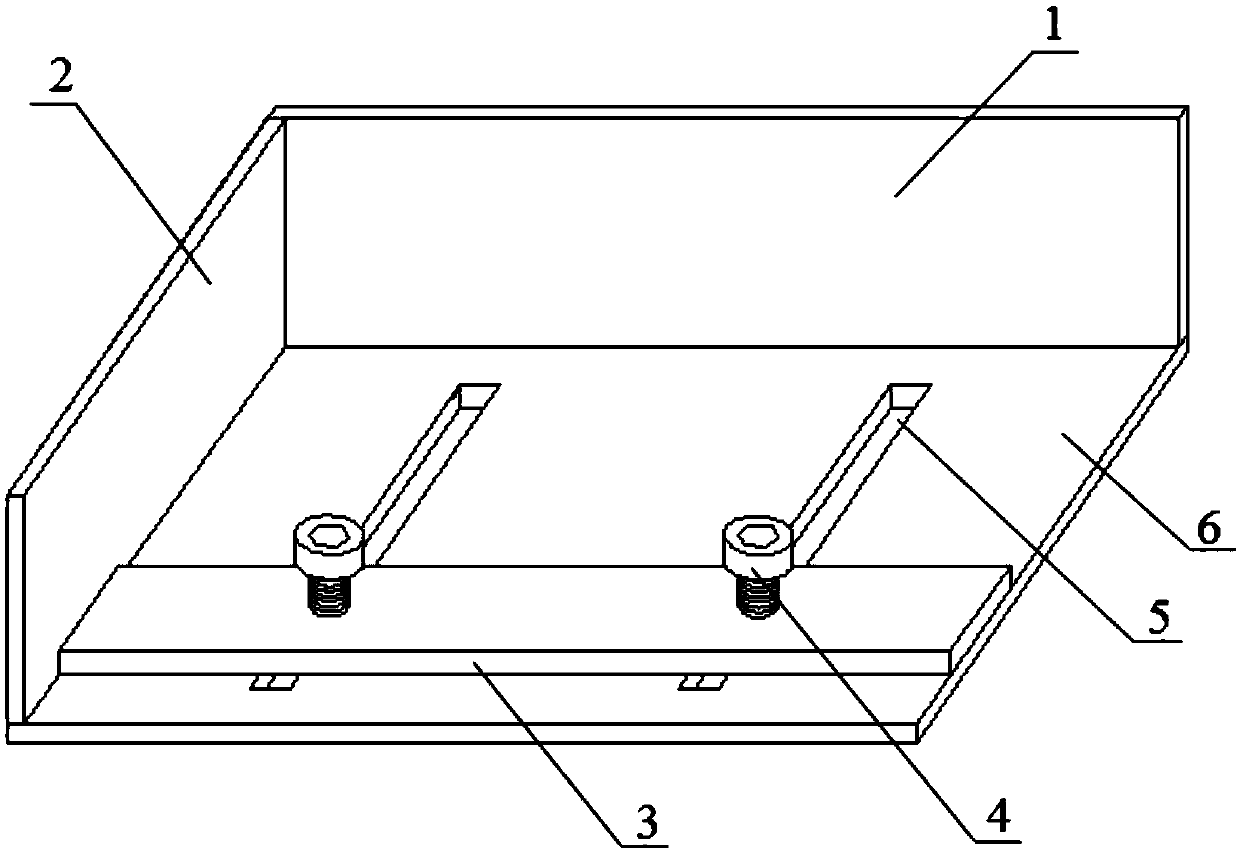

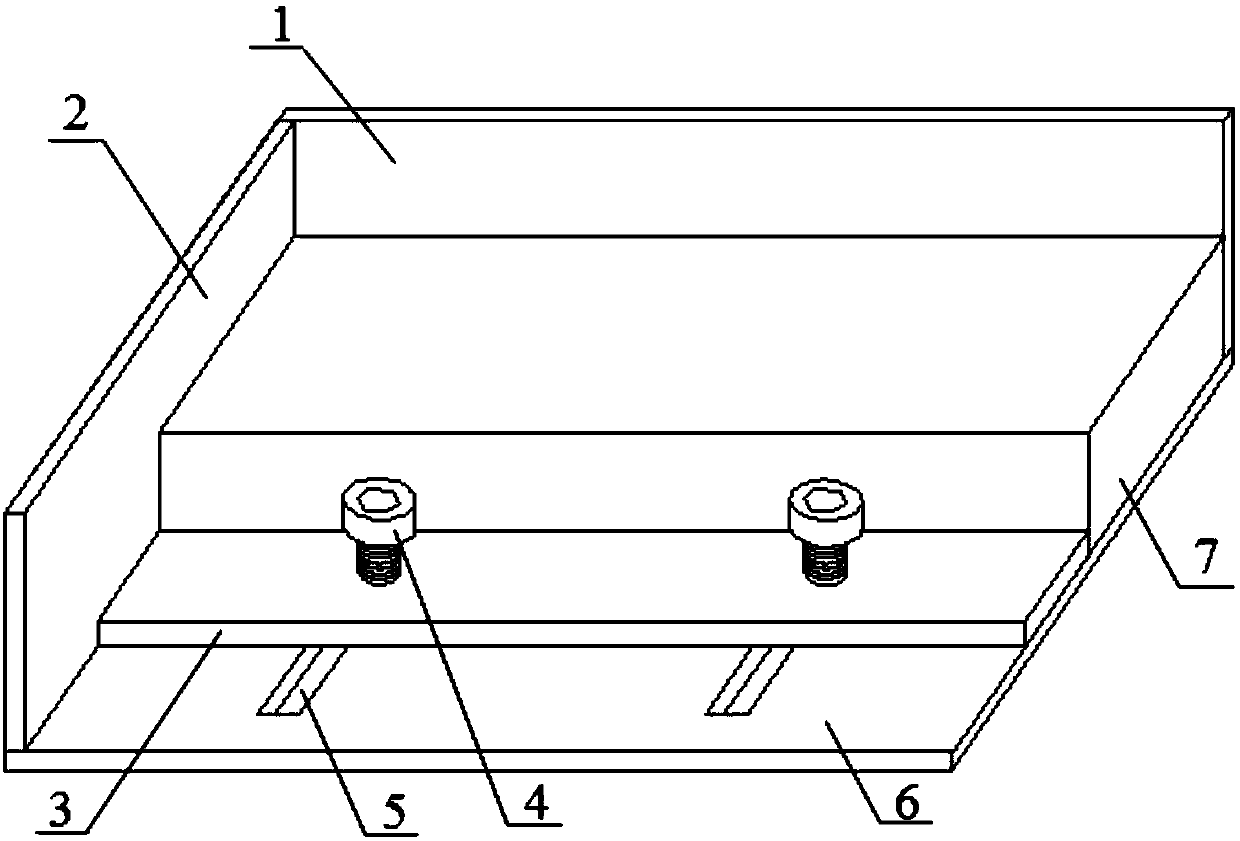

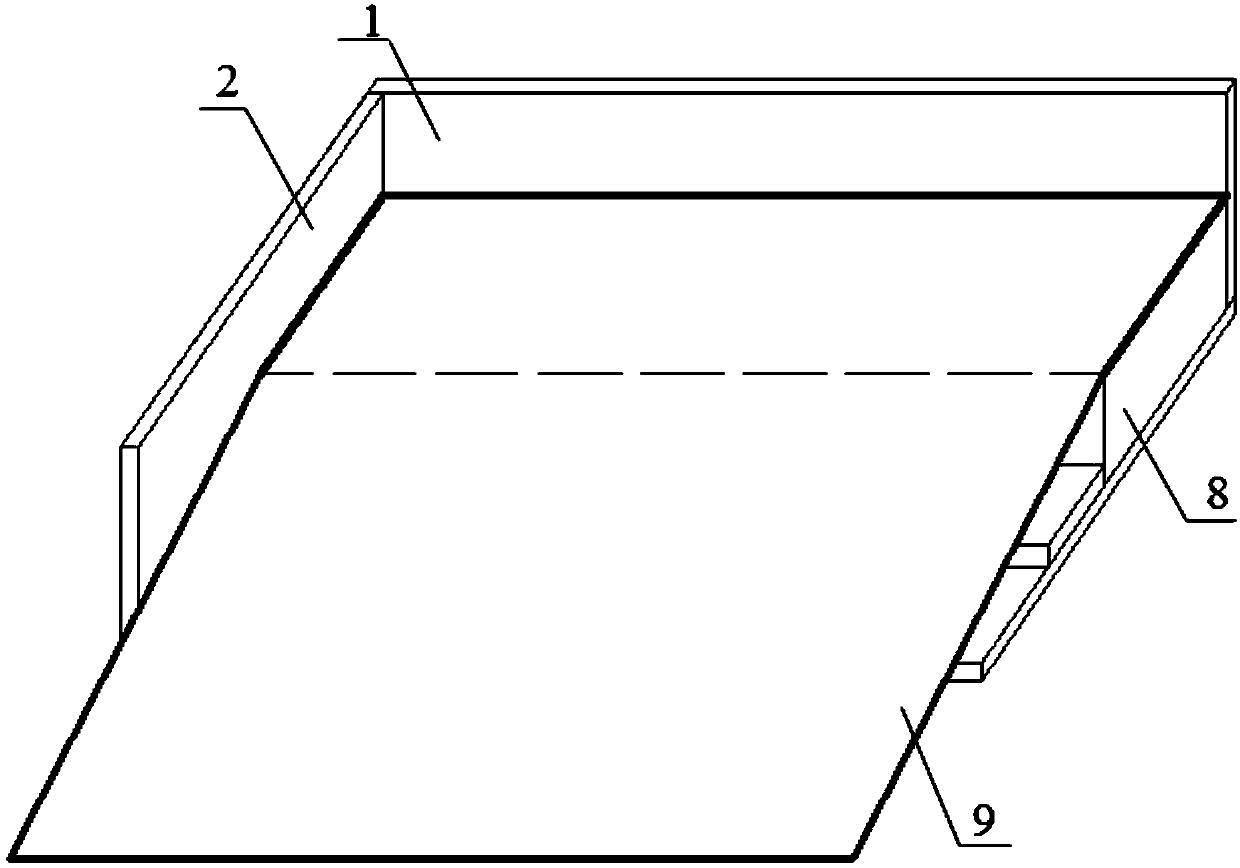

[0032] (1) One corner of the cuboid standard mold is close to the inner right angle clamped by the first vertical plate 1 and the second vertical plate 2 of the positioning mould;

[0033] (2) slide the sliding baffle plate 3 of the positioning mold along the chute 5 on the positioning mold base plate 6, so that the adjacent two sides of the sliding baffle plate 3 are respectively attached to the cuboid standard template 7 and the second vertical plate 2;

[0034] (3) The screw 4 is passed through the through hole and the chute 5 on the sliding baffle 3, and the screw 4 is tightened by using the nut at the bottom of the positioning mold base plate 6, so that the sliding baffle 3 is fixed on the base plate 6, and the positioning mold is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com