Bicycle gear shifter and bicycle

A bicycle and gear shifter technology, which is applied to bicycle accessories, bicycle gear shifting mechanisms, transportation and packaging, etc., can solve the problems of insufficient compact structure, poor linkage, complex structure, etc., so as to improve the reliability of shifting gears and reduce production costs. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

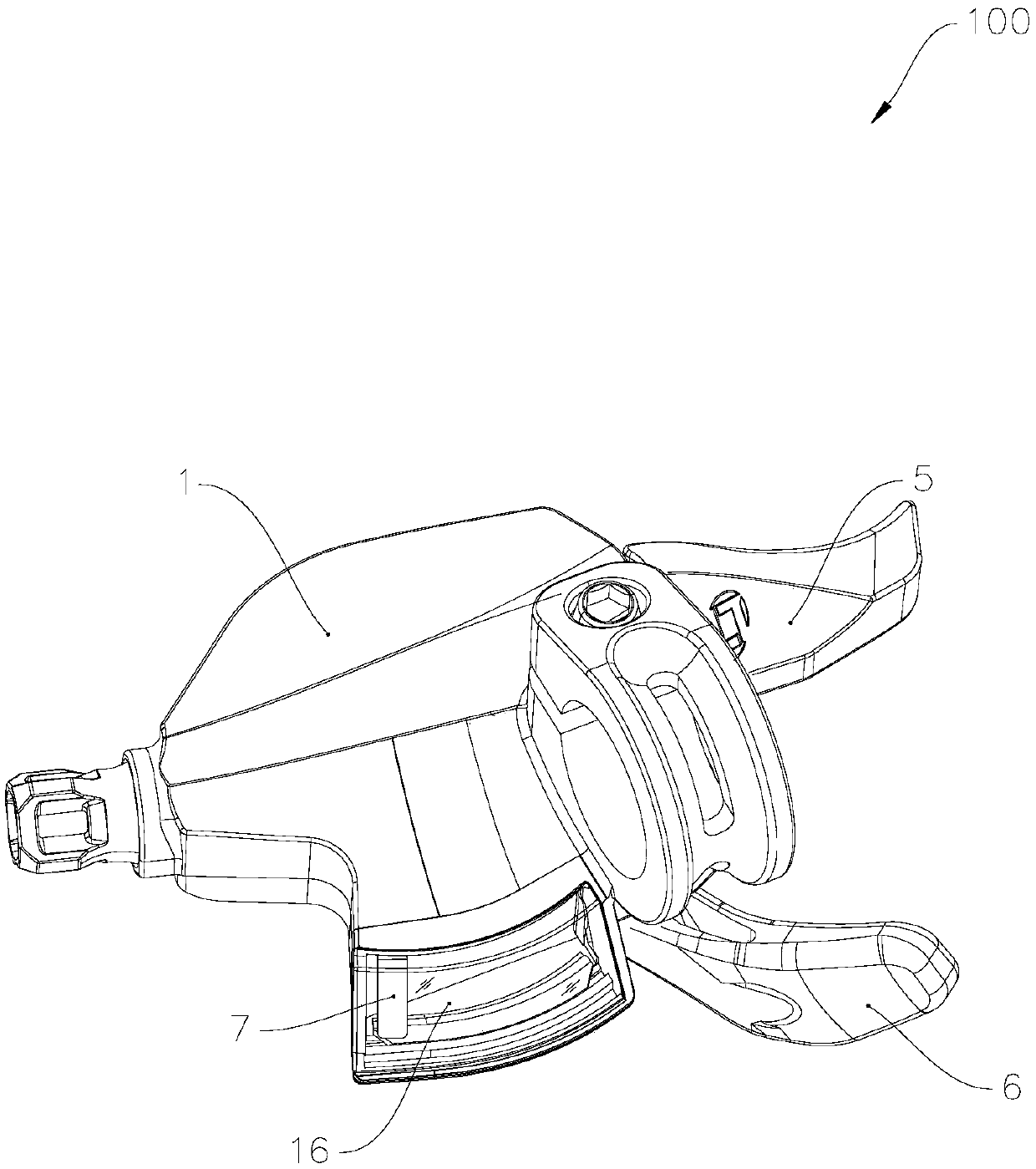

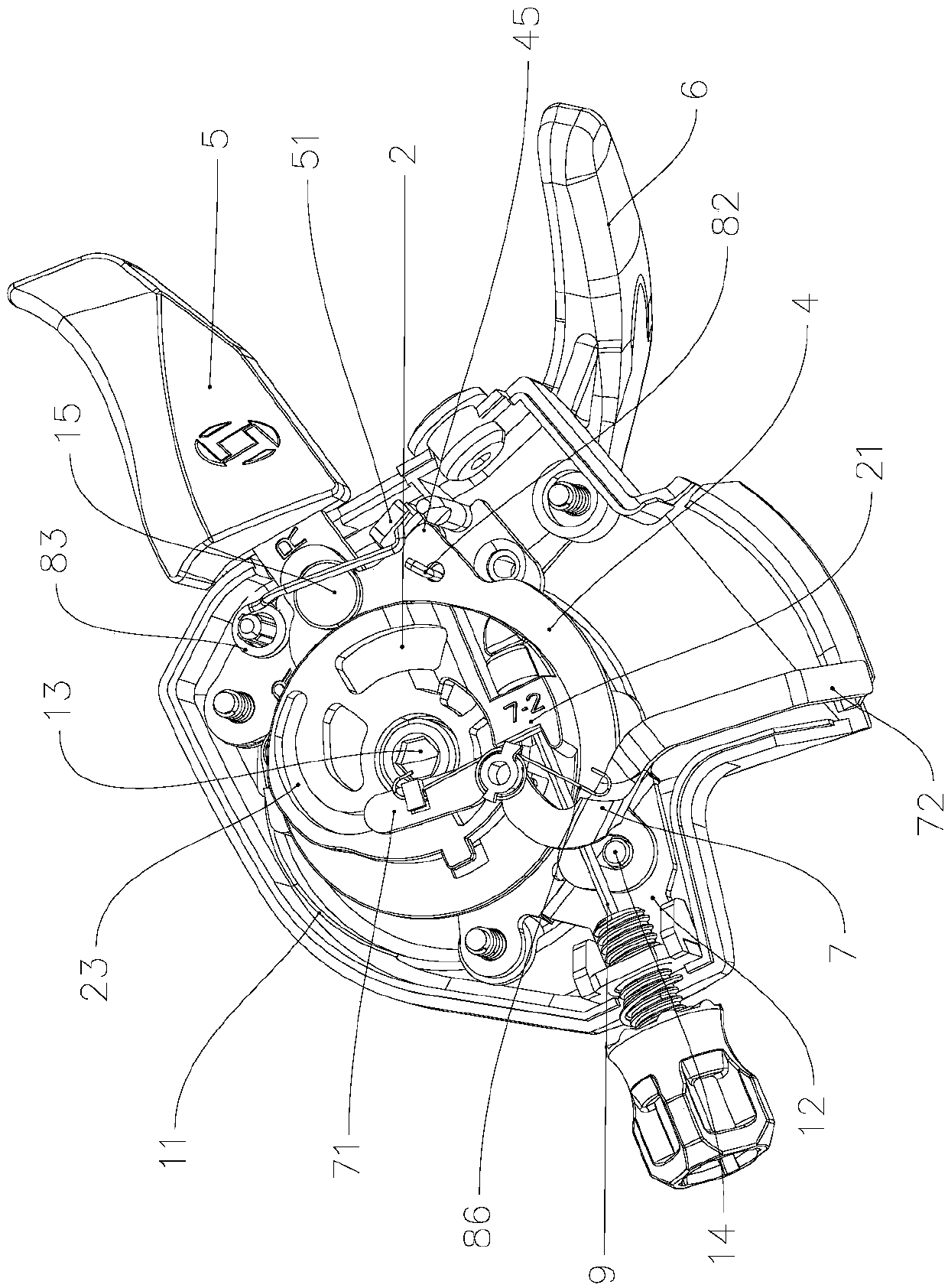

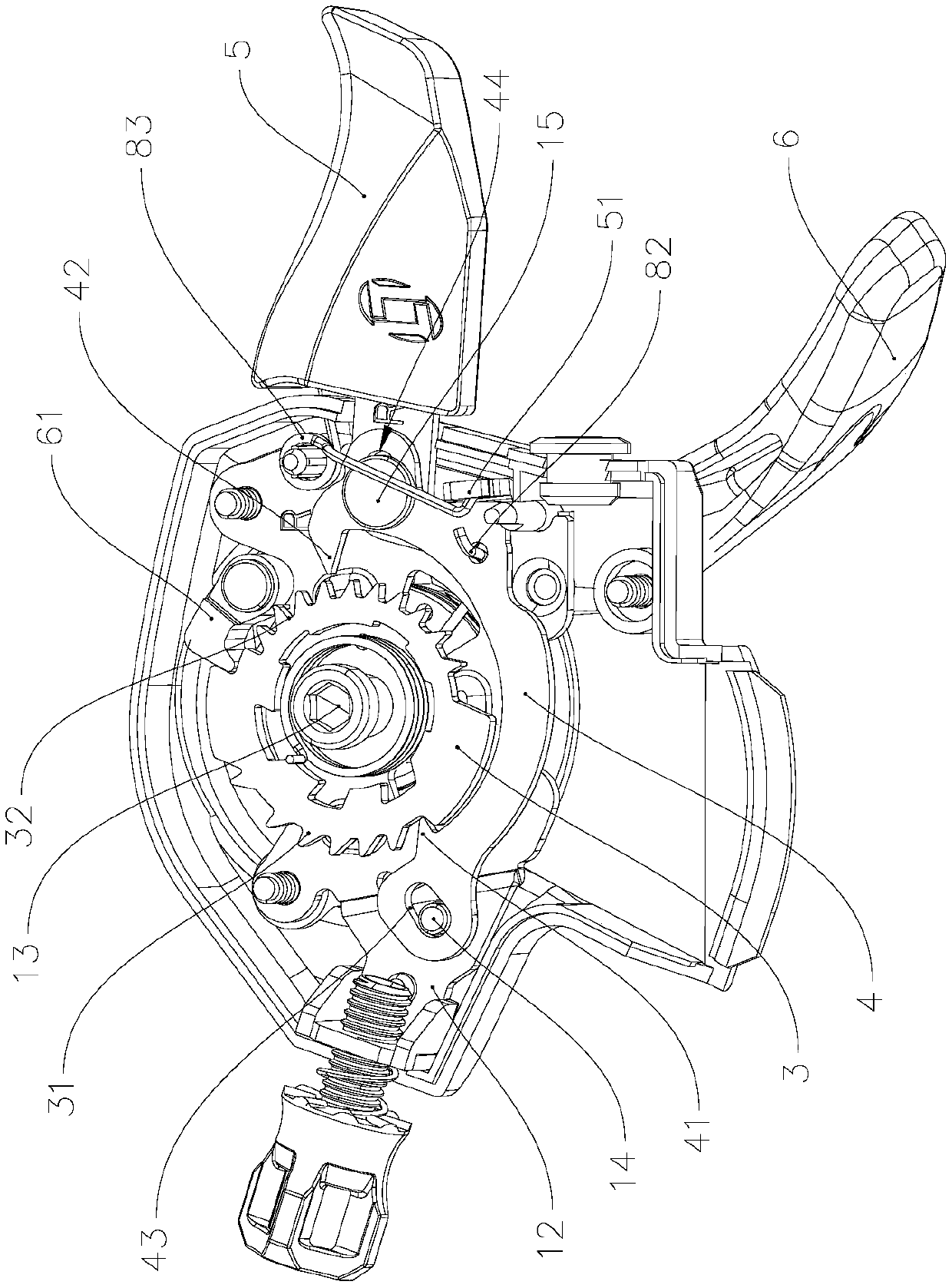

[0034]The bicycle includes a vehicle frame, a derailleur, a speed change line and a bicycle shifter 100. The derailleur is installed on the rear chainstay of the vehicle frame or in the middle of the vehicle frame, and the first end of the speed change line is connected with the derailleur.

[0035] refer to Figure 1 to Figure 3 , The bicycle shifter 100 includes a housing 1 , a winding member 2 , a ratchet 3 , a pawl member 4 , a release lever 5 , a push rod 6 and an indication member 7 . Wherein, the housing 1 is installed on the handle of the vehicle frame. The housing 1 includes an upper housing and a lower housing, and an accommodating cavity 11 is formed between the upper housing and the lower housing. A bracket 12 is fixedly installed on the lower housing, the bracket 12 is located in the receiving cavity 11 , and a rotating shaft 13 is arranged on the bracket 12 .

[0036] combine Figure 4 , the winding member 2 is sleeved on the rotating shaft 13 , and the winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com