Manual push hedge trimmer

A technology for hedge trimmers and trolleys, which is applied to equipment for trimming hedges, etc., can solve the problems of wide roads, inability to meet hedge trimming work on narrow roads, and small adjustment ranges, and achieves a high degree of automation, high trimming efficiency, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

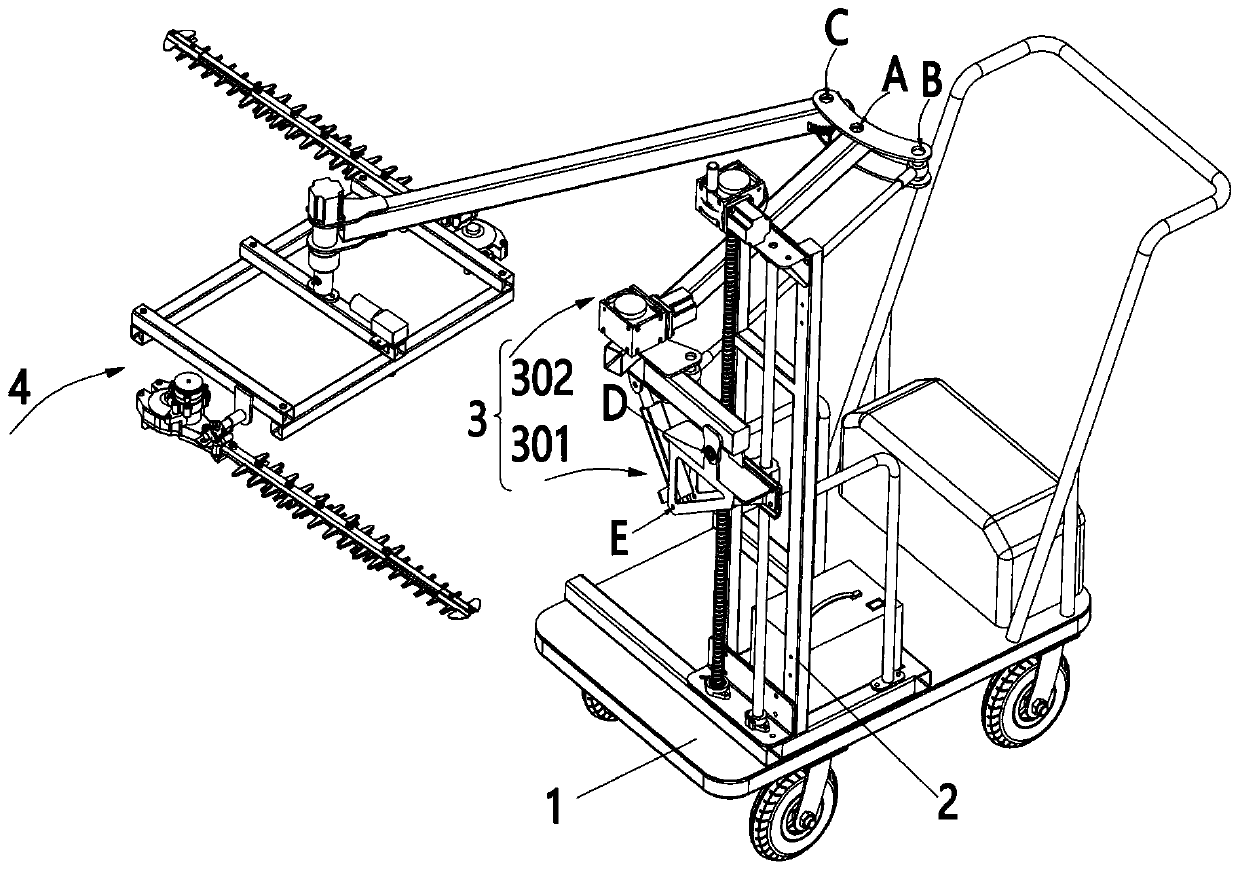

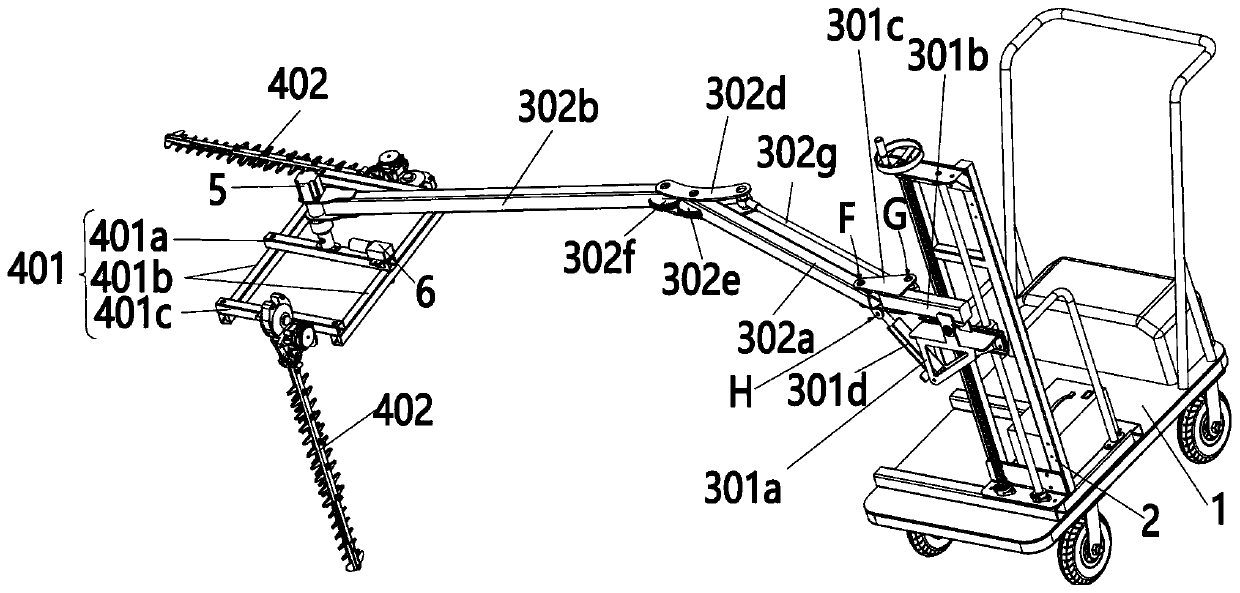

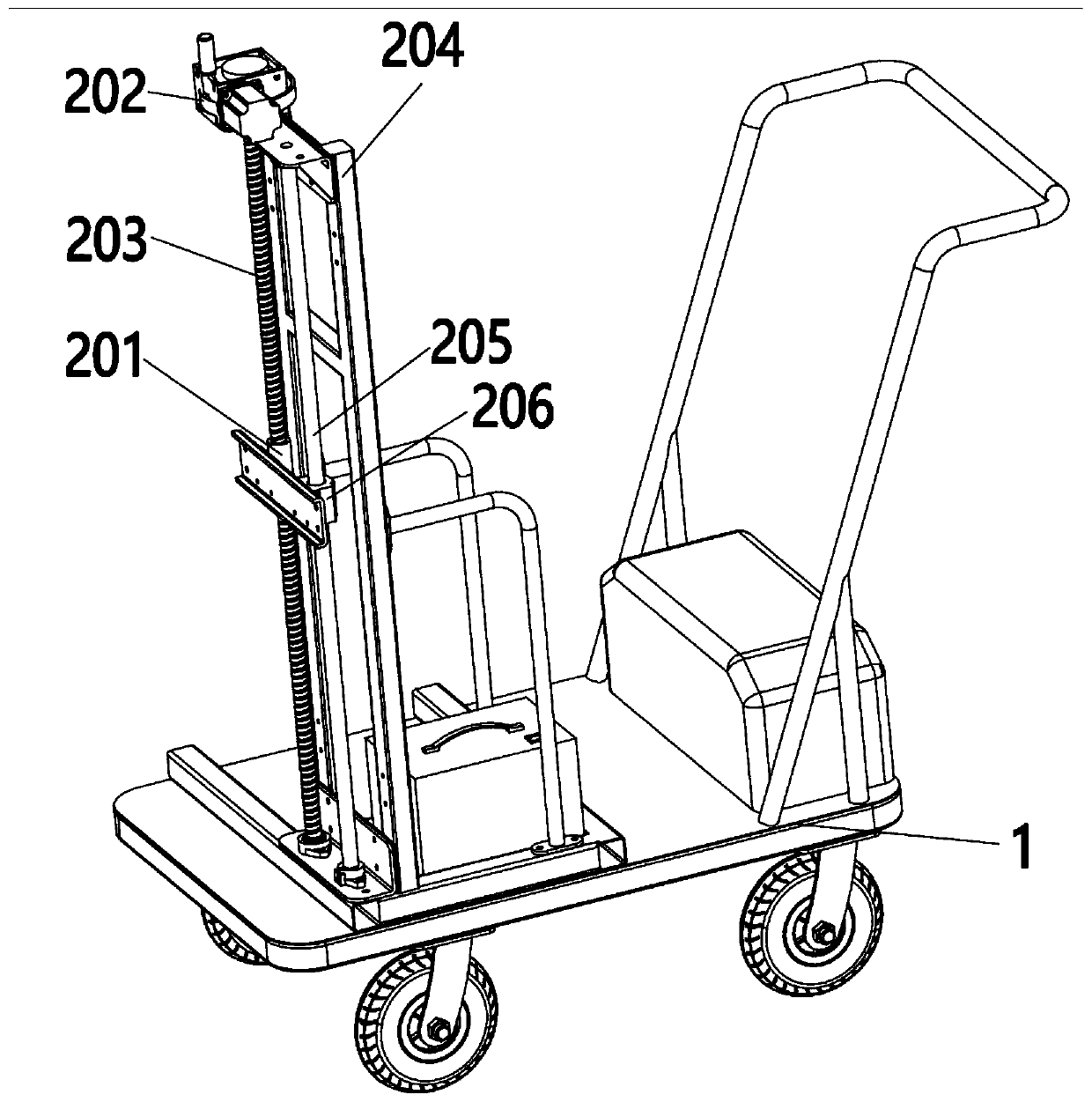

[0039] Such as Figure 1 to Figure 6 As shown, a hand push hedge trimmer includes a trolley 1, the trolley 1 is provided with a lifting mechanism 2, the lifting mechanism 2 includes a moving part 201, and the moving part 201 is provided with a ledge mechanism 3, and the ledge mechanism 3 includes a The mounting frame assembly 301 on the moving part 201 and the folding telescopic arm assembly 302 connected on the mounting frame assembly 301, the folding telescopic arm assembly 302 includes the active arm 302a and the driven arm 302b that are engaged with the end gears, and the driving arm 302a that drives the rotation The first motor 302c and the first connector 302d located at the gear meshing end, the active arm 302a is hinged on the first connector 302d through the hinge point A, the other end of the active arm 302a is hinged on the mounting frame assembly 301, the active arm 302a An auxiliary rod 302g is arranged on the side, one end of the auxiliary rod 302g is hinged on t...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that in order to further improve the stability of the hedge shears 402 during the pruning process, there are two drive pipes 602, including the active drive shaft 401ba connected to the second drive transmission assembly 6 and the active drive shaft 401ba in the active drive Driven by the shaft 401ba, the driven drive pipe 401bb rotates. A transmission connecting pipe 401c is provided between the active driving shaft 401ba and the driven driving pipe 401bb. The hedge shears 402 are pivotally connected to the connecting pipe 401c. Specifically, the end of the fixed pipe 401a The connecting pipe 401c includes a left connecting pipe 401c and a right connecting pipe 401c symmetrically arranged on both sides of the fixed pipe 401a, and the left connecting pipe 401c and the right connecting pipe 401c are pivotally connected with hedge shears 402, The symmetrical setting enables two hedge shears 402 to work at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com