Low-density high-strength heat-conducting gasket and preparation method thereof

A heat-conducting gasket, high-strength technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of increased battery weight, no obvious loss of mechanical properties, and restrictions on the wide application of electric vehicles, so as to improve thermal conductivity , excellent thermal conductivity and low density, the effect of small density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

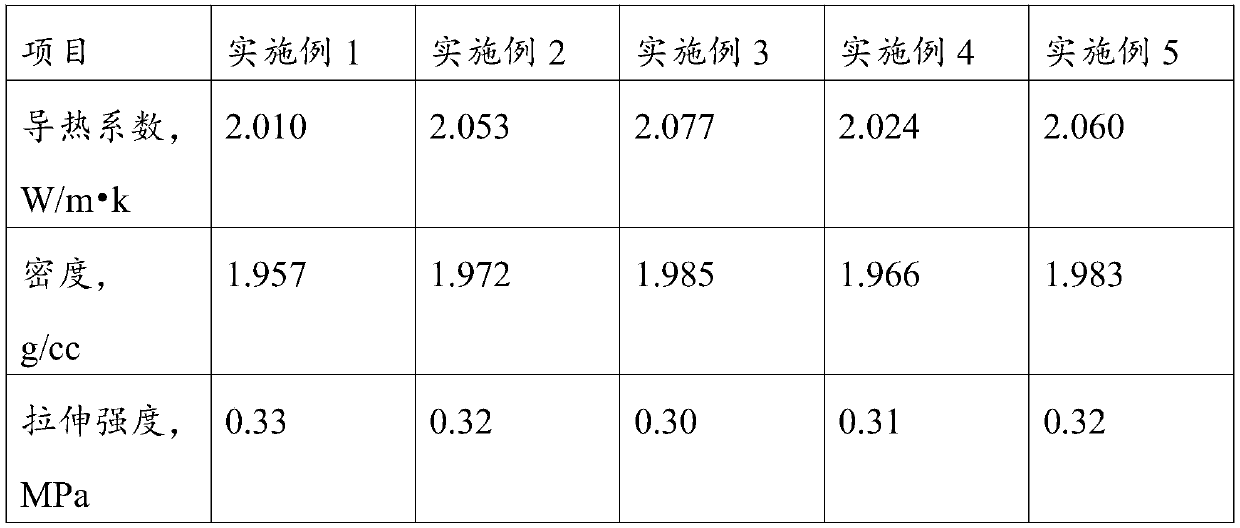

Examples

preparation example Construction

[0027] The preparation method of oleic acid-modified aluminum hydroxide in Examples 1 to 5 is:

[0028] Add 1000g of aluminum hydroxide to the stirring tank, and the stirring speed is 15-20rpm. After atomizing the oleic acid, spray it from the upper part of the stirring tank into the stirring tank. The spraying speed is controlled at 0.10-0.13g / min, and the spraying time is 30- 40min, then raise the temperature to 50~60℃, keep the temperature for 1.5~2 hours, cool to room temperature and discharge. The obtained powder is oleic acid-modified aluminum hydroxide.

Embodiment 1

[0030] A low-density and high-strength thermally conductive gasket, by weight, comprises the following components:

[0031] 100g of methyl silicone oil with a viscosity of 450mPa˙s, 10g of vinyl terminated silicone oil with a viscosity of 200mPa˙s and a vinyl content of 0.2wt%, 10g of vinyl silicone oil with a viscosity of 50000mPa˙s and a vinyl content of 0.3wt%, active hydrogen 5g methyl hydrogen-containing silicone oil with a content of 0.3wt%, 2g platinum catalyst, coupling agent γ-glycidyl ether oxypropyltrimethoxysilane KH-5603g, oleic acid modified aluminum hydroxide 600g, particle size 8~ 60 g of 15 μm alumina and 5 g of hydrogenated castor oil with a melting point of 85 to 88°C.

Embodiment 2

[0033] A low-density and high-strength thermally conductive gasket, by weight, comprises the following components:

[0034] 100g methyl silicone oil with a viscosity of 550mPa˙s, 20g vinyl terminated silicone oil with a viscosity of 100mPa˙s and a vinyl content of 0.3wt%, 15g of vinyl silicone oil with a viscosity of 100000mPa˙s and a vinyl content of 0.1wt%, active hydrogen Hydroxy-hydrogen silicone oil with a content of 0.5wt% 8g, platinum catalyst 5g, coupling agent methacryloyloxy functional group silane KH-5705g, oleic acid modified aluminum hydroxide 700g, particle size 15-30μm alumina 75g , 7 g of hydrogenated castor oil with a melting point of 85-88°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap