A kind of high viscosity protective film and preparation method thereof

A protective film and high-viscosity technology, which is applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of easy adhesion between the surface layer and the adhesive layer, and is not easy to peel off, so as to reduce the unwinding force, good anti-sticking and unwinding sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

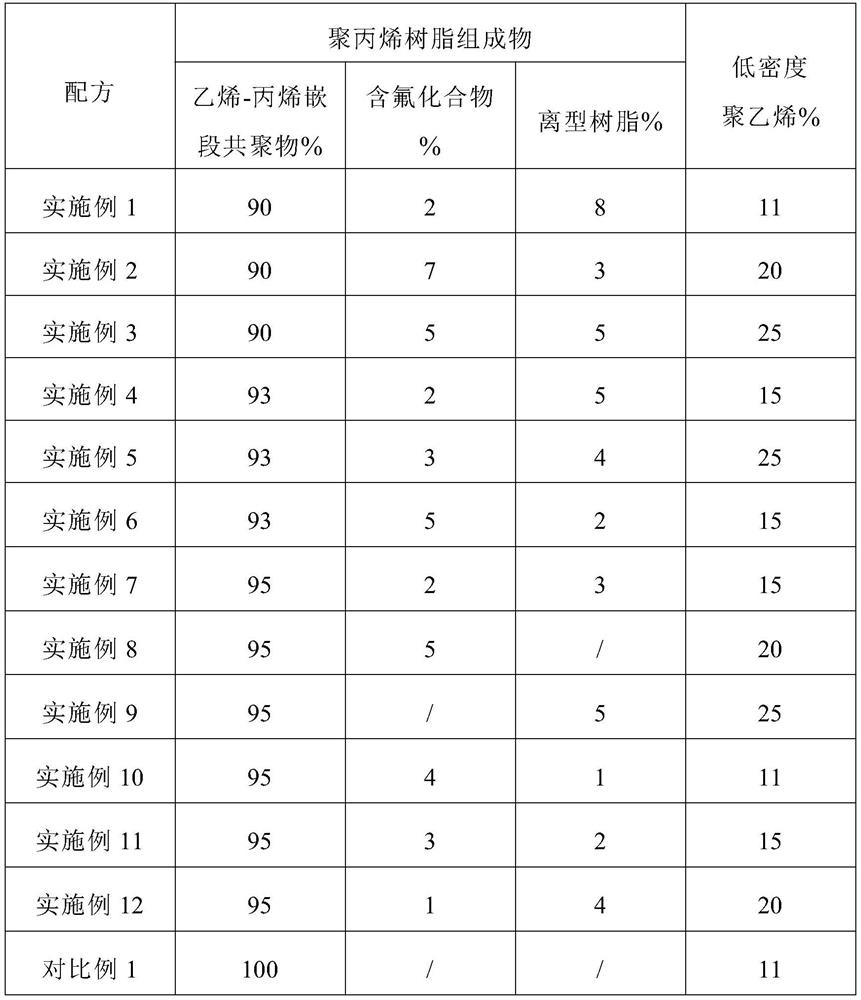

Embodiment 1

[0038] The high-viscosity protective film provided by the invention sequentially comprises a surface layer, a core layer and an adhesive layer.

[0039] The surface layer is compounded by polypropylene resin composition and low-density polyethylene at a ratio of 90.1%:9.9%. The polypropylene resin composition is 90% by weight of ethylene-propylene block copolymer, 2% by weight of fluorine-containing compound and 8% by weight of release resin, which are granulated through an extruder. The total weight of the ethylene-propylene block copolymer, the fluorine-containing compound and the release resin is 100%, and the low-density polyethylene accounts for 11% of the total weight of the ethylene-propylene block copolymer, the fluorine-containing compound and the release resin. The density of ethylene-propylene block copolymer is 0.90g / cm 3 , The melt index is 4.0g / 10min. Fluorochemicals are perfluoroalkyl acrylates. The release resin is a vinyl polymer chemically modified by styr...

Embodiment 2

[0044] As the high-viscosity protective film provided in embodiment 1, the difference is:

[0045]The surface layer is compounded by polypropylene resin composition and low-density polyethylene at a ratio of 83.3%:16.7%. The polypropylene resin composition is 90% by weight of ethylene-propylene block copolymer, 7% by weight of fluorine-containing compound and 3% by weight of release resin. The total weight of the ethylene-propylene block copolymer, the fluorine-containing compound and the release resin is 100%, and the low-density polyethylene accounts for 20% of the total weight of the ethylene-propylene block copolymer, the fluorine-containing compound and the release resin.

Embodiment 3

[0047] As the high-viscosity protective film provided in embodiment 1, the difference is:

[0048] The surface layer is composed of polypropylene resin composition and low-density polyethylene at a ratio of 80%:20%. The polypropylene resin composition is 90% by weight of ethylene-propylene block copolymer, 5% by weight of fluorine-containing compound and 5% by weight of release resin. The total weight of the ethylene-propylene block copolymer, the fluorine-containing compound and the release resin is 100%, and the low-density polyethylene accounts for 25% of the total weight of the ethylene-propylene block copolymer, the fluorine-containing compound and the release resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com