Flexible electricity feeding device based on continuous anode aluminum electrolysis cell

An electrolytic cell and anode aluminum technology, applied in the field of aluminum electrolysis, can solve the problems of reduction of conductive area, fluctuation of electrolytic cell voltage, and influence on the stability of electrolytic cell, and achieve the effect of improving stability, reducing stability, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

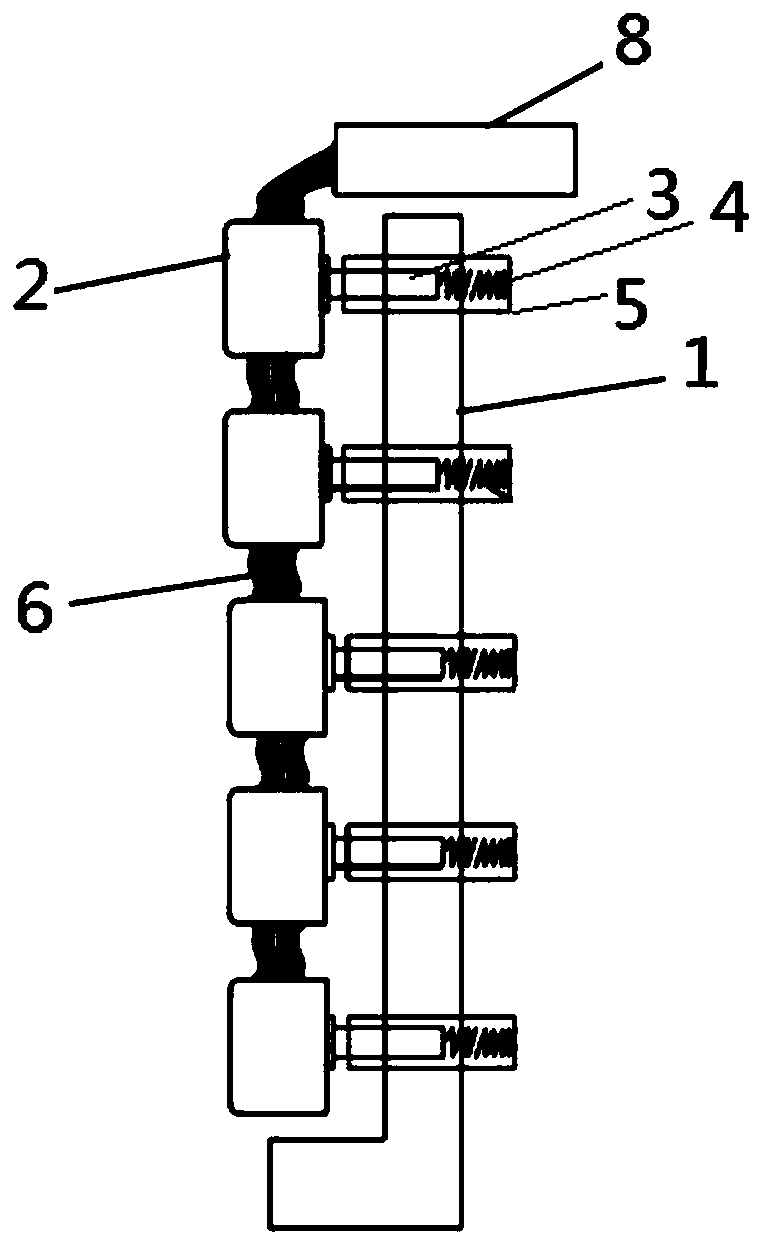

[0022] Such as Figure 1-3 As shown, a flexible power feeding device based on a continuous anode aluminum electrolytic cell includes: several conductive components arranged sequentially from top to bottom, and a fixing frame 1;

[0023] The conductive component includes: a conductive body 2, a jacking rod 3, an elastic device 4 and a support body 5; preferably, there are two or more conductive components;

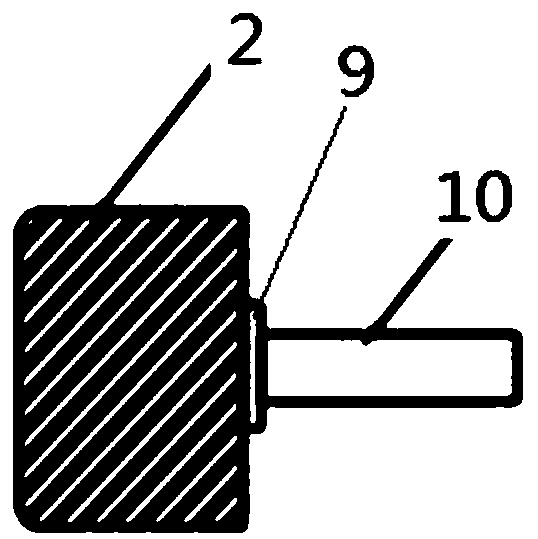

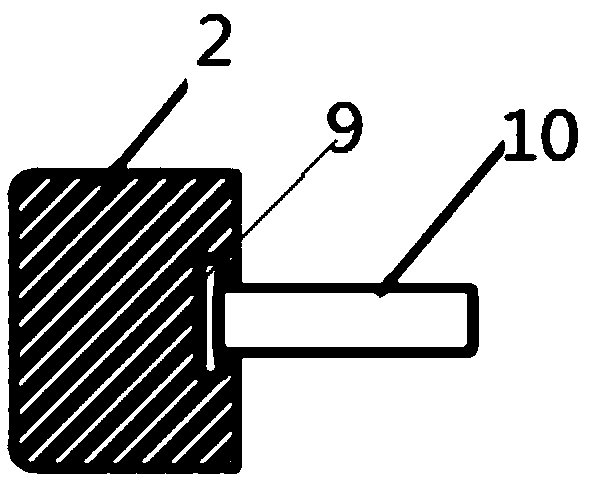

[0024] The conductor 2 is a cuboid or a cube, and its size depends on the actual situation. It is made of a material with good conductivity, which can be aluminum or copper;

[0025] The jacking rod includes a rectangular connecting block 9 and a horizontal cylindrical rod 10 connected to one end of the connecting block; one side wall of the conductor 2 and one end of the jacking rod connecting block 9 are fixed by welding, threaded conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com