Manufacturing method of alpaca wool/superfine wool 50/50 sirospun blended yarn

A production method and alpaca wool technology, applied in the field of spinning, can solve the problems of reducing the hairiness of the finished yarn, and achieve the effects of good heat preservation and moisture absorption, plump and smooth hand feeling, and good drape feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

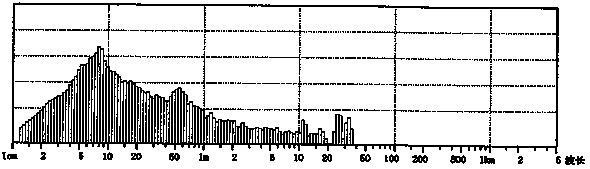

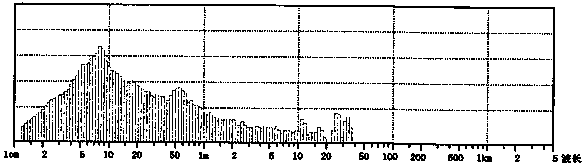

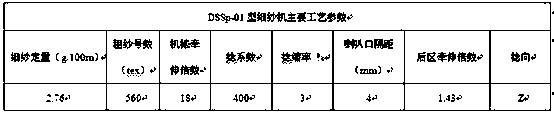

Image

Examples

Embodiment

[0029] 1. Preparation before spinning

[0030] The pre-spinning preparatory work can be summarized as: length measurement → wool trimming → shearing → weighing → calculation → batching → pre-wetting.

[0031] Cotton spinning equipment is used. Alpaca is provided by Taiyuan Ronghuang Alpaca Co., Ltd. The raw material has been spun into slivers. The ultra-fine wool is cotton-type length, 38mm. In order to blend with ultra-fine wool, the alpaca must first be measured. Length, the measured length of the main body of alpaca is 172.73mm, and then the hand-pulled finishing is carried out, and after finishing into a fiber bundle with one end even, cut it into 38mm with scissors, weigh it after cutting, and calculate the spinning according to the weight of the fiber. After adjusting the amount of yarn auxiliary agent, prepare the material and pre-wet the fiber for 24 hours.

[0032] The pre-moistening ratio of alpaca and superfine wool is the same, and hair oil agent: 0.8% (density 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com