Hole type mechanical interlocking building blocks with steel reinforcements and construction method of perforated mechanical gripping building blocks

A hole-type, occlusal technology, applied to building components, walls, buildings, etc., can solve problems such as poor thermal insulation effect and cracks in blocks, and meet the bonding requirements and waterproof, sound insulation, thermal insulation performance , Enhanced sound insulation and heat insulation performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

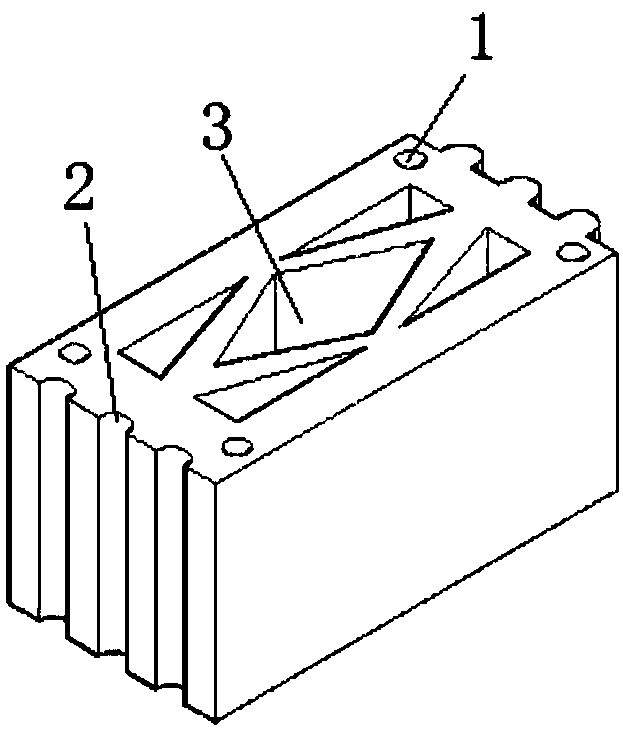

[0044] Such as Figure 3-7 As shown, the present invention provides a kind of mechanically interlocking block with reinforced holes, including:

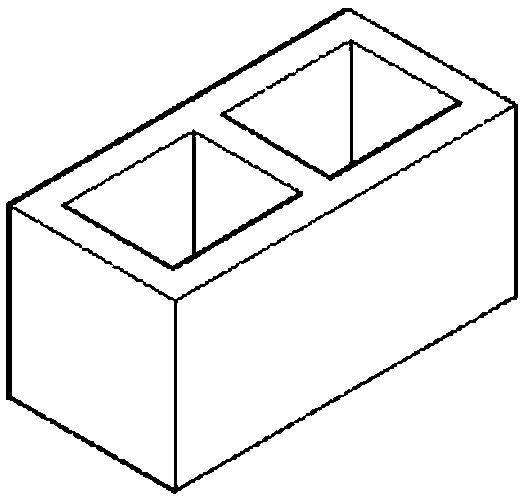

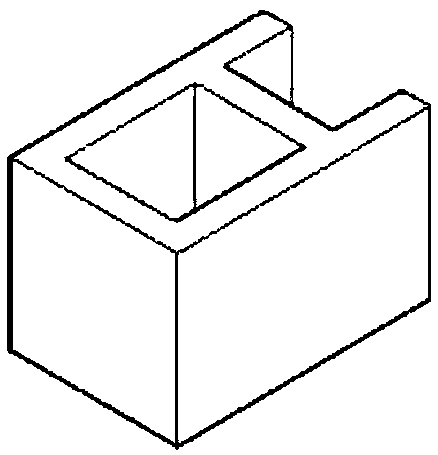

[0045] rectangular blocks;

[0046] at least two cavities 3 in the rectangular blocks;

[0047] Rebar holes 1 respectively provided on the four corners of the blocks;

[0048] Vertical steel bars 5 inserted in the steel bar holes;

[0049] The protruding groove 2 arranged on one edge line of the block along the width direction, the concave groove 2 arranged on the other edge line of the block along the width direction, the protruding groove 2 of a block The mouth is engaged with the concave groove and groove of another block, and there is a gap between the engaged protruding groove a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com