Ignition coil dwell control

An ignition coil and dwell time technology, applied in ignition controllers, spark ignition controllers, engine ignition, etc., can solve the problems of increasing the overall wear of the ignition system, increasing the size of the spark plug gap, increasing the wear of the ignition system, etc. Heat generation and aging, wear rate prolongation, effect of reducing component stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

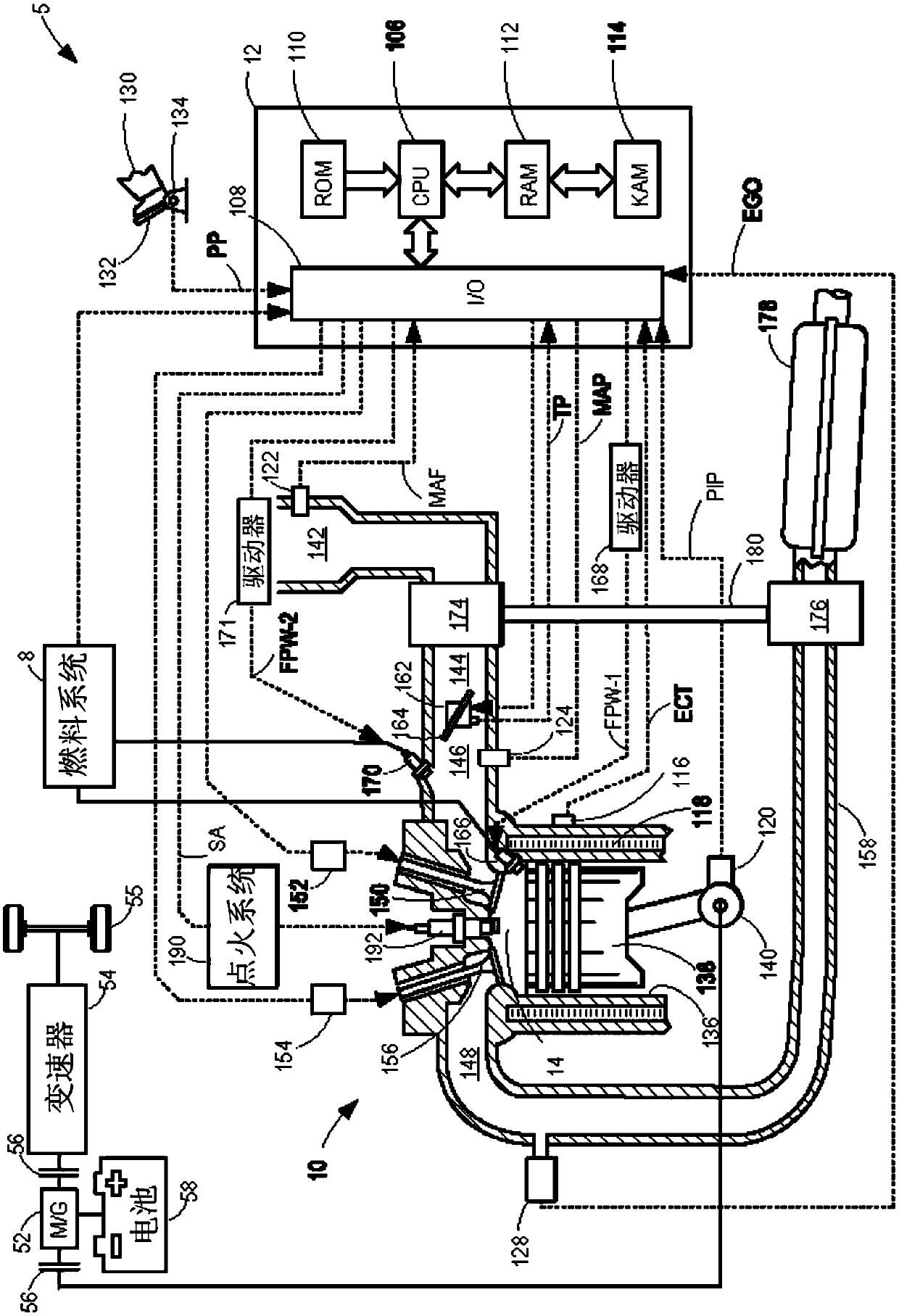

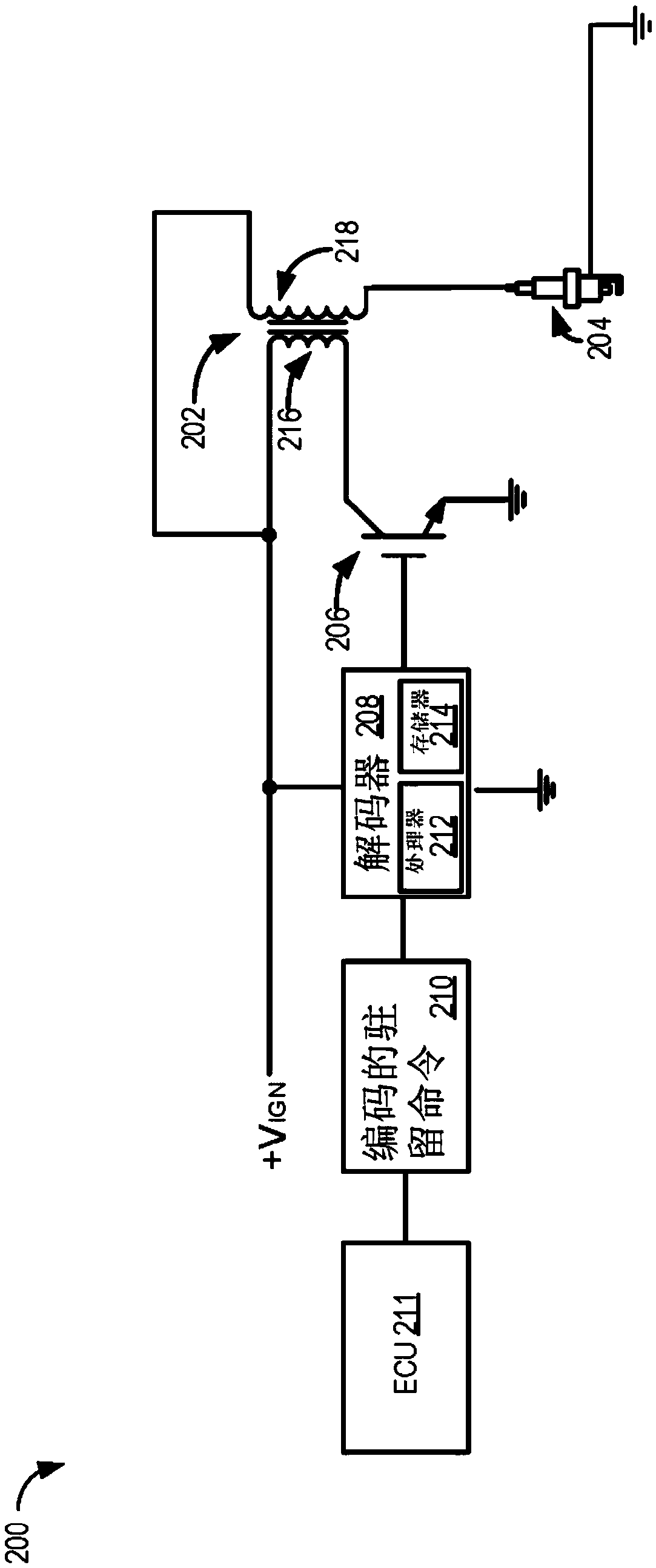

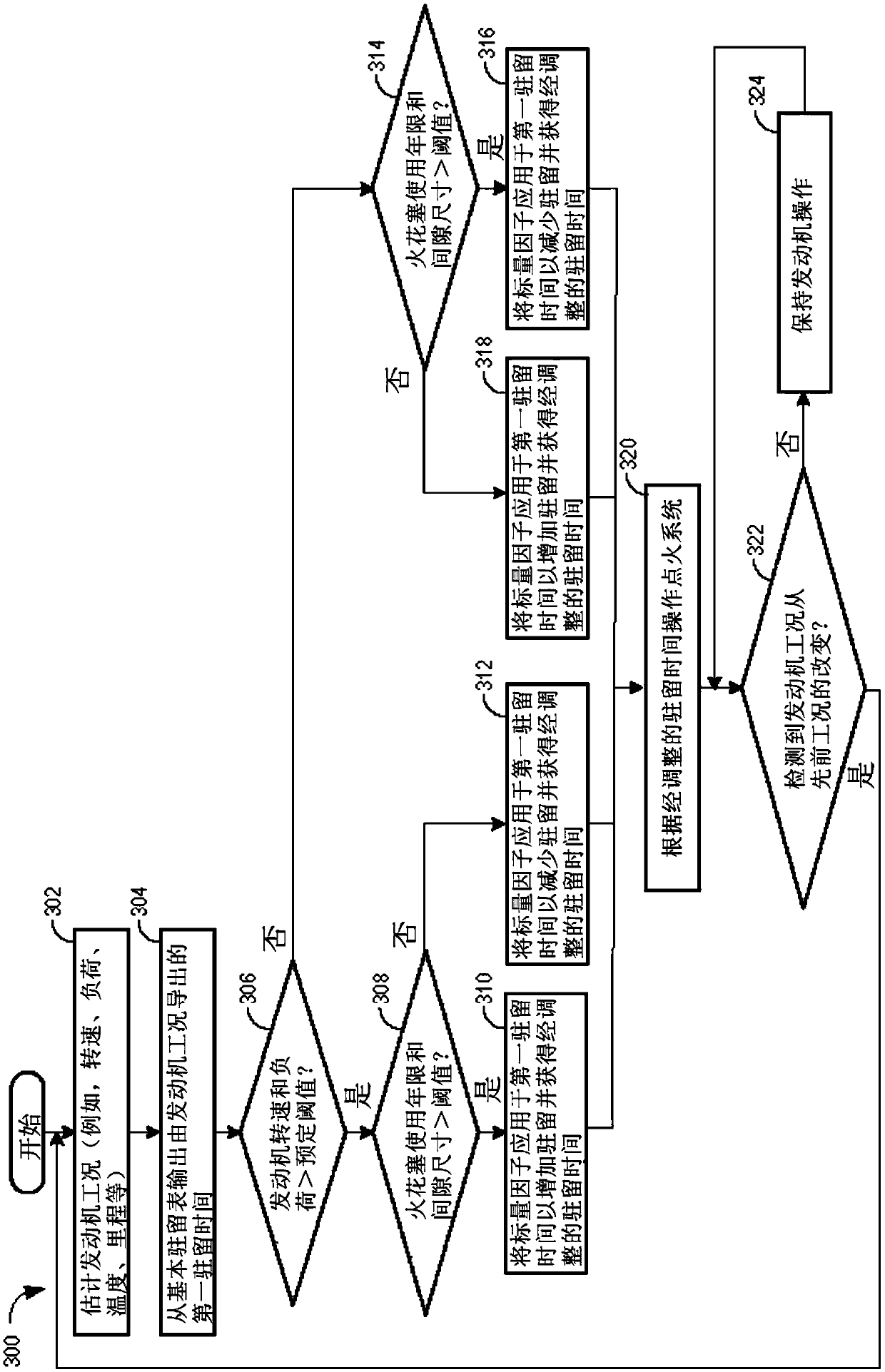

[0012] The following description relates to control of internal combustion engines such as figure 1 A system and method for dwell time in an ignition system of an example engine system. Optimum engine performance can be achieved by: when the engine is operating at high rpm and high load conditions, by figure 2 High pressure spark energy is provided in the ignition system shown) for higher dwell, while for engines operating at low rpm and low load conditions, dwell is increased to provide longer spark duration. The provided baseline dwell amount may be obtained from a base dwell look-up table included in the vehicle's control module. The baseline dwell time may additionally be calibrated to be proportional to spark plug condition (eg, age and gap size between spark plug electrodes). The spark plug gap size can be calculated based on accumulated mileage information, electrode material, and the geometry of the spark plug assembled in the ignition system. Based on the calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com