Multi-machine interconnecting waste steam and waste heat recovery system

A technology of waste heat recovery and multi-machine interconnection, which is applied in heating systems, hot water central heating systems, applications, etc., can solve problems such as insufficient heat supply, impact on energy saving effects, and the temperature of residents' homes cannot meet the requirements, so as to improve Energy-saving effect and effect of improving heating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

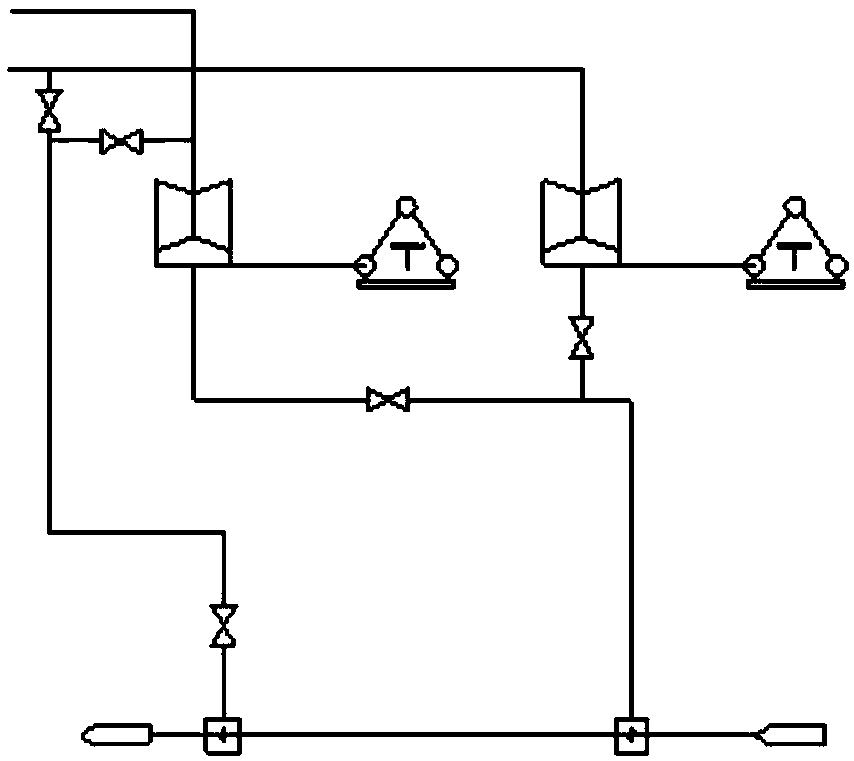

[0017] Implementation mode 1: dual-machine interconnection pre-condenser waste steam waste heat recovery heating system, such as figure 1 shown.

[0018] The heating system using pre-condenser waste steam waste heat recovery is also called high back pressure system. The unit operates with elevated back pressure, and uses the exhausted steam to directly enter the pre-condenser to heat the return water of the heating network to an appropriate temperature.

[0019] The exhaust steam outlet pipe (3) of the 1# large steam turbine unit and the exhaust steam outlet pipe (4) of the 2# large steam turbine unit are connected to each other, and the exhaust steam (exhaust steam of the low-pressure cylinder) of the two large steam turbine units is integrated to form a large steam turbine unit Exhaust steam leads to the shared pipeline (7). The exhaust steam outlet pipe (3) of the 1# large steam turbine unit and the exhaust steam outlet pipeline (4) of the 2# large steam turbine unit are ...

Embodiment approach 2

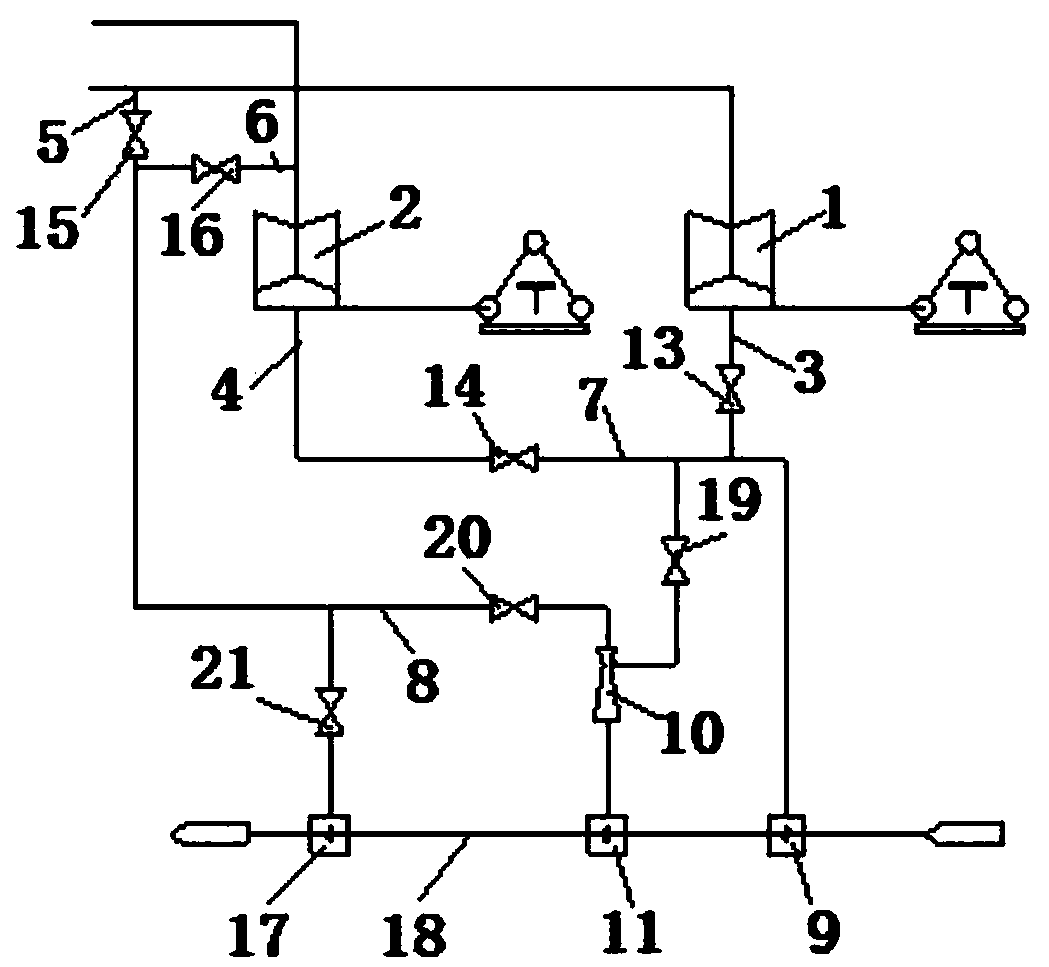

[0026] Implementation Mode 2: A heat supply system for recovery of waste heat from waste steam of dual-machine interconnected steam generators, such as figure 2 shown.

[0027] The exhaust steam outlet pipe (3) of the 1# large steam turbine unit and the exhaust steam outlet pipe (4) of the 2# large steam turbine unit are connected to each other, and the exhaust steam (exhaust steam of the low-pressure cylinder) of the two large steam turbine units is integrated to form a large steam turbine unit Exhaust steam leads to the shared pipeline (7). The exhaust steam outlet pipe (3) of the 1# large steam turbine unit and the exhaust steam outlet pipeline (4) of the 2# large steam turbine unit are respectively equipped with exhaust steam pipeline valves (13) and valves (14). The common pipe (7) leading out the exhaust steam of the large steam turbine unit is connected to the steam side of the pre-condenser.

[0028] The steam supply and extraction pipeline (5) of the 1# large steam...

Embodiment approach 3

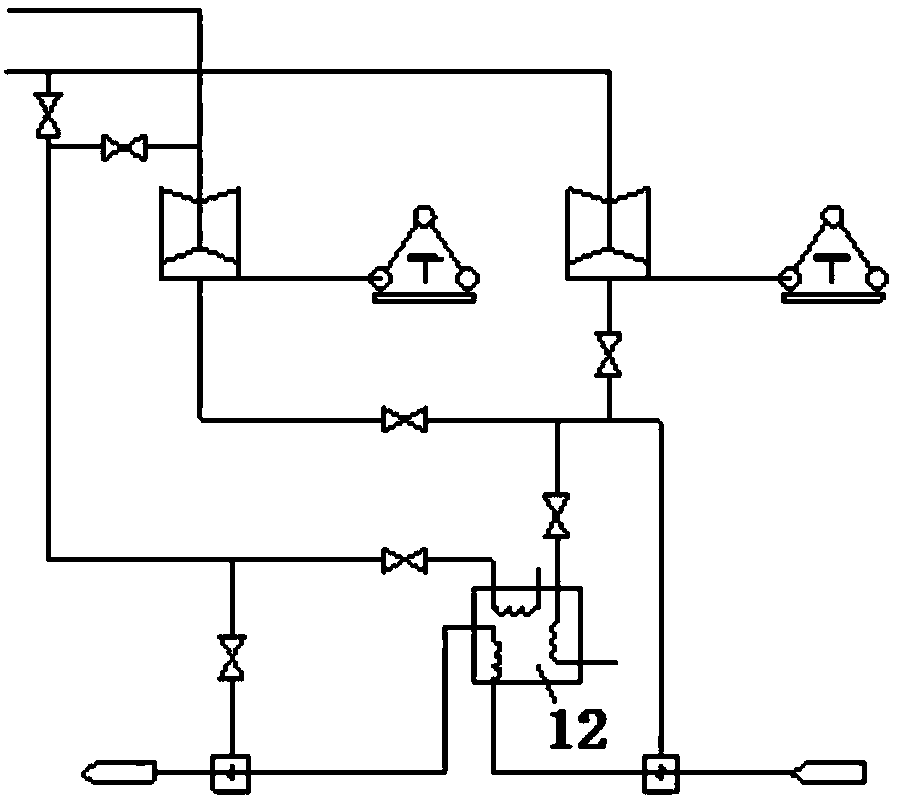

[0035] Implementation Mode 3: Dual-machine interconnected heat pump exhaust steam waste heat recovery heating system, such as image 3 shown.

[0036] The exhaust steam outlet pipe (3) of the 1# large steam turbine unit and the exhaust steam outlet pipe (4) of the 2# large steam turbine unit are connected to each other, and the exhaust steam (exhaust steam of the low-pressure cylinder) of the two large steam turbine units is integrated to form a large steam turbine unit Exhaust steam leads to the shared pipeline (7). The exhaust steam outlet pipe (3) of the 1# large steam turbine unit and the exhaust steam outlet pipeline (4) of the 2# large steam turbine unit are respectively equipped with exhaust steam pipeline valves (13) and valves (14). The common pipe (7) leading out the exhaust steam of the large steam turbine unit is connected to the steam side of the pre-condenser.

[0037] The steam supply and extraction pipeline (5) of the 1# large steam turbine unit and the steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com