Reinforcing base for box-type transformer station

A box-type substation and bottom plate technology, which is applied to the details of substation/switch layout, electrical components, and anti-seismic equipment, can solve the problems of box-type substations shaking and dumping, and the vibration amplitude is large. Strong connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

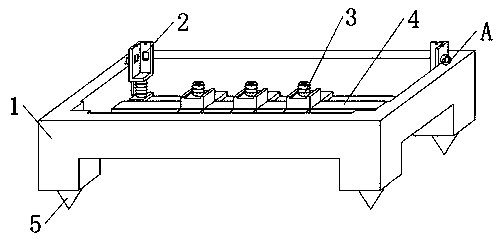

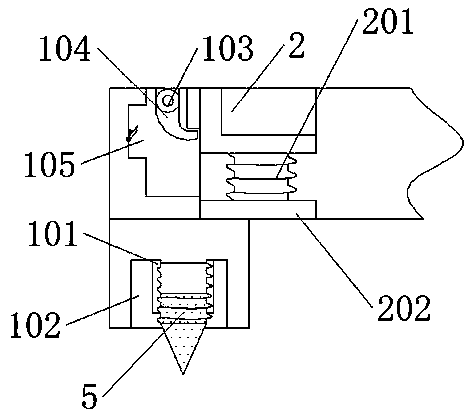

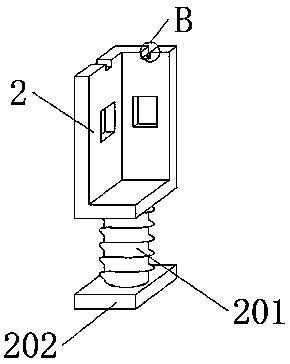

[0025] See figure 1 Attached Image 6 , A reinforced base for a box-type substation, including: the reinforced base for a box-type substation includes a frame 1, an adjusting fixed column 101, a support block 102, a rotating shaft 103, a buckle plate 104, a slide 105, a supporting card plate 2, a spring Block 201, bottom plate 202, sliding plate 203, connecting hole 204, bearing block 3, spring column 301, bearing plate 302, bearing column 4 and bottom cone 5. The bottom four corners of frame 1 are integrally provided with support blocks 102, and support blocks 102 The top of the middle part is welded with an adjusting and fixing column 101, and the middle of the bottom of the adjusting and fixing column 101 is screwed with a bottom cone 5. The bottom side of the left and right ends of the inner wall of the frame 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com