Apparatus for manufacturing grilled seaweed and method for manufacturing grilled seaweed

A manufacturing method and technology for manufacturing equipment, which can be applied to roasters/barbecue grids, roasting, food ovens, etc., and can solve problems such as reducing microbiological safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

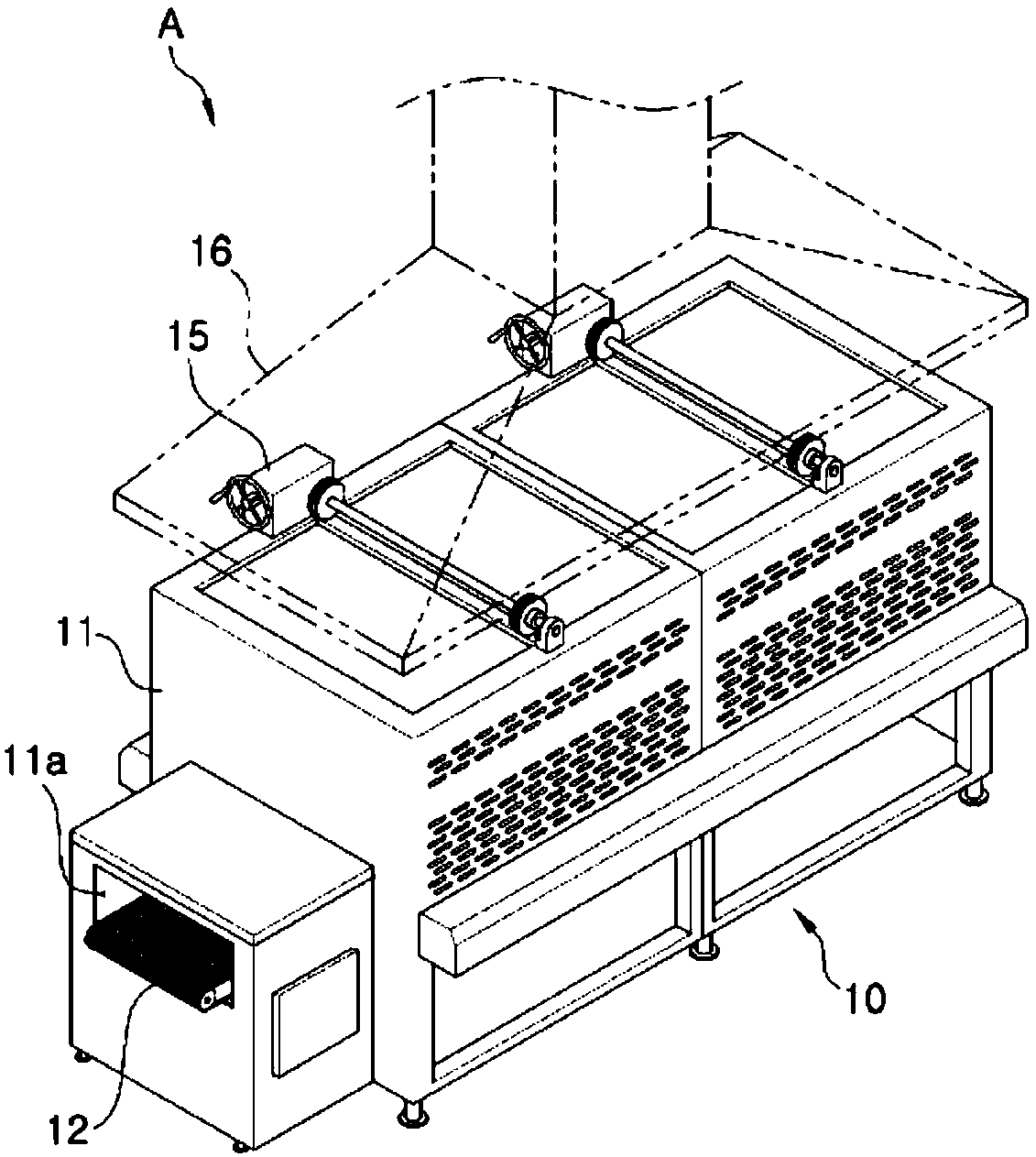

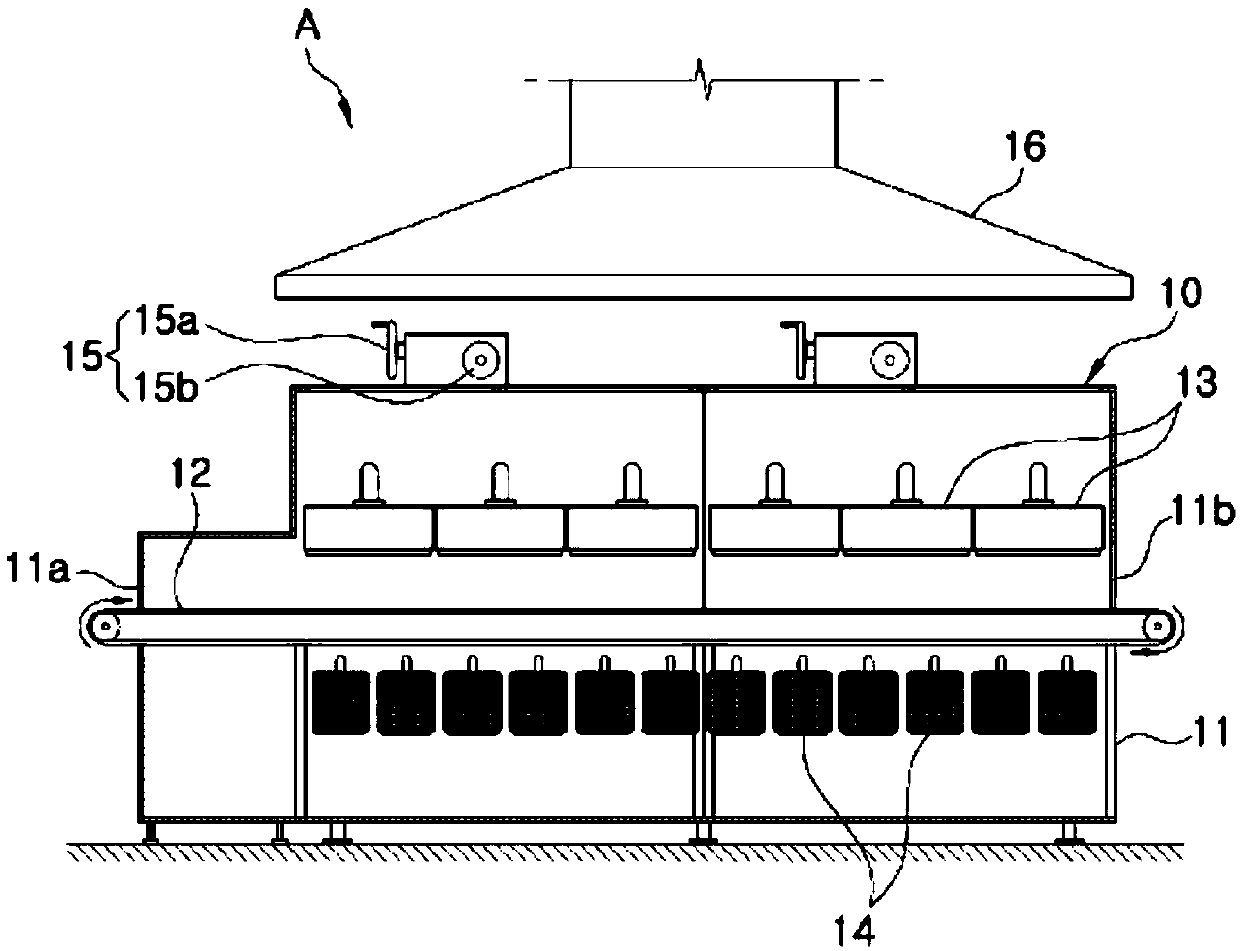

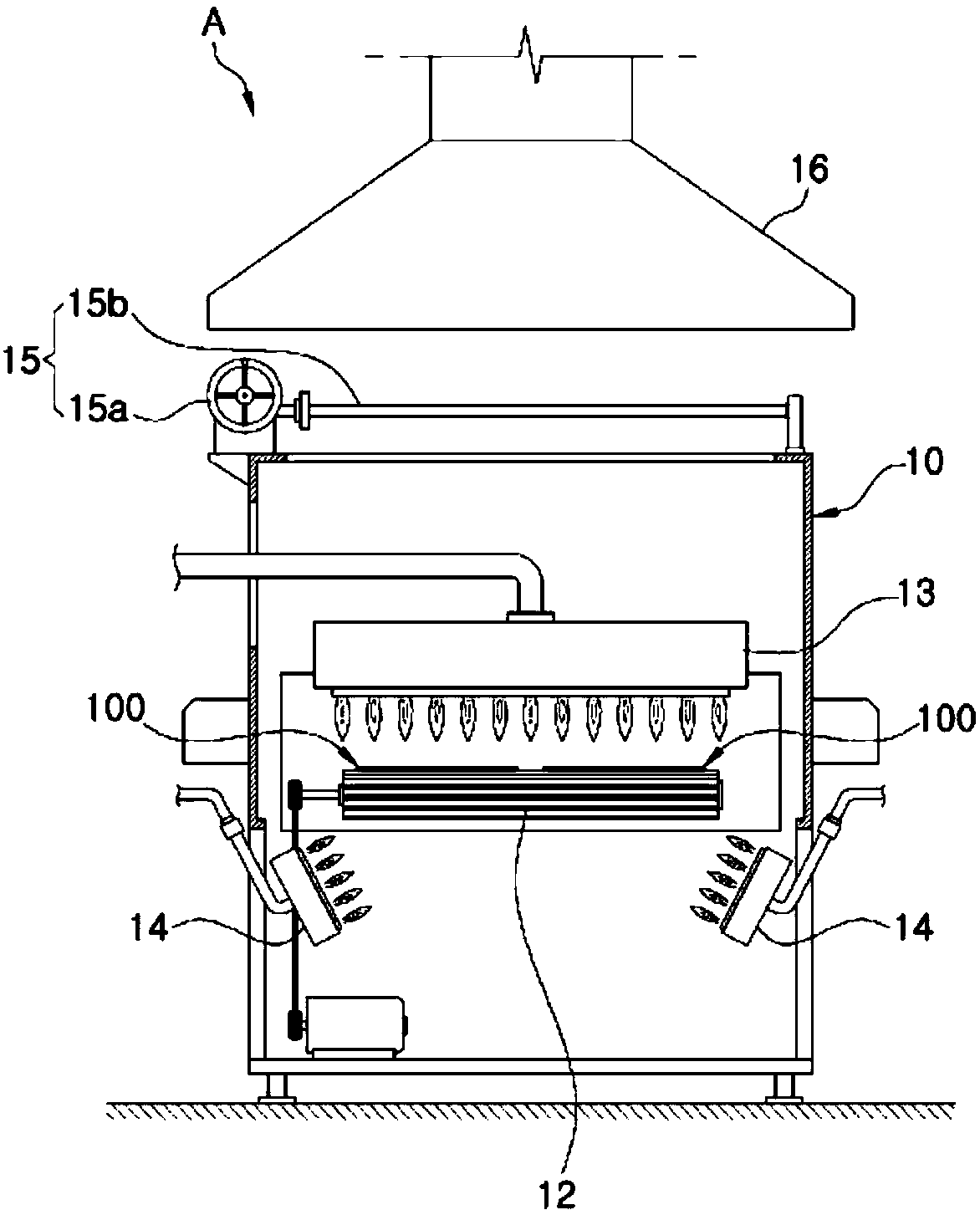

Image

Examples

Embodiment 1

[0093] The manufacture of embodiment 1-roasted seaweed

[0094] The dried nori kept at a temperature of -5°C was sorted by an image sorter, and then input into an electric oven to preliminarily bake the nori at a temperature of about 300°C for 1 second. After the preliminarily roasted nori was coated with a mixture of corn oil and sesame oil at a ratio of 8:2 through a sponge roller, the nori moistened with oil was seasoned with salt. After that, the seasoned nori is fed into a roasting unit equipped with a heating source using gas that discharges actual flames above and below, and then the nori is secondarily roasted for 6 seconds (about 700° C.) with a flame. The second-baked nori is input into the oiling unit that can be oiled, and the mixed oil of sesame oil and perilla oil at a ratio of 1:1 is applied to the surface of the nori through the nozzle to produce seasoned nori.

Embodiment 2

[0095] Example 2 - Evaluation of Microbiological Safety of Roasted Nori

[0096]Raw seaweed, seasoned seaweed baked by conventional electric oven (CJ natural seaweed is also called traditional seasoned seaweed) and seasoned / baked seaweed made in Example 1 (called seasoned / roasted seaweed) The microbiological safety of baked seaweed) was evaluated.

[0097] Specifically, a standard agar medium and a saline solution were prepared in a sterilized state to check the total bacterial count, and raw nori, conventional seasoned nori and seasoned / roasted nori kept at a temperature of 3°C were used as sterile State samples. 25 grams of each sample was placed in a sterile package and diluted at a rate of 10 times by adding 225 grams of sterile saline solution. After homogenizing each sample with a stomacher, it was further diluted by placing each sample into a test tube containing 9 ml of sterile saline solution. Diluted samples were distributed in 1 ml on petri dishes and in 15 ml on...

Embodiment 3

[0101] Example 3 - Evaluation of the functional qualities of seasoned / roasted nori

[0102] Functional quality was evaluated by simultaneously providing traditional seasoned nori and seasoned / roasted nori to 79 middle-aged (25-49 years old) housewives, and the results were obtained on a scale of 1 to 5 according to preference and property.

[0103] As a result, the average overall preference for traditional seasoned nori was 3.41, and the average overall preference for seasoned / roasted nori was 3.84. Therefore, it was noted that the overall preference for seasoned / roasted nori was high. In addition, the overall preference rate for traditional seasoned nori was 22.8%, while that for seasoned / roasted nori was 77.2%. Therefore, it was noted that the overall preference for seasoned / roasted nori was very high (see Table 2).

[0104] In particular, the seasoned roasted nori had significantly improved taste preference, texture preference, aftertaste preference, oily taste preferenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com