Hydraulic drive

A hydraulic and facility technology, applied in the direction of fluid pressure actuation devices, mechanical equipment, engine components, etc., can solve the problems of complexity, large flow loss, long flow path, etc., to achieve low flow loss, minimized heat input, high speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

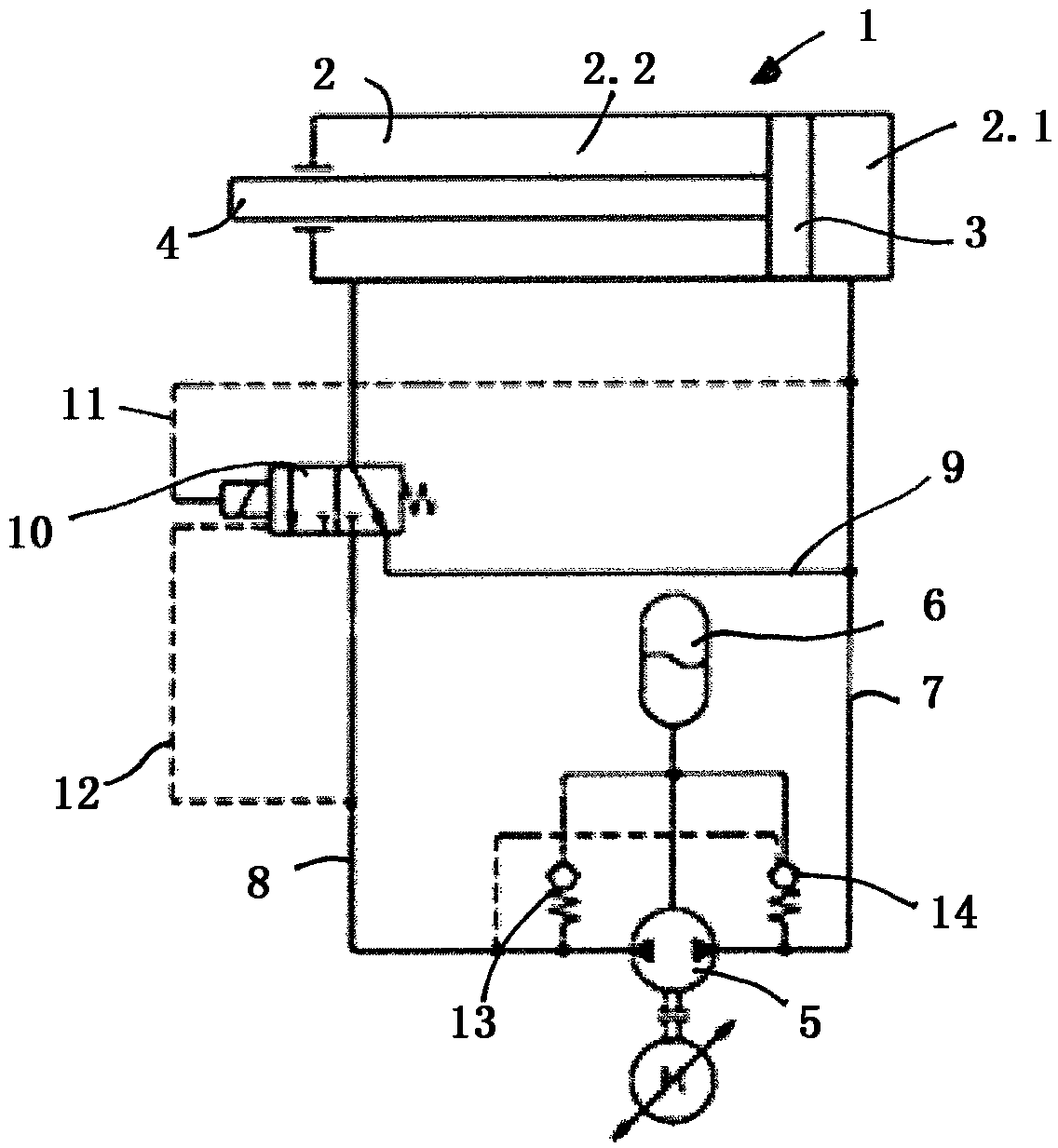

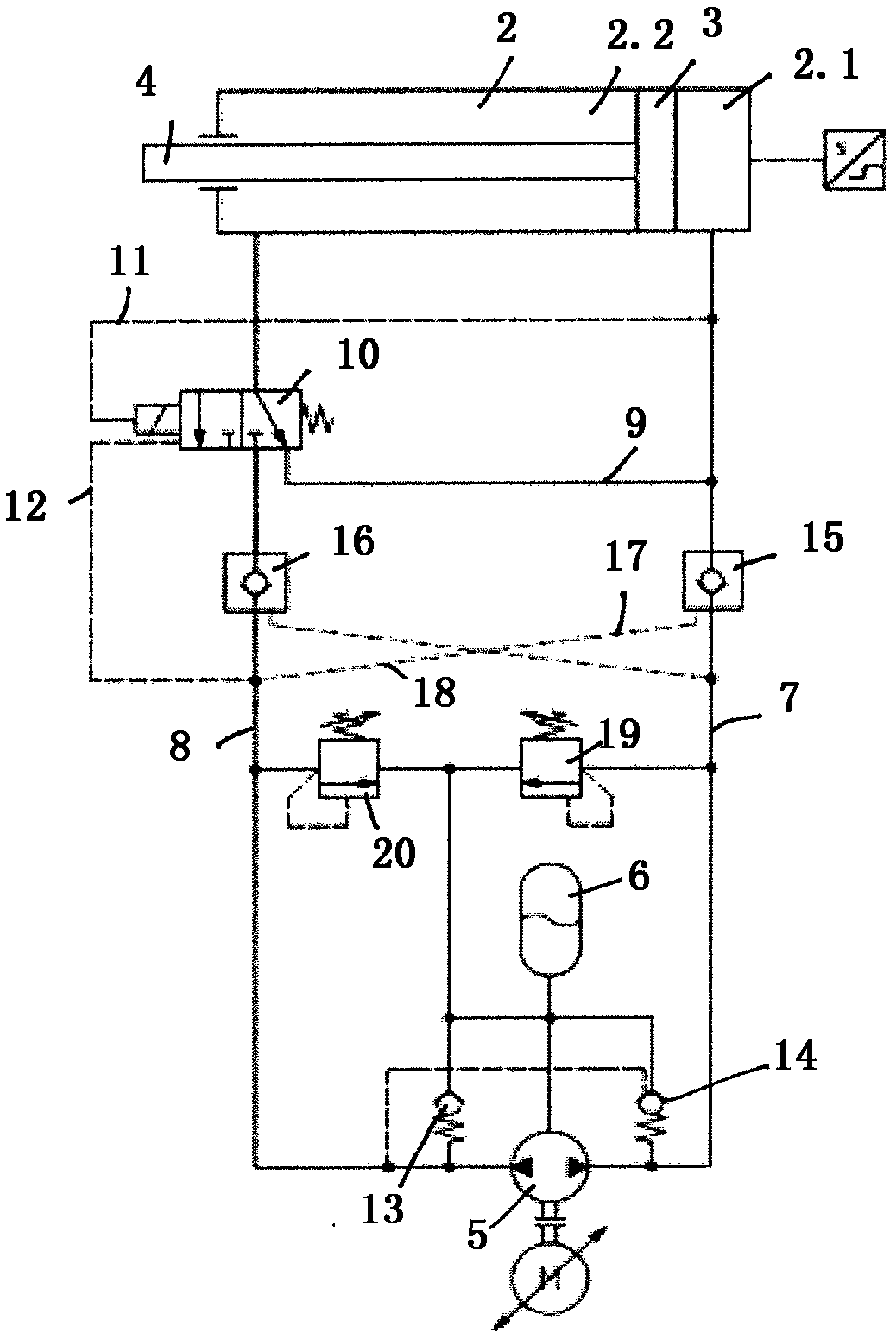

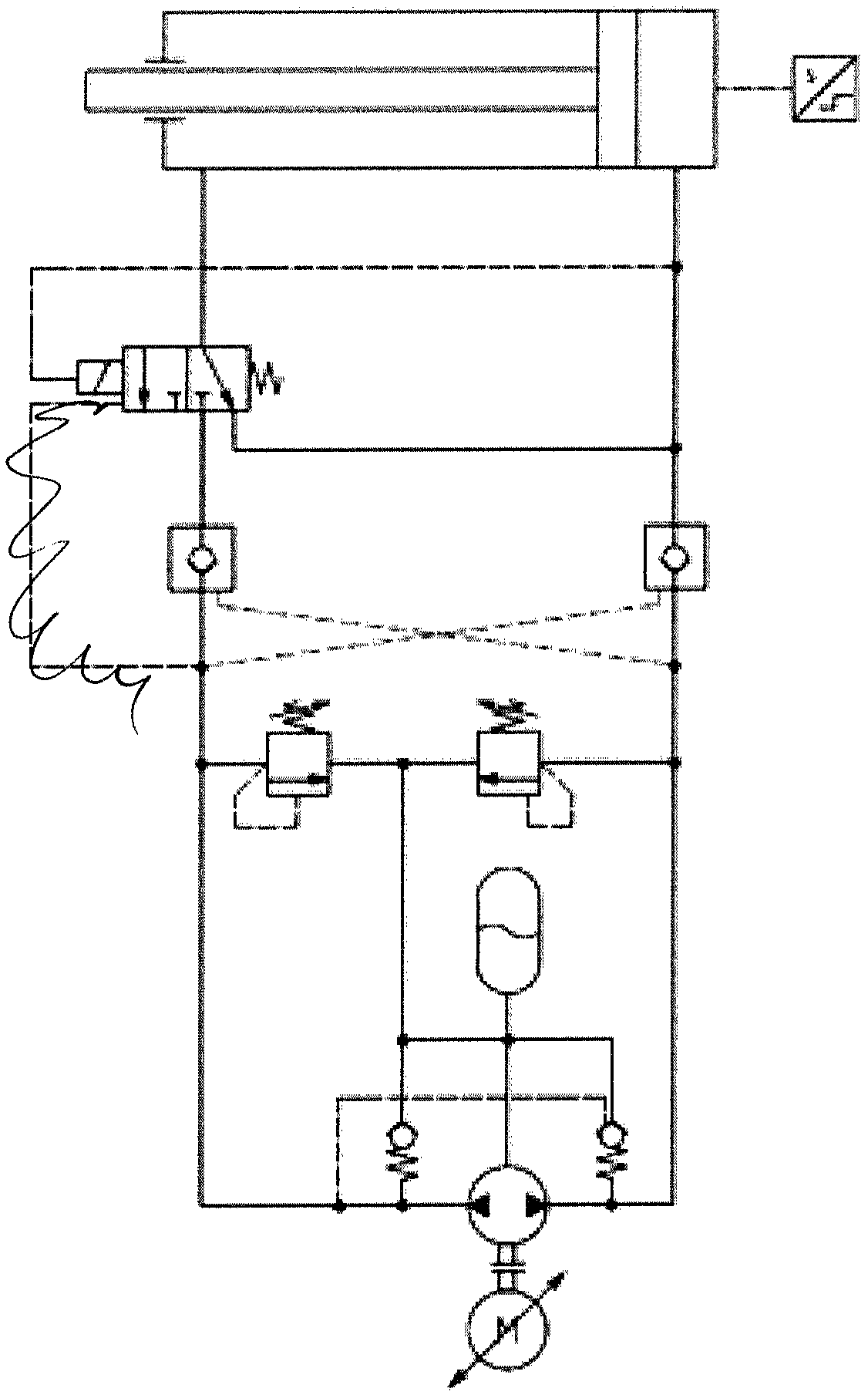

[0031] figure 1 An exemplary embodiment of a hydraulic drive according to the invention is shown in , which has a differential cylinder 1 with a cylinder piston 3 displaceably mounted in a cylinder chamber 2 . The cylinder piston 3 separates the cylinder chamber 2 into a piston side 2.1 and an annular side 2.2. On the piston side 2.1, a fully circular pressure surface acts on the cylinder piston 3, and on the annular side 2.2, an annular pressure surface acts on the cylinder piston 3 due to the piston rod 4 being connected to the cylinder piston 3.

[0032] A hydraulic pump 5 is provided, which is currently operable in two opposite directions of rotation, so that the hydraulic pump 5 can selectively supply hydraulic fluid from the hydraulic fluid reservoir 6 into each of the two hydraulic lines 7 and 8 , through the hydraulic line, the hydraulic pump 5 is connected to the differential cylinder 1 or its cylinder cavity 2 .

[0033] Via the first hydraulic line 7 hydraulic flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com