Automatic feeding device for pig breeding

An automatic, feeding trough technology, applied in animal feeding devices, applications, animal husbandry, etc., can solve the problems of difficult control of the amount of feeding, high labor intensity, easy waste of feed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

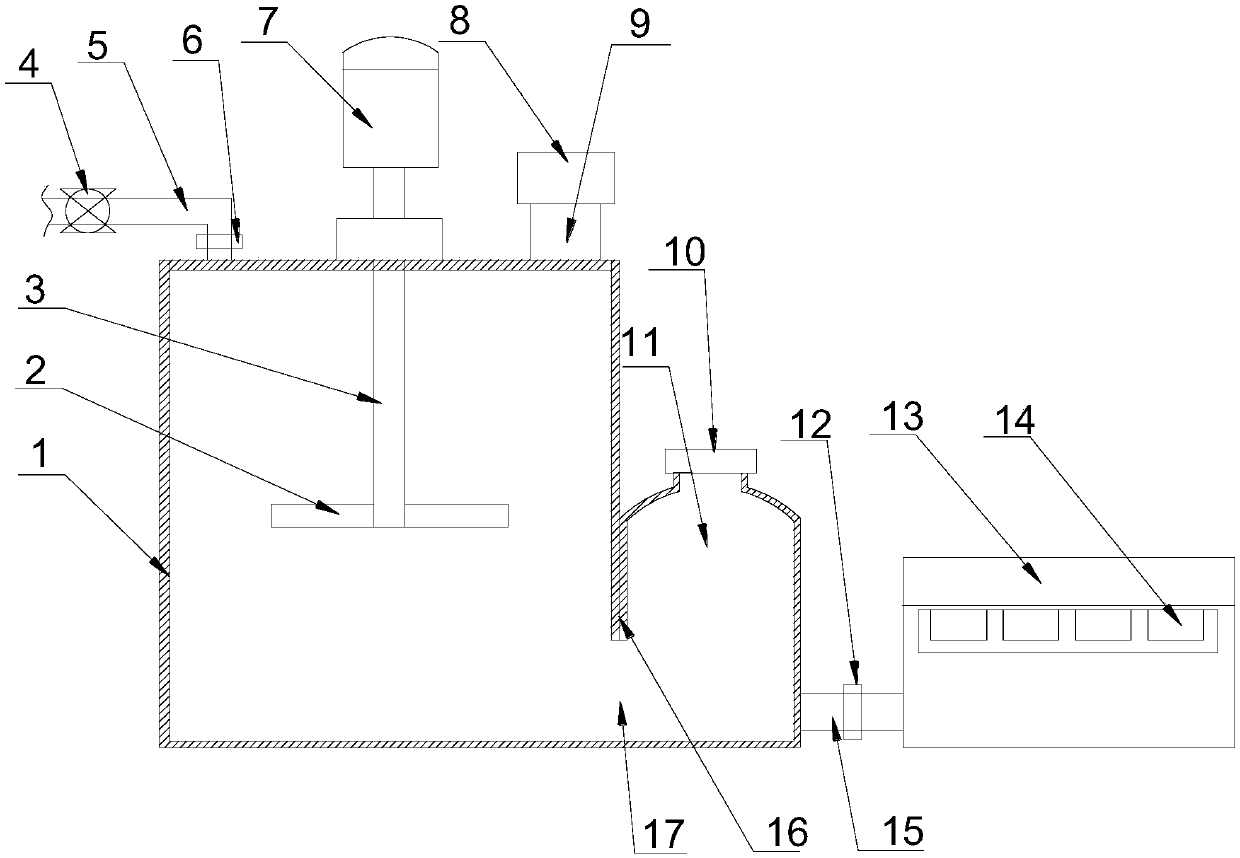

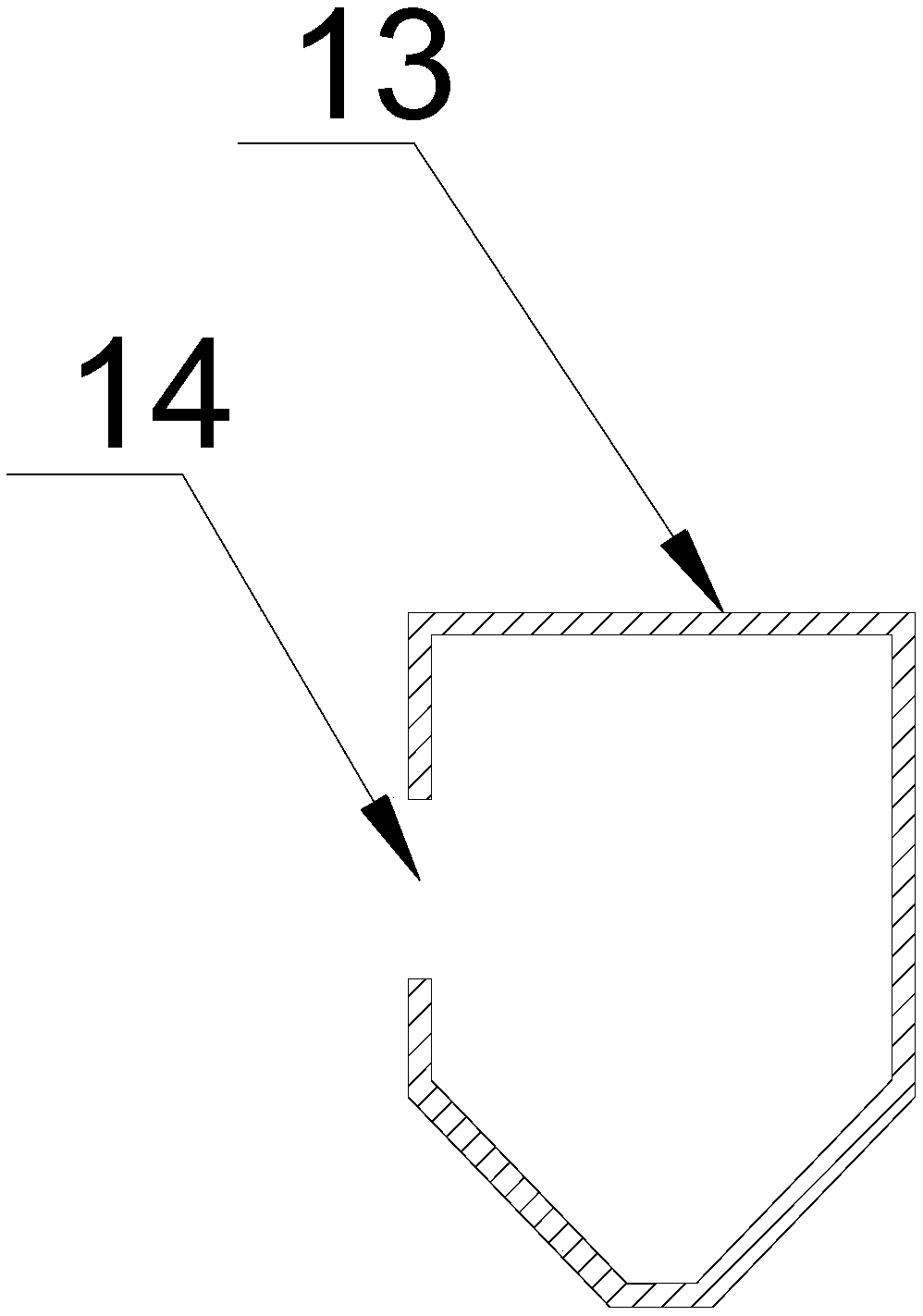

[0028] see Figure 1~2 , an automatic feeding device for pig breeding, comprising a storage tank 1, the upper end of the storage tank 1 is provided with a feed port 9, the feed port 9 is provided with a sealing cover-8, the One side of the storage barrel 1 is provided with a sealed passing barrel 11, and the passing barrel 11 and the storing barrel 1 have a part of a shared side wall 16, and a connecting passing barrel 11 and a storage barrel are arranged below the shared side wall 16. The through hole 17 of the material barrel 1, the side of the material barrel 11 is provided with a connector 15, the connector 15 is provided with a control valve 12, and the end of the connector 15 away from the material barrel 11 is provided with a feeding tank 13, The lower end of the feeding opening 14 of the feeding trough 13 is flush with the upper end of the through hole 17 .

[0029] In the present invention, first close the control valve and seal the feeding bucket, pour pig food into...

Embodiment 2

[0032] see Figure 1~2 , an automatic feeding device for pig breeding, comprising a storage tank 1, the upper end of the storage tank 1 is provided with a feed port 9, and the feed port 9 is provided with a sealing cover-8, the One side of the storage barrel 1 is provided with a sealed passing barrel 11, and the passing barrel 11 and the storing barrel 1 have a part of a shared side wall 16, and a connecting passing barrel 11 and a storage barrel are arranged below the shared side wall 16. The through hole 17 of the material barrel 1, the side of the material barrel 11 is provided with a connector 15, the connector 15 is provided with a control valve 12, and the end of the connector 15 away from the material barrel 11 is provided with a feeding tank 13, The lower end of the feeding opening 14 of the feeding trough 13 is flush with the upper end of the through hole 17 .

[0033] The feeding port 9 is provided with an external thread, and the sealing cover 8 is provided with an...

Embodiment 3

[0039] see Figure 1~2 , an automatic feeding device for pig breeding, comprising a storage tank 1, the upper end of the storage tank 1 is provided with a feed port 9, the feed port 9 is provided with a sealing cover-8, the One side of the storage barrel 1 is provided with a sealed passing barrel 11, and the passing barrel 11 and the storing barrel 1 have a part of a shared side wall 16, and a connecting passing barrel 11 and a storage barrel are arranged below the shared side wall 16. The through hole 17 of the material barrel 1, the side of the material barrel 11 is provided with a connector 15, the connector 15 is provided with a control valve 12, and the end of the connector 15 away from the material barrel 11 is provided with a feeding tank 13, The lower end of the feeding opening 14 of the feeding trough 13 is flush with the upper end of the through hole 17 .

[0040] The upper end of the storage barrel 1 is provided with an air extraction pipe 5, which is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com