Code-scanning intelligent sorting production line of industrial robot

An industrial robot and production line technology, applied in sorting and other directions, can solve problems such as inability to use widely, chaotic sorting items, economic losses, etc., to achieve the effect of fast recognition, prevention of classification confusion, and quality protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

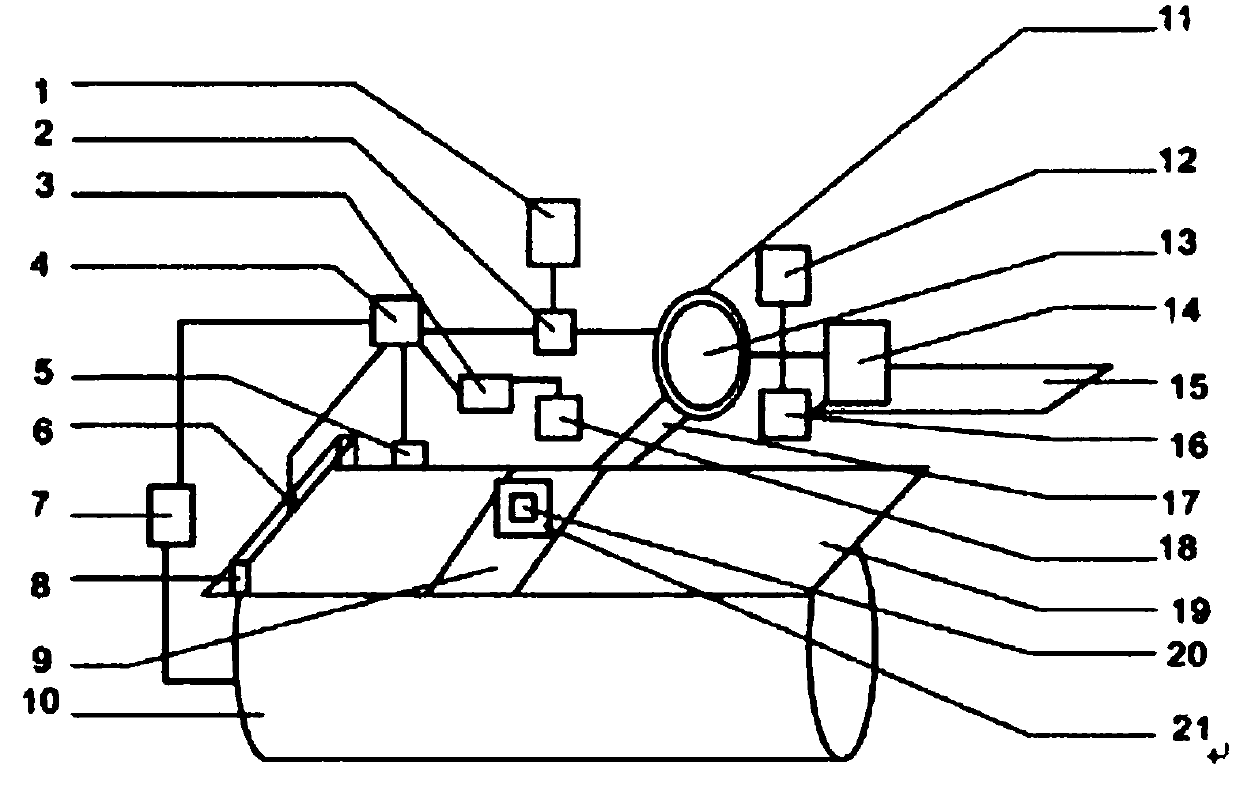

[0008] A code-scanning intelligent sorting production line of an industrial robot according to the present invention will be further described below in conjunction with the accompanying drawings.

[0009] figure 1 In, 1-power supply, 2-multi-gate switch, 3-code scanning signal processing device, 4-control unit, 5-calibration device, 6-positioning device, 7-motor, 8-support frame, 9-code scanning area, 10-Conveyor belt mechanism, 11-Magnetic sucker, 12-Inspection device, 13-Flexible material, 14-Sorting box, 15-Transfer plate 2, 16-Manipulator, 17-Elastic track, 18-Scanner, 19-Transfer plate One, 20-magnetic board, 21-composite label.

[0010] The power supply 1 of a code-scanning intelligent sorting production line of an industrial robot provides electric energy for the device, the multi-gate switch 2 has the function of controlling the opening and closing of the device, the code-scanning signal processing device 3 has the function of processing the code-scanning information,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com