Automatic assembly and detection production line of electric water heater

A technology for automatic assembly and electric water heaters, applied to assembly machines, other manufacturing equipment/tools, metal processing equipment, etc., can solve problems such as accidents, low efficiency, and low product yield, and achieve increased work efficiency and sealing quality Uniformity, obvious effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the invention will be further elaborated below in conjunction with specific embodiments.

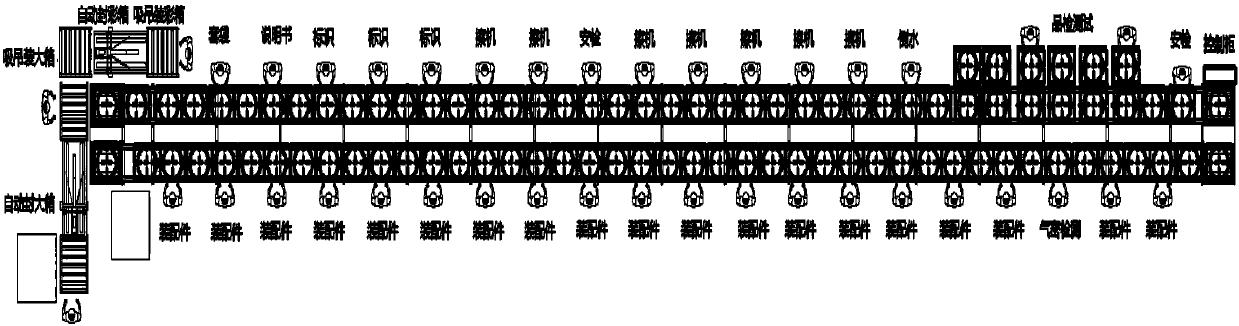

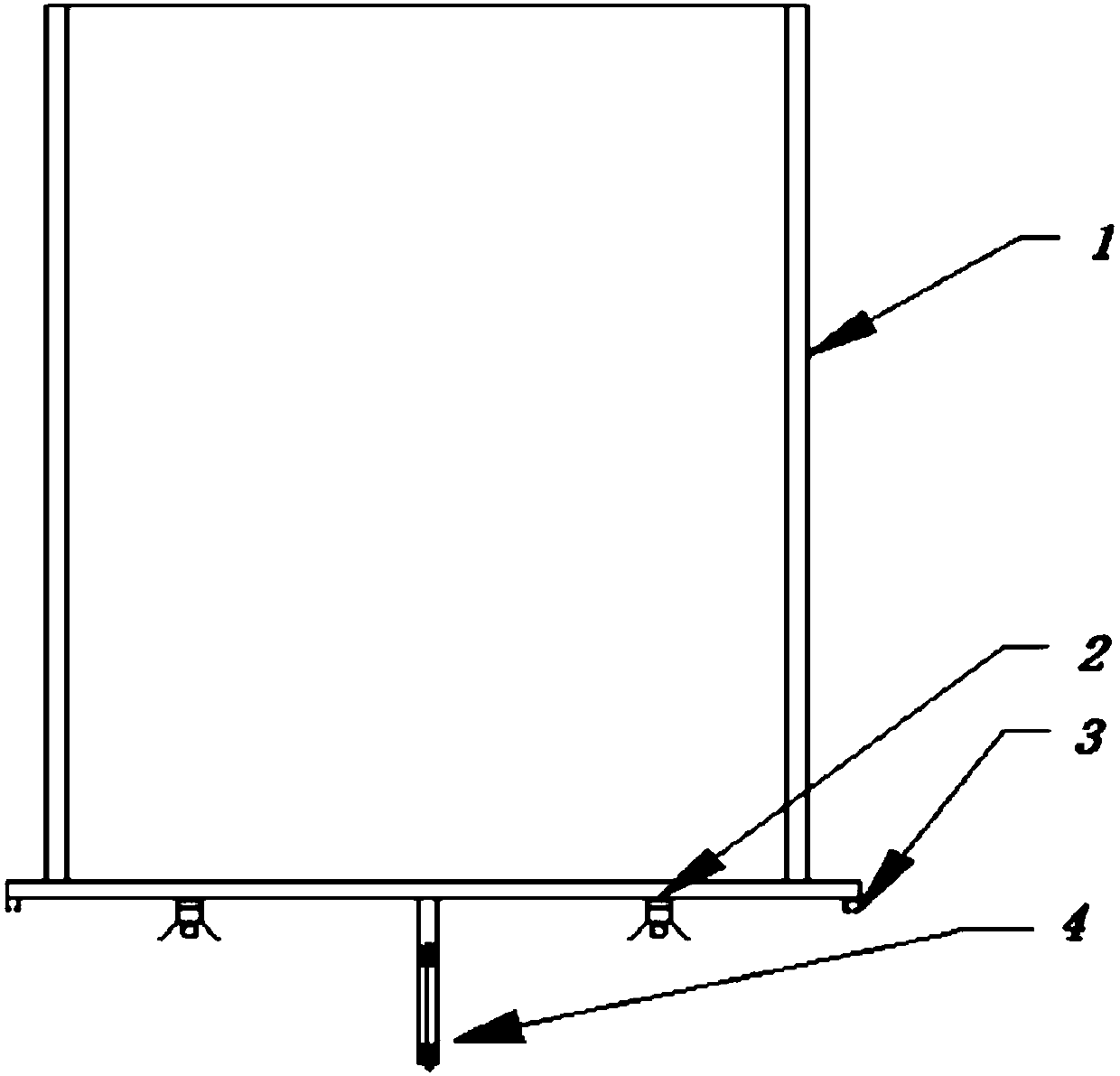

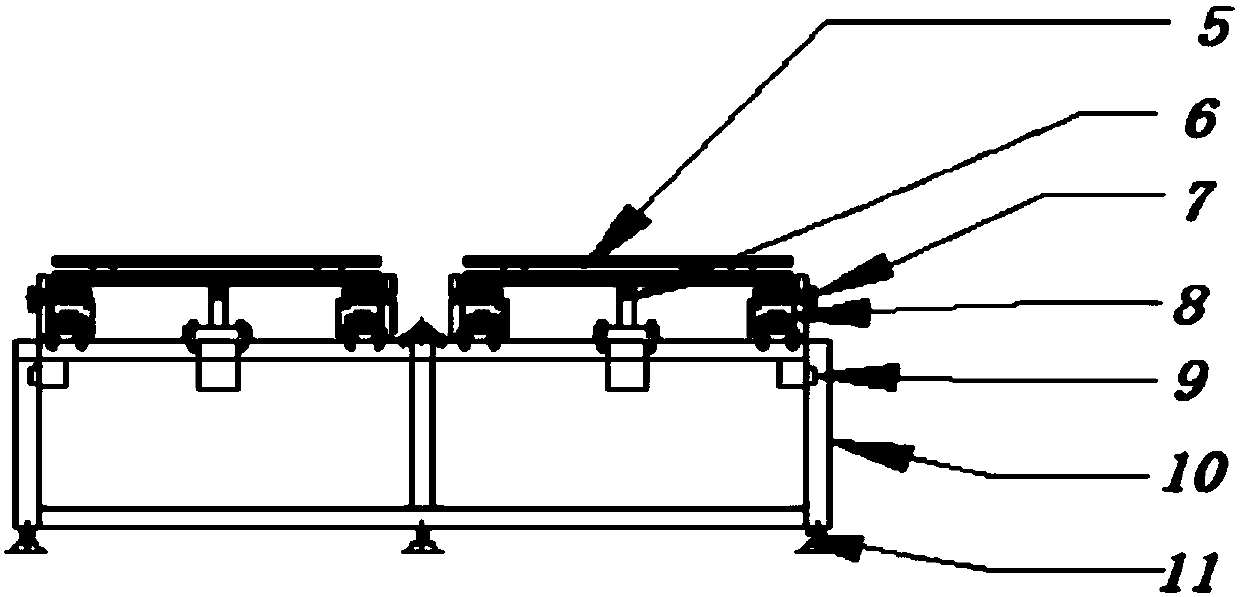

[0028] refer to figure 1 , this specific embodiment adopts the following technical solutions: an electric water heater automatic assembly and detection production line, which is characterized in that it includes a closed ring automatic cloud plate, two sets of horizontal transfer machines, Mitsubishi PLC centralized control system, two sets of automatic sealing machines, There are six sets of testing tables, one set of airtight testing equipment and three sets of vacuum suction cranes.

[0029] Wherein, the closed ring-shaped automatic conveying board includes a tooling board and a manual rotating table, each of which is 80 sets in quantity.

[0030] Wherein, there are two horizontal transfer machines, which are respectively installed at the first and last ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com