Mixed resin defoaming device for wind power blade

A technology of mixing resin and wind power blades, applied in the field of resin defoaming molding, can solve the problems of long defoaming time, increasing production cost, sticking to the top of defoaming tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

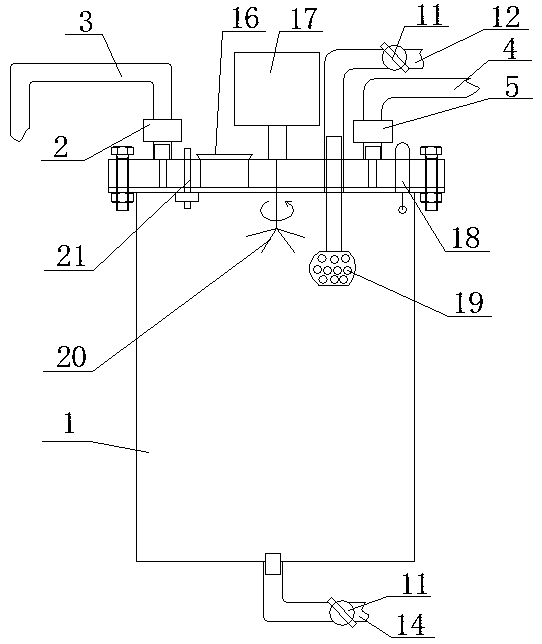

[0036] The core of the present invention is to provide a mixed resin degassing device for wind power blades, which can effectively and quickly degas the resin, prevent the resin from overflowing, and have a better degassing effect.

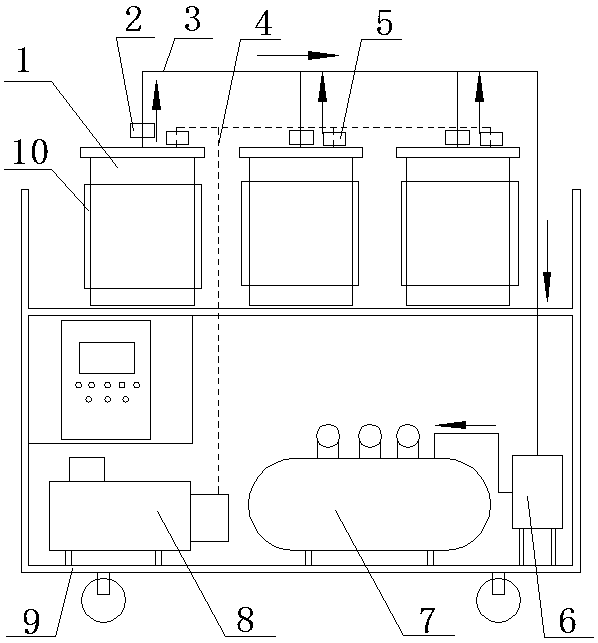

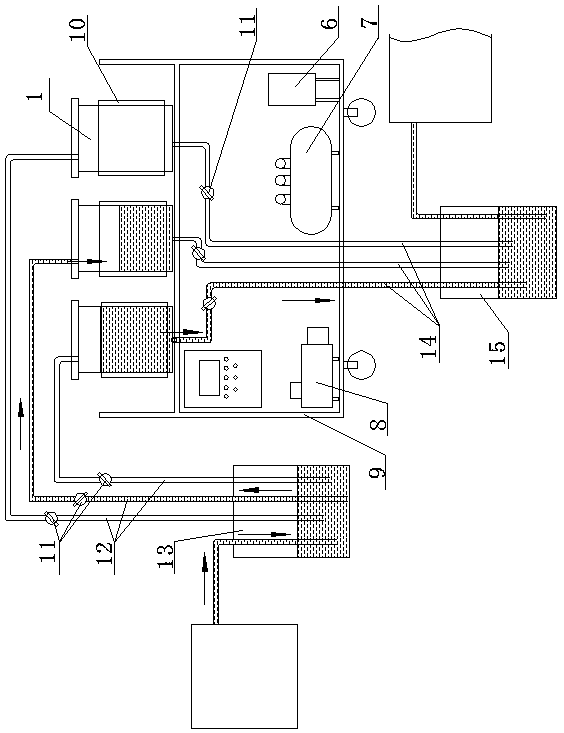

[0037] Please refer to Figure 1-2 , figure 1 It is a schematic diagram of the air extraction or air intake process of the degassing device provided by the present invention, figure 2 It is a schematic diagram of the feeding or discharging process of the degassing device in the present invention. The two figures combine to illustrate the working process of the degassing device as a whole.

[0038] A mixed resin defoaming device for wind power blades, comprising a double-layer operating platform 9, a plurality of defoaming tanks 1 placed on the upper layer of the double-layer operating platform 9, placed on the lower layer of the double-layer operating platform 9 and respectively connected to the defoaming tanks 1 The vacuum pumping part, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com