Automatic assembly machine for precise filter

A precision filter and automation group technology, which is applied in the field of precision filter automatic assembly machines, can solve problems such as low production efficiency, infirmity, and long membrane time, so as to reduce the probability of contamination, ensure product assembly quality, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

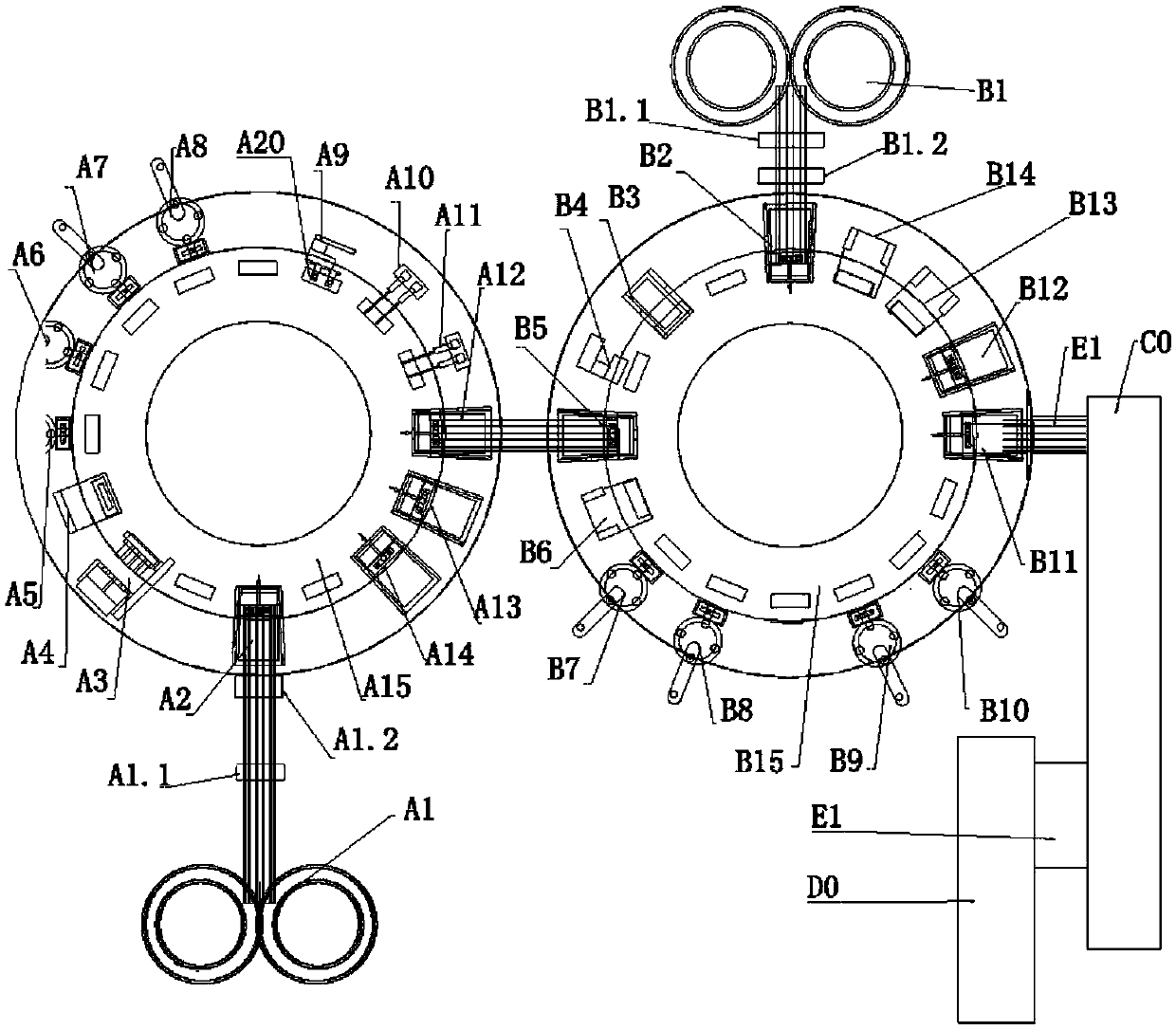

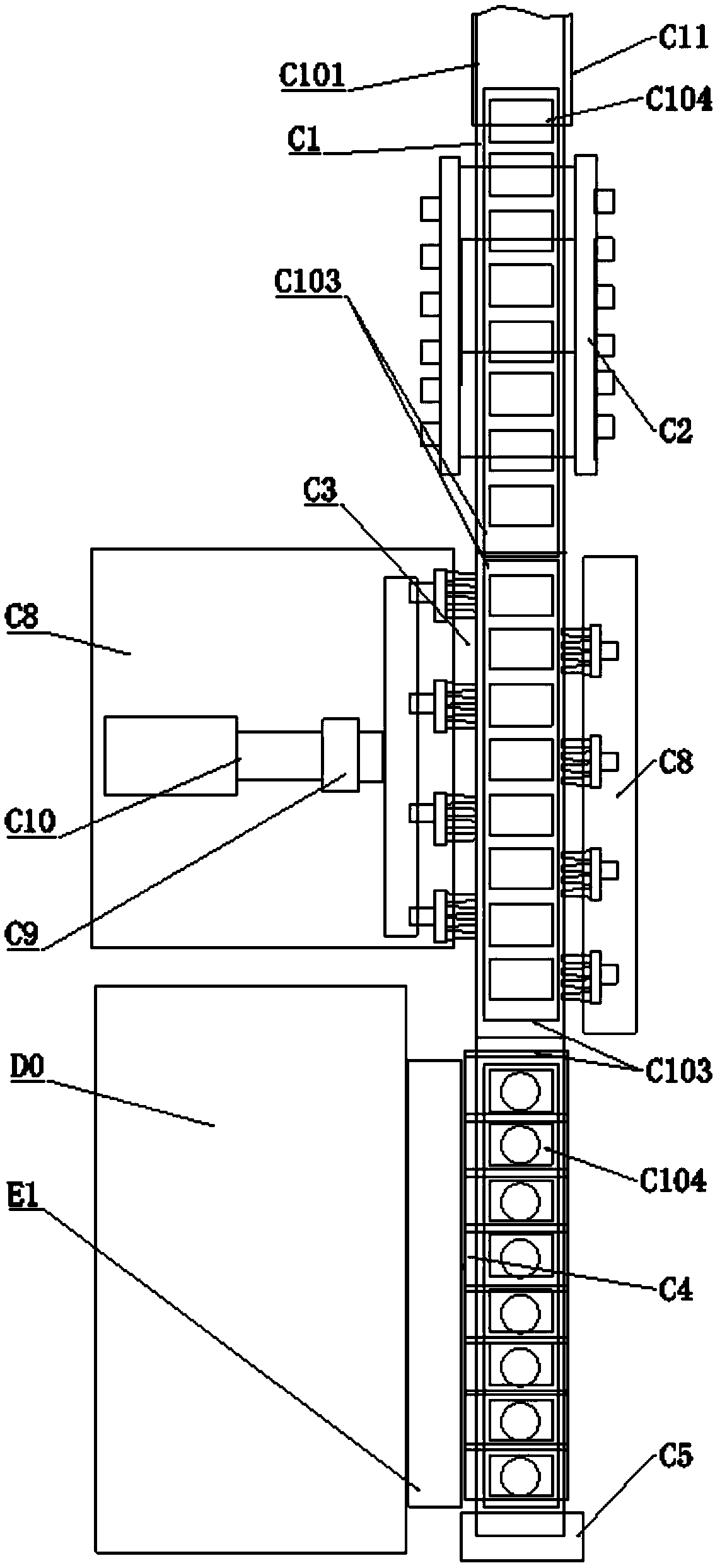

[0009] In order to further understand the technical solutions of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings. Such as Figure 1-8 shown. The precision filter automatic assembly machine of this embodiment includes a joint assembly device and a corresponding control system, and the joint assembly device includes a front assembly device, a reassembly device, a front detection preset device and a rear assembly detection device arranged in sequence.

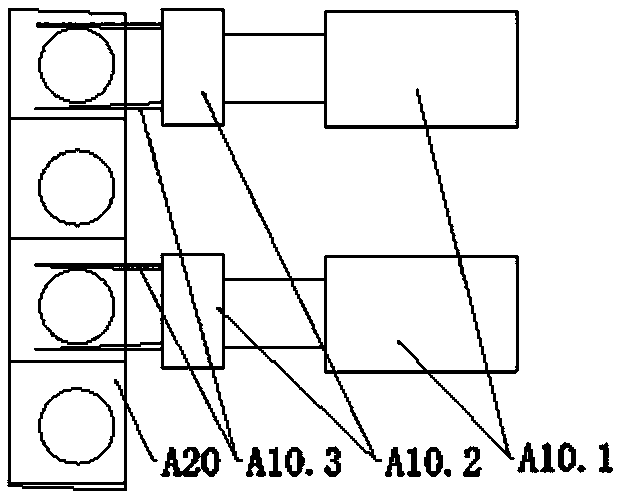

[0010] The front assembling device and the reassembling device respectively include first and second turntables connected with corresponding first vibrating discs A1 and second vibrating discs B1 through corresponding feeding devices. Carriers A20 corresponding to the corresponding devices of each station are wound around the first and second turntables, and the carriers of each station are provided with four work clamps.

[0011] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com