A thermal protection device based on aircraft compartment docking

A technology for thermal protection and aircraft, applied in the field of thermal protection devices based on the docking of aircraft cabins, can solve the problems of limited space in the cabin, high filling ratio coefficient, and difficulty in ensuring design reliability, etc., to achieve reduced internal space, reliable connection, The effect of high loading ratio coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

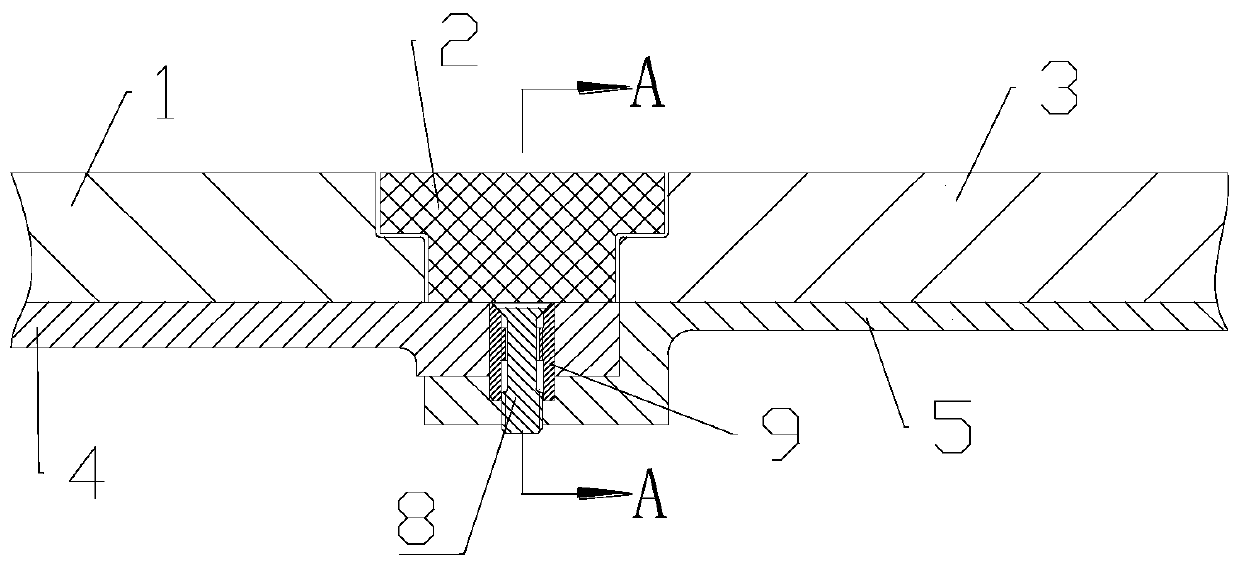

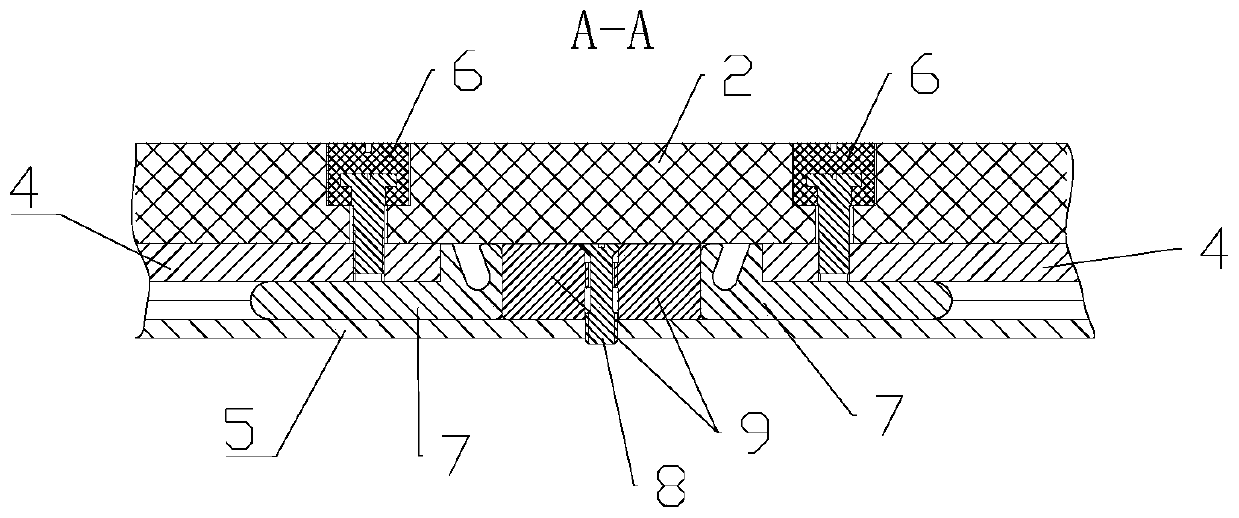

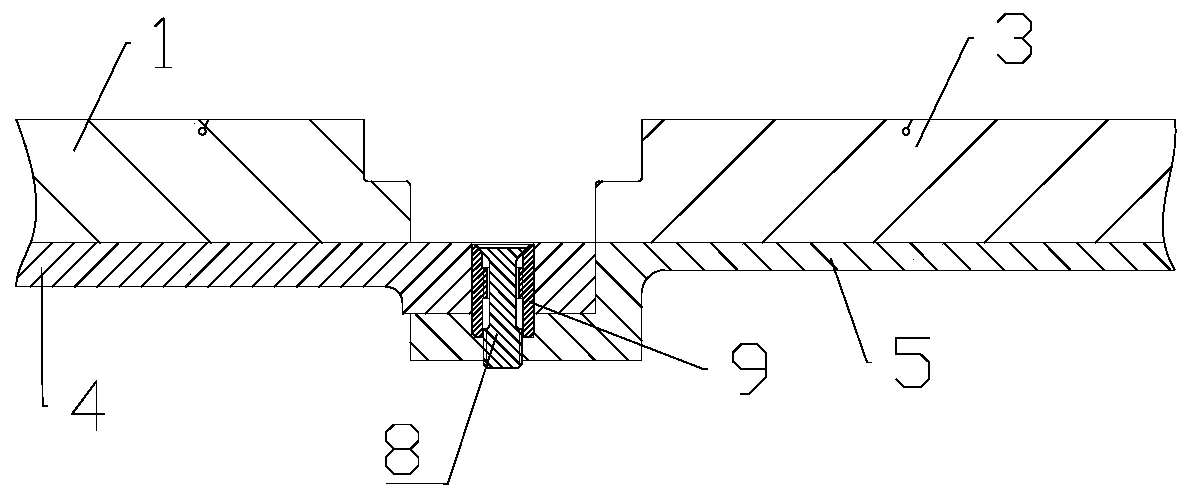

[0038] see Figure 1-7 As shown, the embodiment of the present invention provides a thermal protection device based on aircraft cabin docking, the thermal protection device includes a first cabin shell 4, a second cabin shell 5, a first cabin protective layer 1, The protective layer 3 of the second compartment and the overlapping cover plate 2;

[0039] The first compartment shell 4 is covered with a first compartment protective layer 1; the second compartment shell 5 is connected to the first compartment shell 4; the second compartment shell 5 Covered with a second cabin protective layer 3 connected to the first cabin protective layer 1; the first cabin protective layer 1 and the second cabin protective layer 3 are high-efficiency heat-resistant materials, which They are respectively fixedly installed outside the first compartment shell 4 and the second compartment shell 5 .

[0040] The overlapping cover plate 2 is adapted to fit in the double-sided stepped cavity formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com