Windscreen wiper steel bar separating and feeding device in manufacturing of windscreen wiper

A wiper and wiper technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of large labor burden and low efficiency, and achieve the effects of convenient operation, lightening burden and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

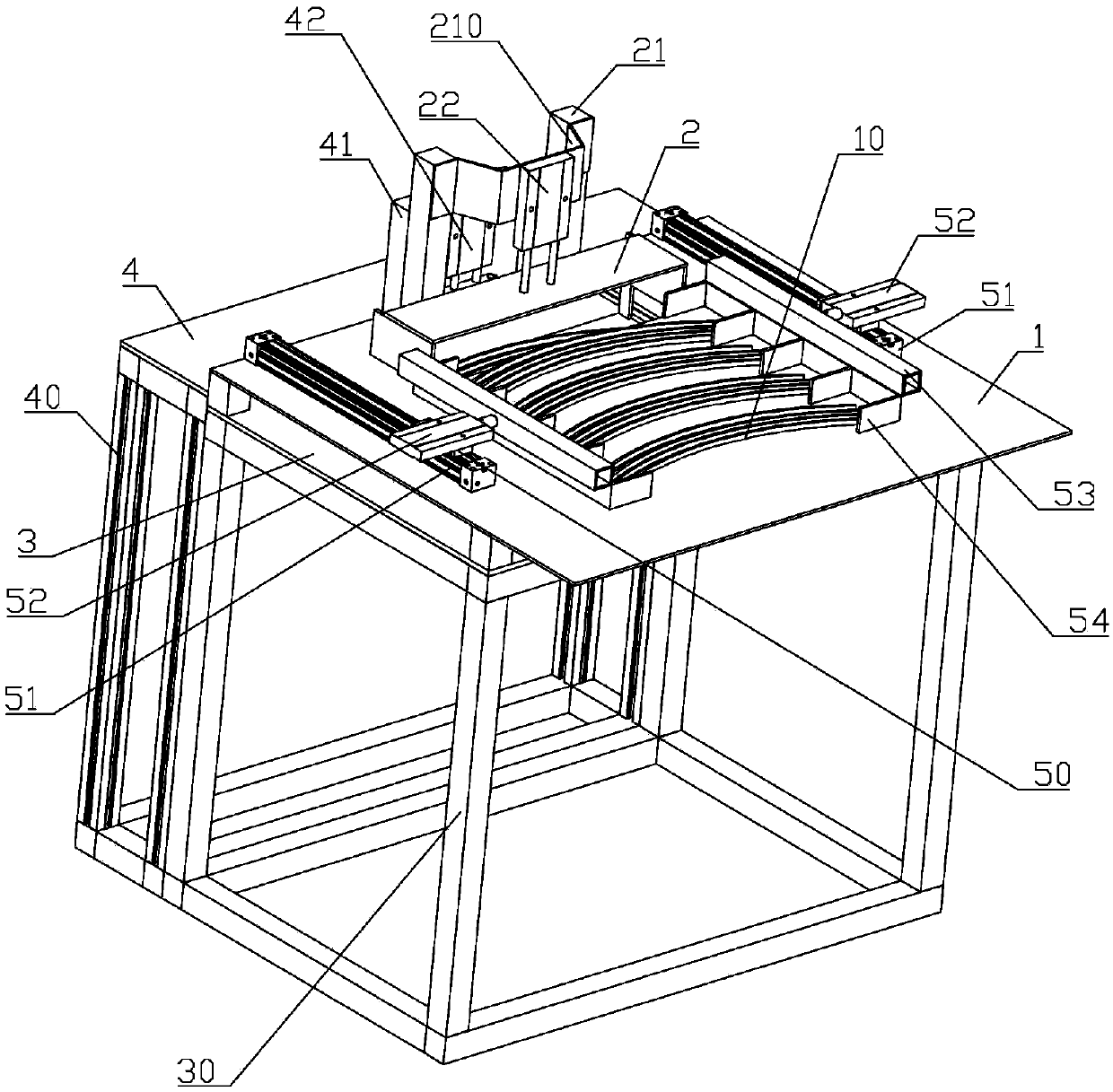

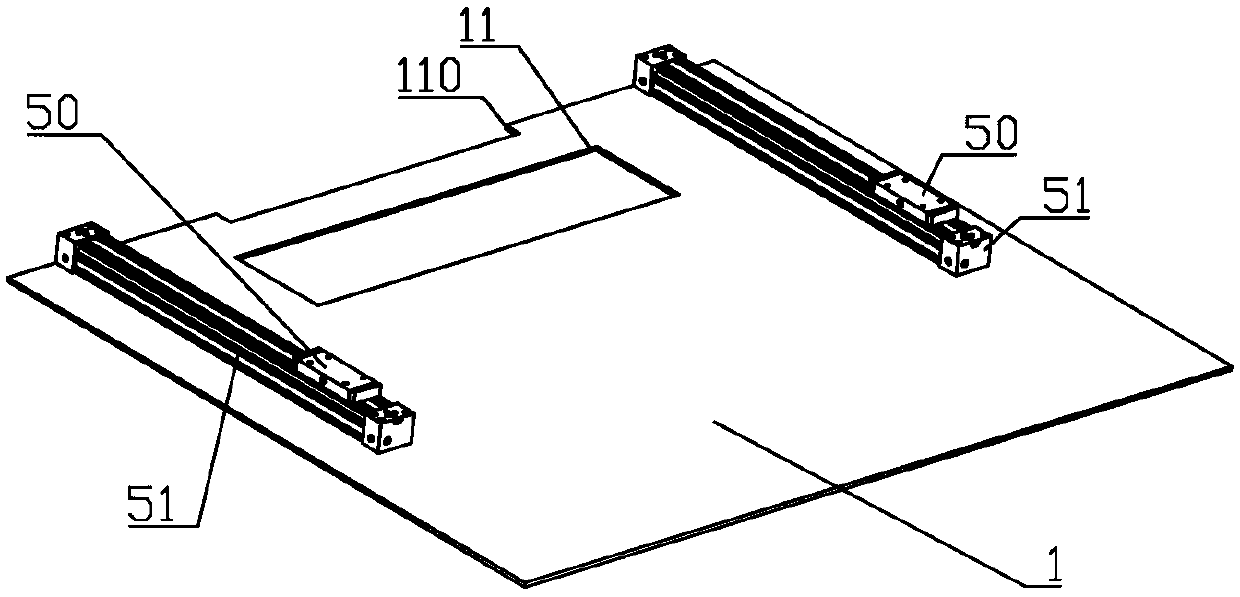

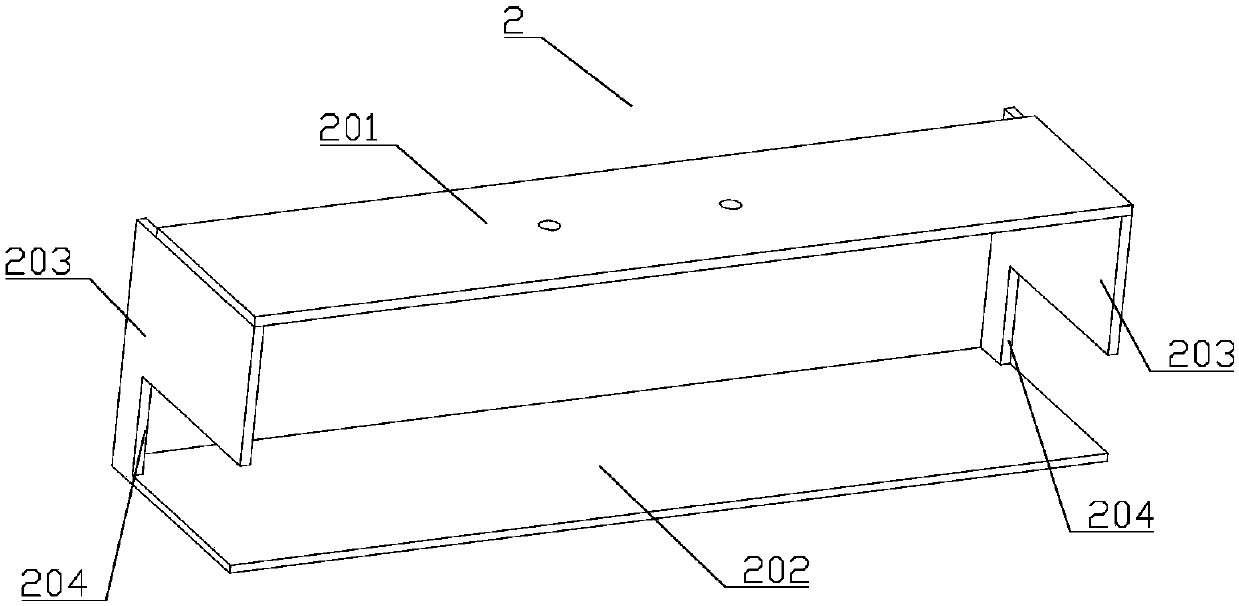

[0035] Such as Figure 1 to Figure 8 As shown, the wiper steel strip separation and feeding device in the manufacture of a wiper blade of the present invention includes a lower panel 3, a first bracket 30 is installed below the lower panel 3, and a mounting panel 4 is provided on one side of the lower panel 3. The mounting panel 4 A second bracket 40 is installed below, the height dimension of the second bracket 40 is greater than the height dimension of the first bracket 30, the lower panel 3 is provided with a second gap 32 near the end of the installation panel 4, and the installation panel 4 corresponds to the second gap 32 A mounting plate 41 is installed on the mounting plate 41. A punch cylinder 42 is installed on the mounting plate 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com