Width-adjustable omni-directional movable portal frame

An all-round, mobile technology, applied in the direction of hoisting equipment braking devices, load suspension components, bottom support structures, etc., can solve problems such as unsatisfactory use effects, hidden safety hazards, and low strength, and achieve reduced production and operation costs, Improve work efficiency, quick disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

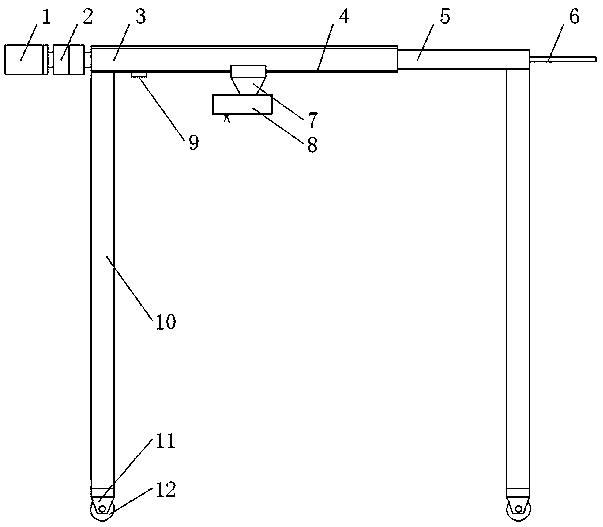

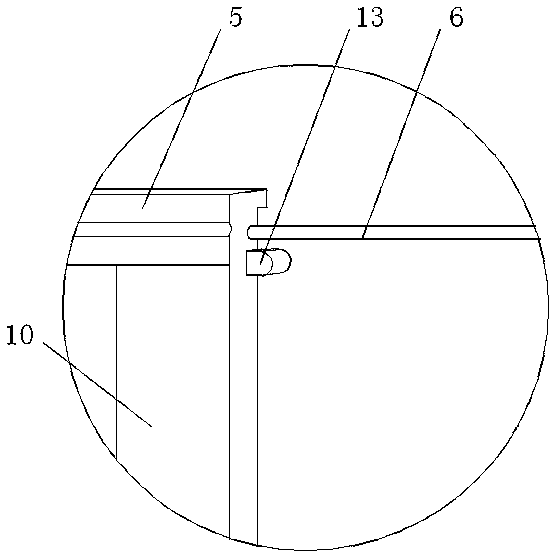

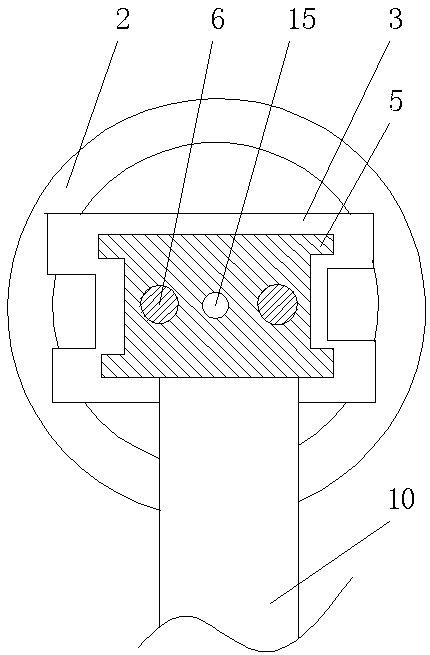

[0028] See attached Figure 1-6 The gantry disclosed by the present invention is a gantry structure whose overall width can be adjusted at will and can move in all directions.

[0029] The all-round mobile gantry with adjustable width includes a support adjustment mechanism and a moving mechanism, wherein the support adjustment mechanism realizes the support and width adjustment functions of the entire gantry frame body, and the moving mechanism realizes the omnidirectional movement of the gantry frame body. The bottom of the support adjustment mechanism is equipped with a moving mechanism, the support adjustment mechanism is provided with a hanging block 7, and an electric hoist 8 is hoisted on the hanging block.

[0030] The support adjustment mechanism includes a beam and a support beam. The beam includes a fixed beam 3 and a moving beam 5. Both th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com