Membrane component tank with dielectrophoresis pre-filtration structure

A dielectrophoresis and pre-filtration technology, which is applied in the directions of water/sewage multi-stage treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the complex and inconvenient installation and manufacturing, increase the occupied space, and reduce the manufacturing cost. Cost and other issues, to achieve the effect of easy processing and manufacturing, guaranteed effect, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

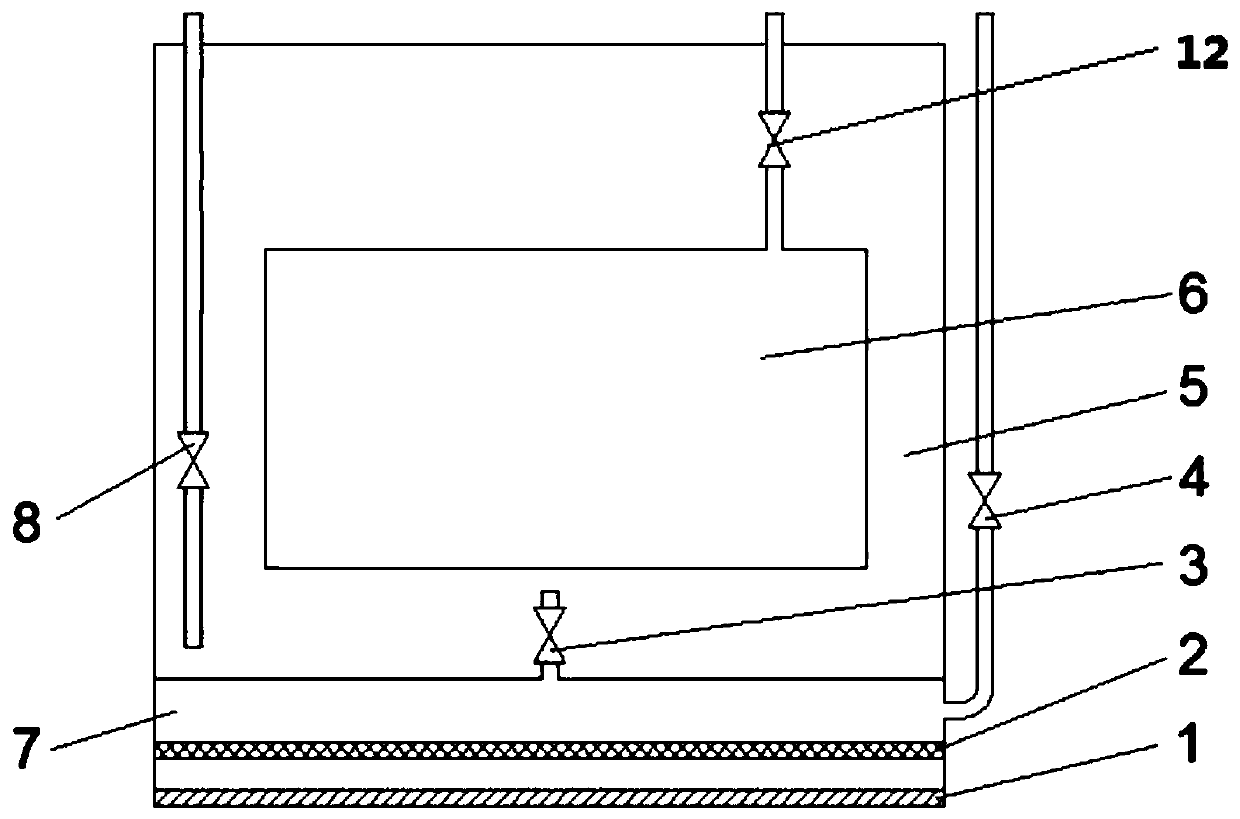

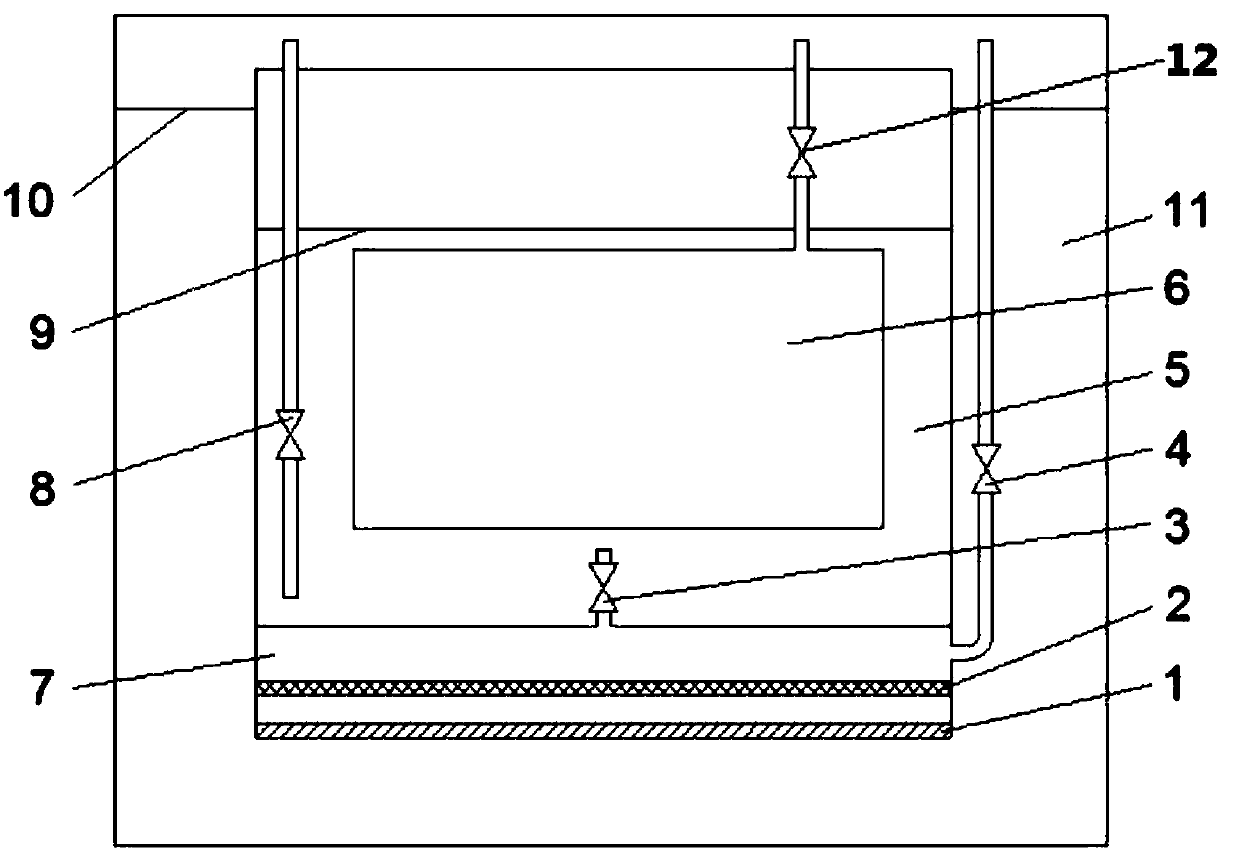

[0028] A membrane module box containing a dielectrophoresis pre-filtration structure includes a membrane box 5 and a pre-filter cavity 7. The pre-filter cavity 7 is located at the bottom of the membrane box 5 and is connected to the membrane box 5 through a water inlet valve 3.

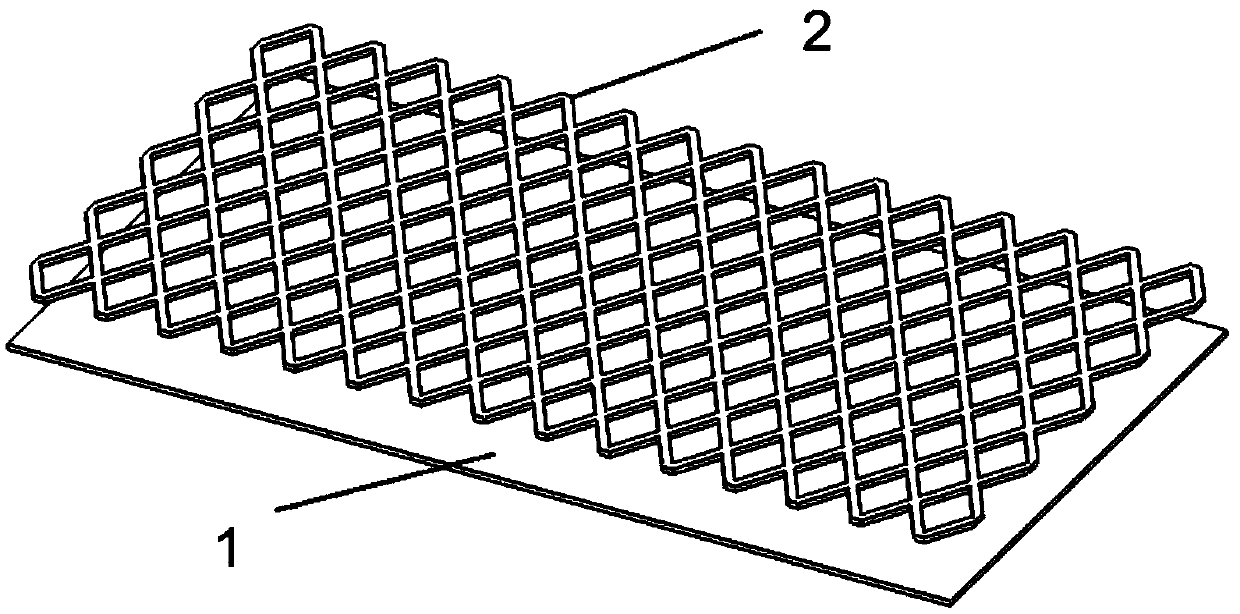

[0029] A dielectrophoresis filter structure is installed in the pre-filter cavity 7. The dielectrophoresis filter structure includes a metal stretched mesh electrode plate 2 and a metal porous membrane structure electrode plate 1 arranged in parallel up and down, a metal stretched mesh electrode plate 2 and a metal The porous membrane structure electrode plates 1 are respectively connected to different output terminals of the AC power supply, and the metal stretched mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com